USER MANUAL

USER MANUAL

This equipment measures high-speed analog and digital signals in laboratory or mobile environments. It may also be used in other areas, for example when troubleshooting or performing field tests. The use of the DECAQ measurement system requires an understanding of the measurement chain and signal analysis.

Even though the DECAQ has been designed to withstand rough handling, it is a sensitive and complex electronic instrument and must be handled with care.

The DECAQ must be powered down for 30 seconds before any Module or Board can be inserted or removed. The DECAQ hardware is not hot-swappable.

Care has been taken to provide reasonable ESD protection. However, all DECAQ components are sensitive to ESD and may be damaged by an ESD discharge.

To avoid damaging the DECAQ, antistatic precautions must be followed. This is especially important when swapping Modules. However, care must also be taken when swapping combined System Controller and Power Supply boards, Signal Conditioning boards or Synchronization Engines. Antistatic precautions are advisable when connecting cables or sensors to Modules.

Precautions include:

Do not use a damaged power supply, cable or any other DECAQ component.

The DECAQ may not be operated or stored in flammable environments (fumes, gasses, liquids, etc.), excessively harsh environments (corrosive, ambient temperature above 50 °C, radioactive, hydraulic fluid, etc.), or excessively damp environments.

The radiated output power of the DECAQ is within acceptable radio frequency exposure limits and is intended to be used 300 mm away from a human operator.

Depending on the configuration, the DECAQ may become heavy and could pose a danger if not stored or transported in a responsible manner. Please use the handle provided. When using the removable handle, ensure it is properly installed and the locking mechanisms are engaged.

Mecalc supports environmentally sound recycling. Recycle or dispose of DECAQ Batteries through a reputable service provider or contact your supplier (Mecalc Representative or Channel Partner) for assistance. This is also applicable to any other broken or unused components.

The products in this manual do not contain any mercury or mercury compounds.

The products in this manual do not contain any substances listed as Class I or Class II specified chemical substances under the Japan Chemical Substances Control Law (CSCL).

Mecalc believes in ethical and responsible practices and is committed to promoting economic, environmental and social justice at all levels of our supply and manufacturing processes.

As part of this commitment, we:

Support the “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas”

Have conducted a Conflict Mineral report using the Responsible Minerals Initiative’s Conflict Minerals Reporting Template (CMRT) and Extended Mineral Reporting Template (EMRT)

Require all our suppliers to source minerals exclusively from smelters or refiners that comply with principles highlighted in the “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas”

The DECAQ measurement frontend is classified as “a digital device used exclusively as industrial, commercial, or medical test equipment”. Therefore, according to CFR47 section 15.103 the DECAQ measurement frontend is exempt from the specific technical standards in CFR47 part 15. Even though the starred combinations have not been explicitly certified for FCC/IC compliance, Mecalc did endeavour to have the device meet the specific technical standards. All DECAQ measurement frontends may therefore be used in the USA or Canada provided that according to CFR47 section 15.103, “the operator of the exempted device shall be required to stop operating the device upon a finding by the Commission or its representative that the device is causing harmful interference”.

The WLAN Module used in the DECAQ has been pre-certified for use in Japan and South Korea.

The products described in this manual are not designed, developed, or intended for military use. They are not included on the United States Munitions List (USML) as defined under the International Traffic in Arms Regulations (ITAR), 22 CFR Parts 120–130.

All products are classified as Commercial Off-The-Shelf (COTS) items. Additionally, these products are regulated under the Export Administration Regulations (EAR) and are classified under Export Control Classification Number (ECCN) 3A992.a. This classification applies to general-purpose electronic devices intended for civilian and industrial applications.

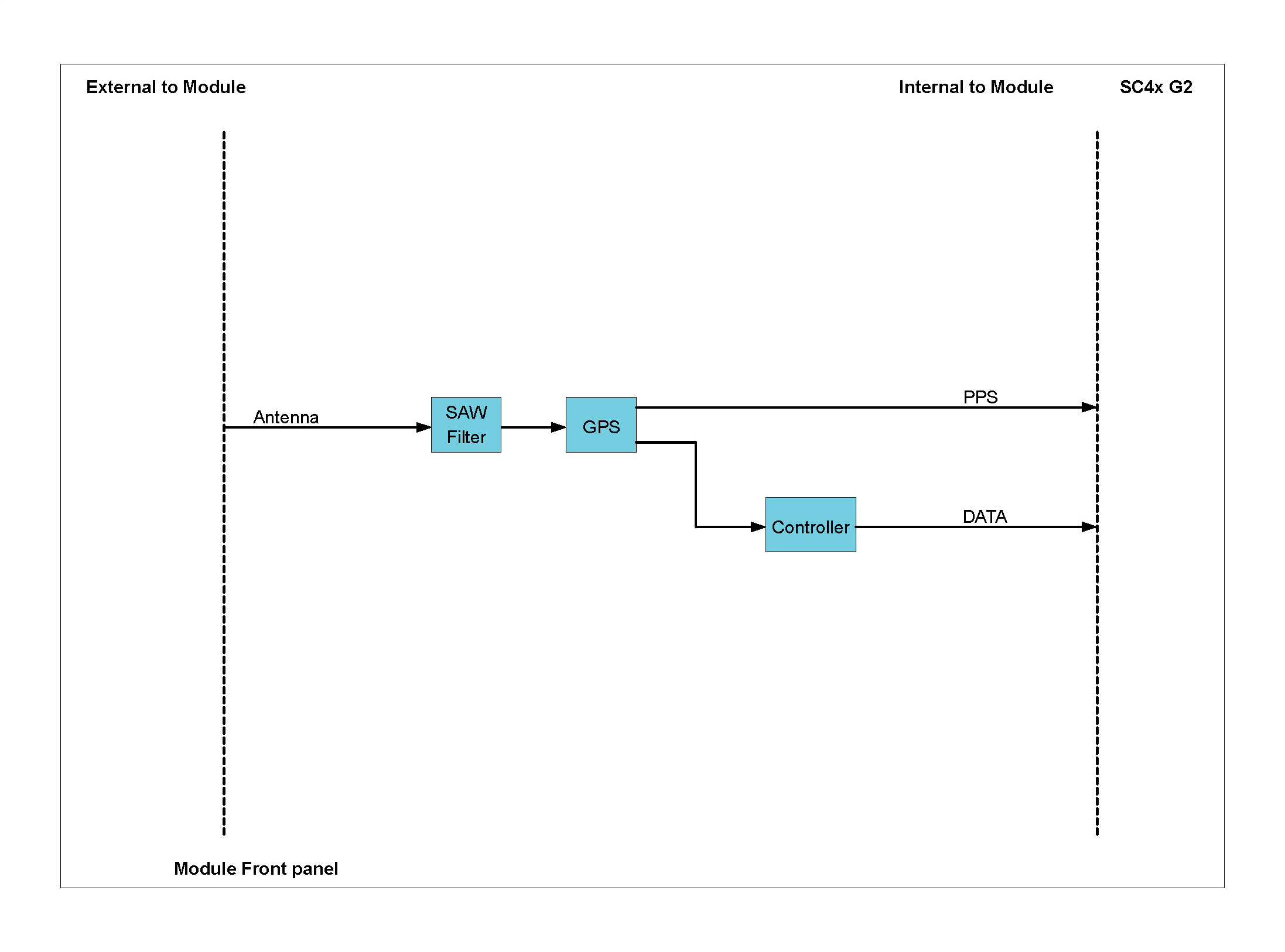

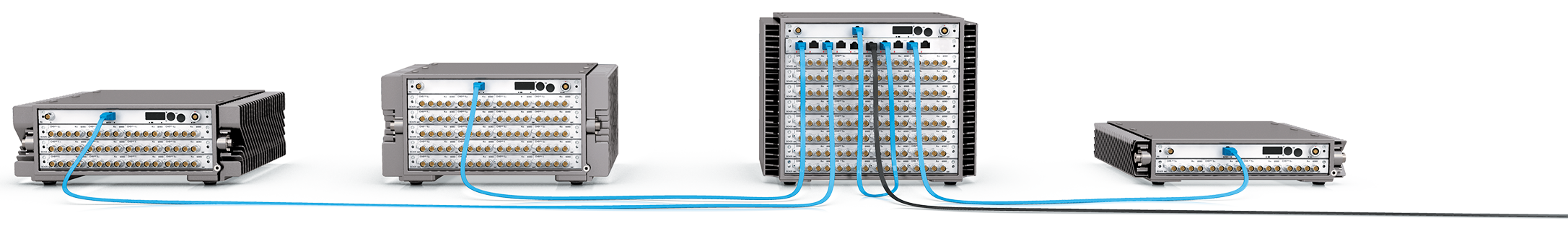

DECAQ systems are compact data acquisition systems which measure high-speed analog and digital signals. Designed for portable measurement, troubleshooting, field testing and complex laboratory applications, DECAQ systems are capable of housing up to 216 channels in a single chassis. Each DECAQ system can securely connect, communicate and be controlled using either the User Interface, a laptop or smart device, as well as to store data for later playback.

A typical user will have an understanding of measurement chain and signal analysis.

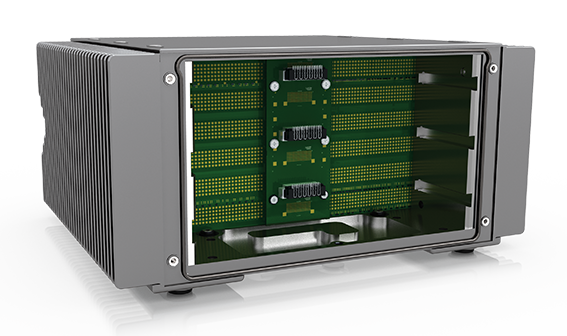

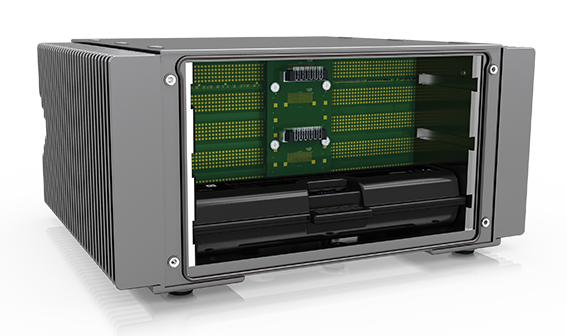

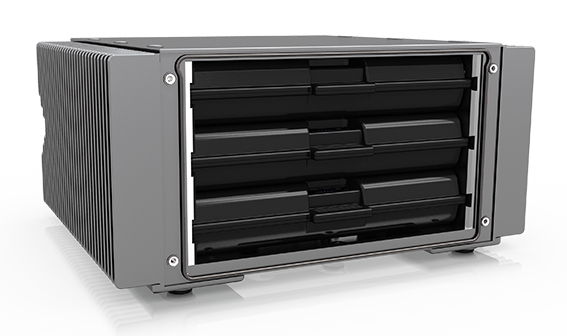

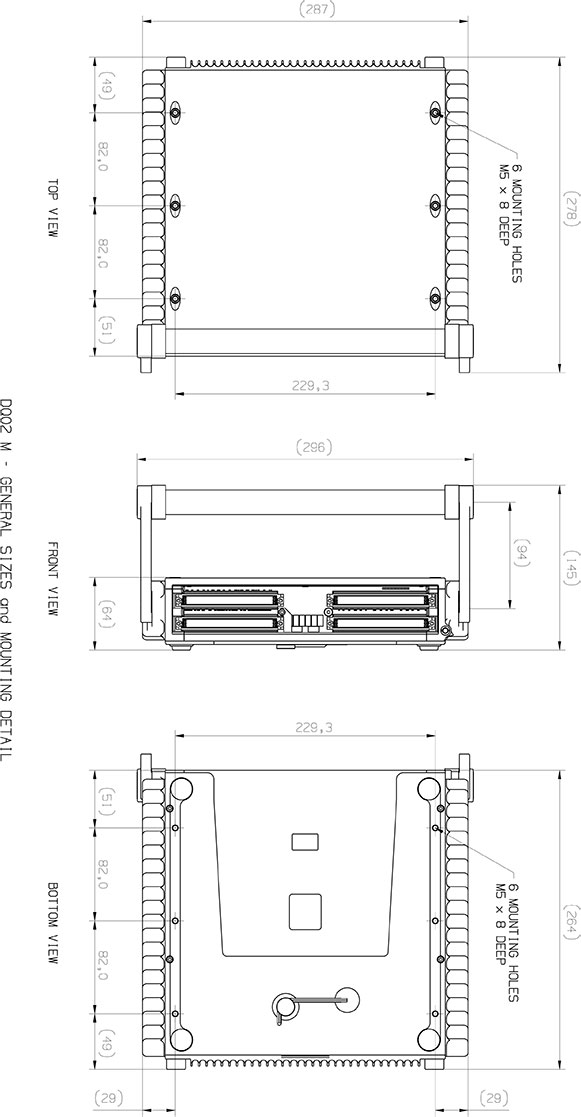

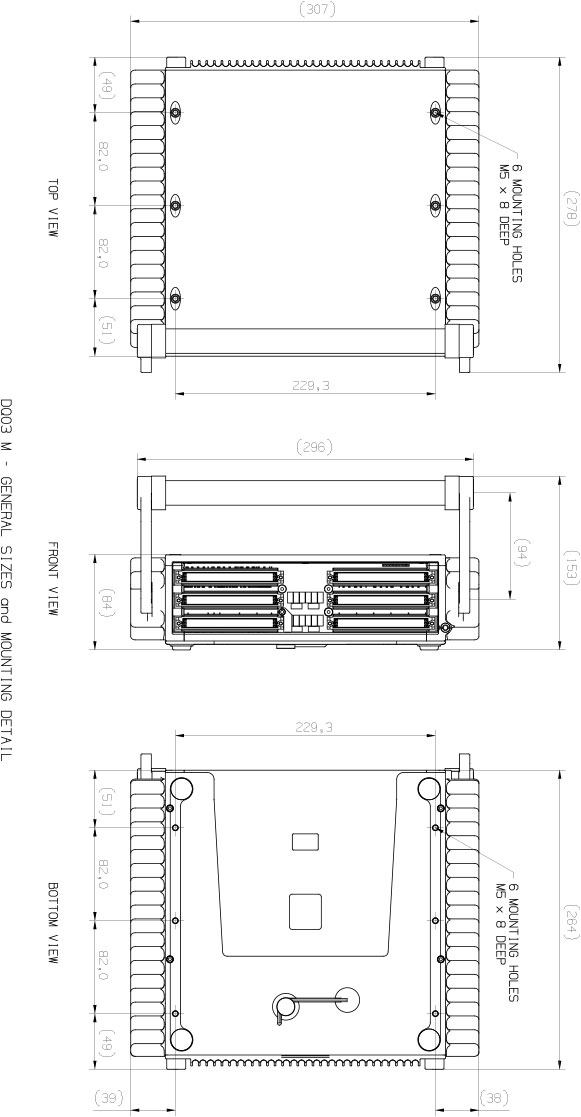

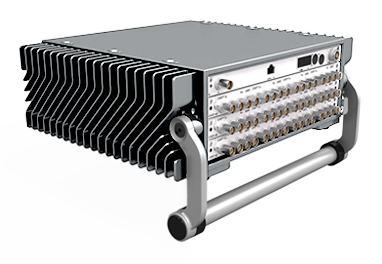

The DECAQ comes in 4 chassis sizes, namely the DECAQ 2-slot, 3-slot, 4-slot and 6-slot chassis. This section shows views for each chassis size.

Rack Mount versions of the DECAQ Mainframes are shown in section 5.

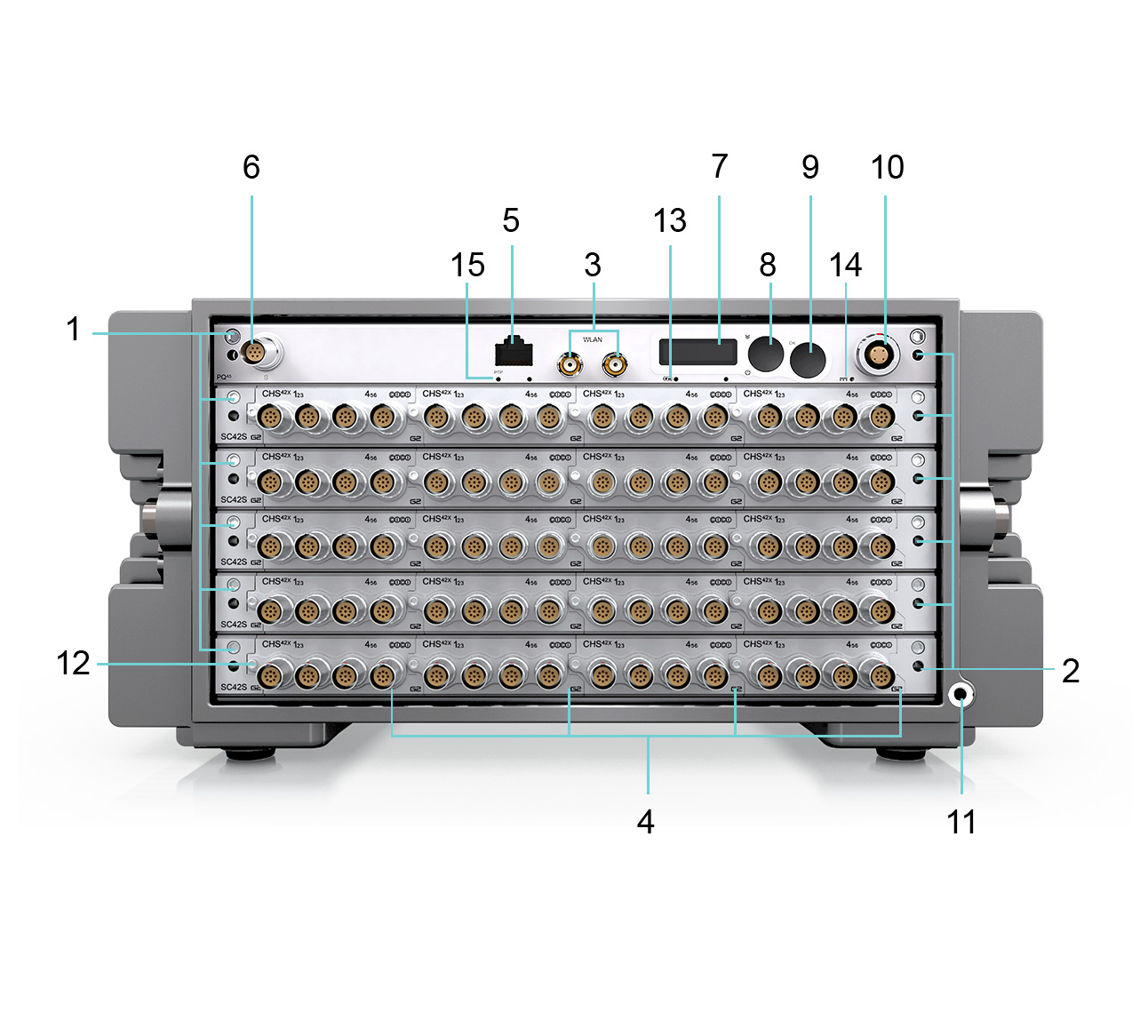

This section highlights front view features common to all systems.

1. Extraction Jacking Screw To remove the board from the chassis during system maintenance, tighten the extraction jacking screw until the board ejects.

2. Portal for Thermal Expanders Ensure the thermal expanders have been properly fastened before conducting measurements. See Handling Guidelines for Effective Cooling for more information.

3. Built-in Wi-Fi Antenna Connectors Reverse Polarity SMA Female connectors for IEEE 802.11 a/b/g/n WLAN communication. The antenna should have a Reverse Polarity SMA Male connector.

4. QModule slots Featured QModule: Slot 2 CHS42X:6 Channel Charge or ICP®/IEPE and Voltage Input Amplifier See Measure: Signal Conditioning for more information.

5. Ethernet (Ethernet / PTP) Ethernet 1000BASE-T PTP (Precision Time Protocol) IEEE 1588-2008 PTP synchronization over Ethernet. See Synchronization for more information.

6. S-Port Connect to the ATTOQs via the S-Port.

7. User Interface Display Receive system information and execute commands via the User Interface. See Navigating the DECAQ’s User Interface Display for more information.

8. User Interface Scroll Button Use

the Scroll Button

( )

to switch on the DECAQ and scroll through User

Interface menu options. See Navigating the DECAQ’s

User Interface Display for more information.

)

to switch on the DECAQ and scroll through User

Interface menu options. See Navigating the DECAQ’s

User Interface Display for more information.

9. User Interface OK Button Confirm User Interface menu option selections using the OK Button. See Navigating the DECAQ’s User Interface Display for more information.

10. Power LEMO® Power the DECAQ with an external power source via the Power LEMO®. See Power for more information.

11. Earth Terminal Beware of ground loops as the system is earthed via the Mean Well power supply. Consider connecting the Earth Terminal to the building safety earth if there is any risk of electrical shock in the testing environment. It can be used to provide a ground reference for analog signal measurements, if appropriate settings are applied to the relevant QModule channels. It can also be used in some cases to decrease noise on analog signals.

12. QModule Jacking Screw Insert and remove QModules using a Jacking Screw. See Inserting and Removing QModules for more information.

13. Battery Status LED Provides information about the internal battery to the User.

14. Power Supply Status LED Provides information about the power supply to the User.

15. Ethernet / PTP Status LED Synchronize DECAQ systems with PTP (Precision Time Protocol) See Synchronization for more information.

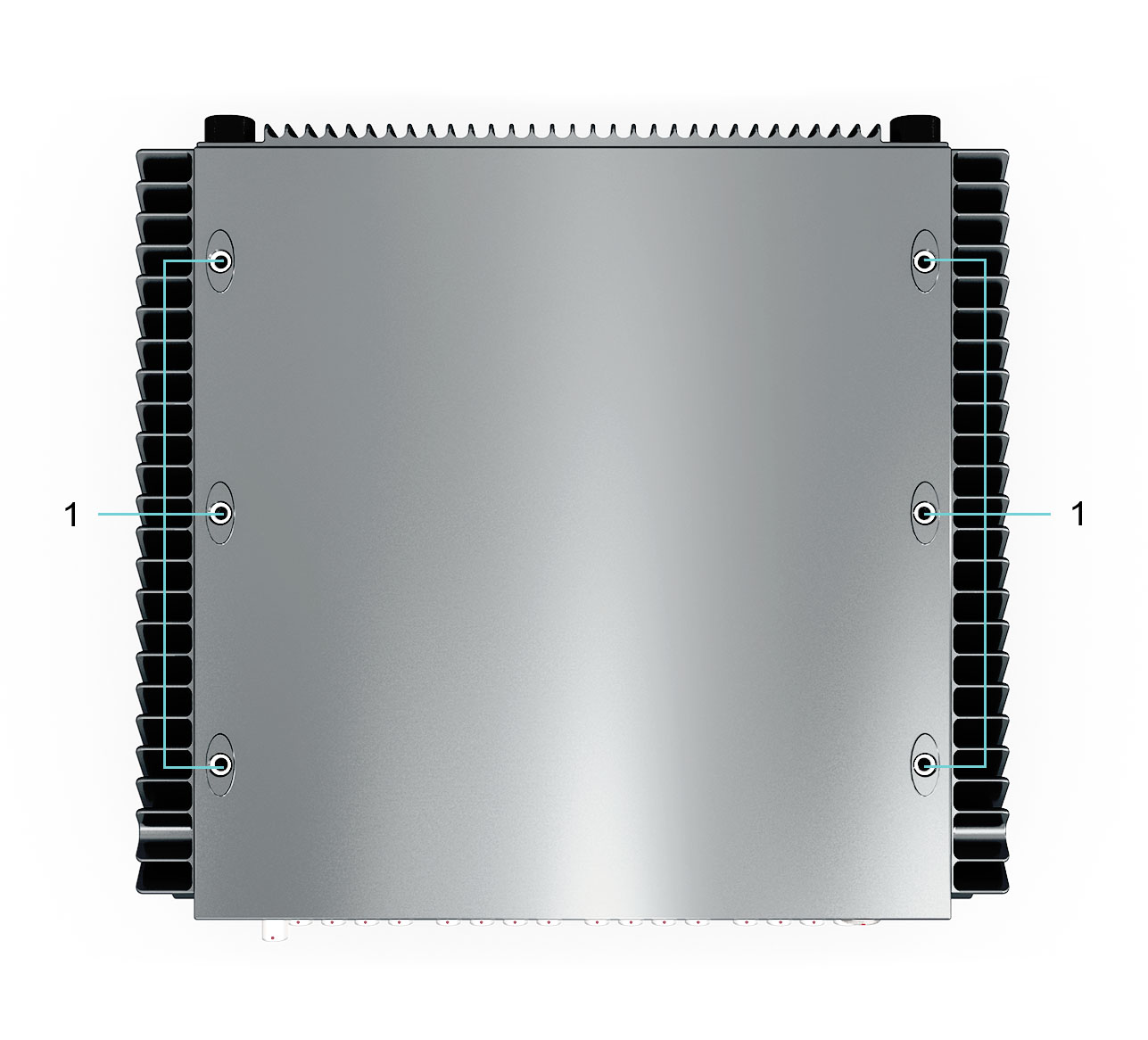

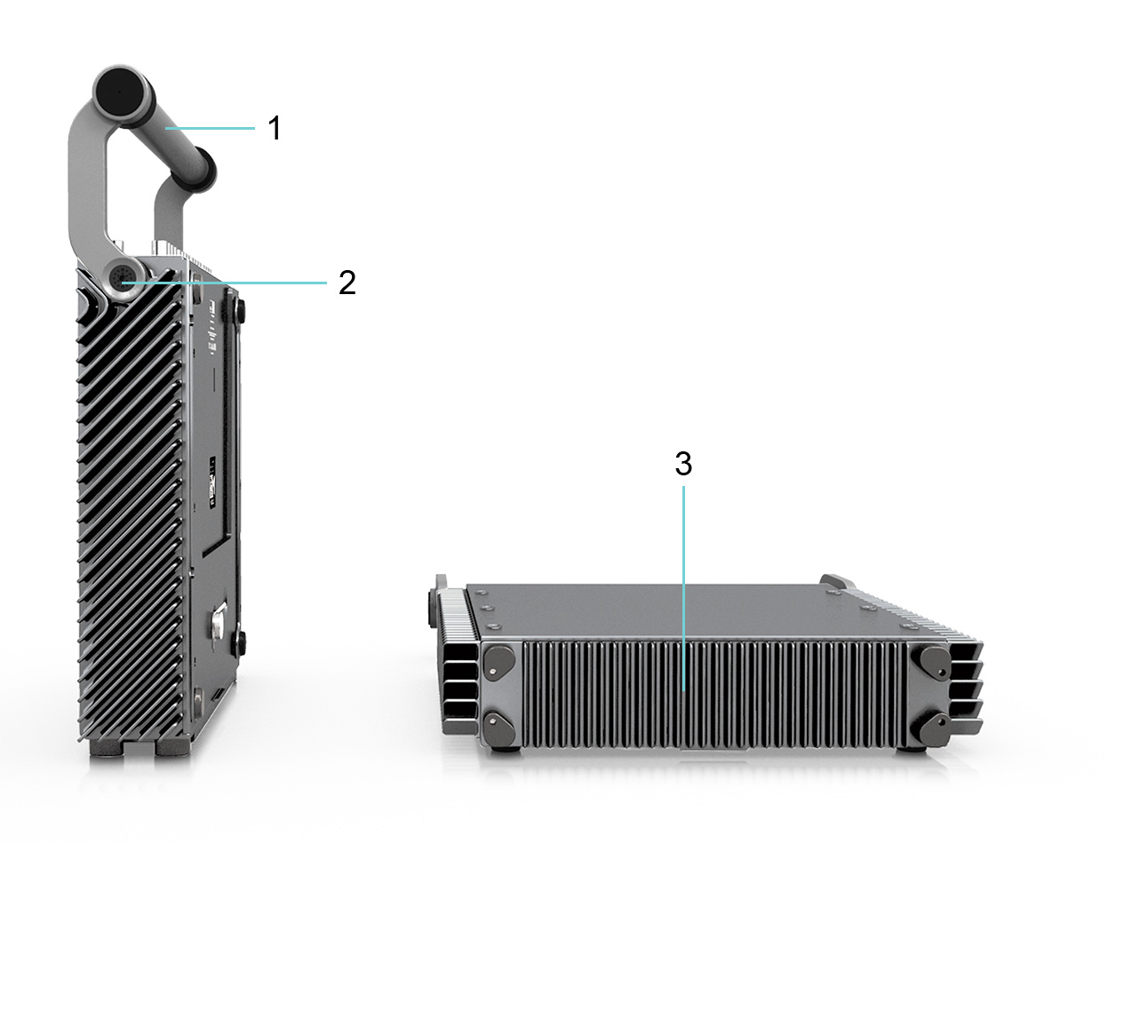

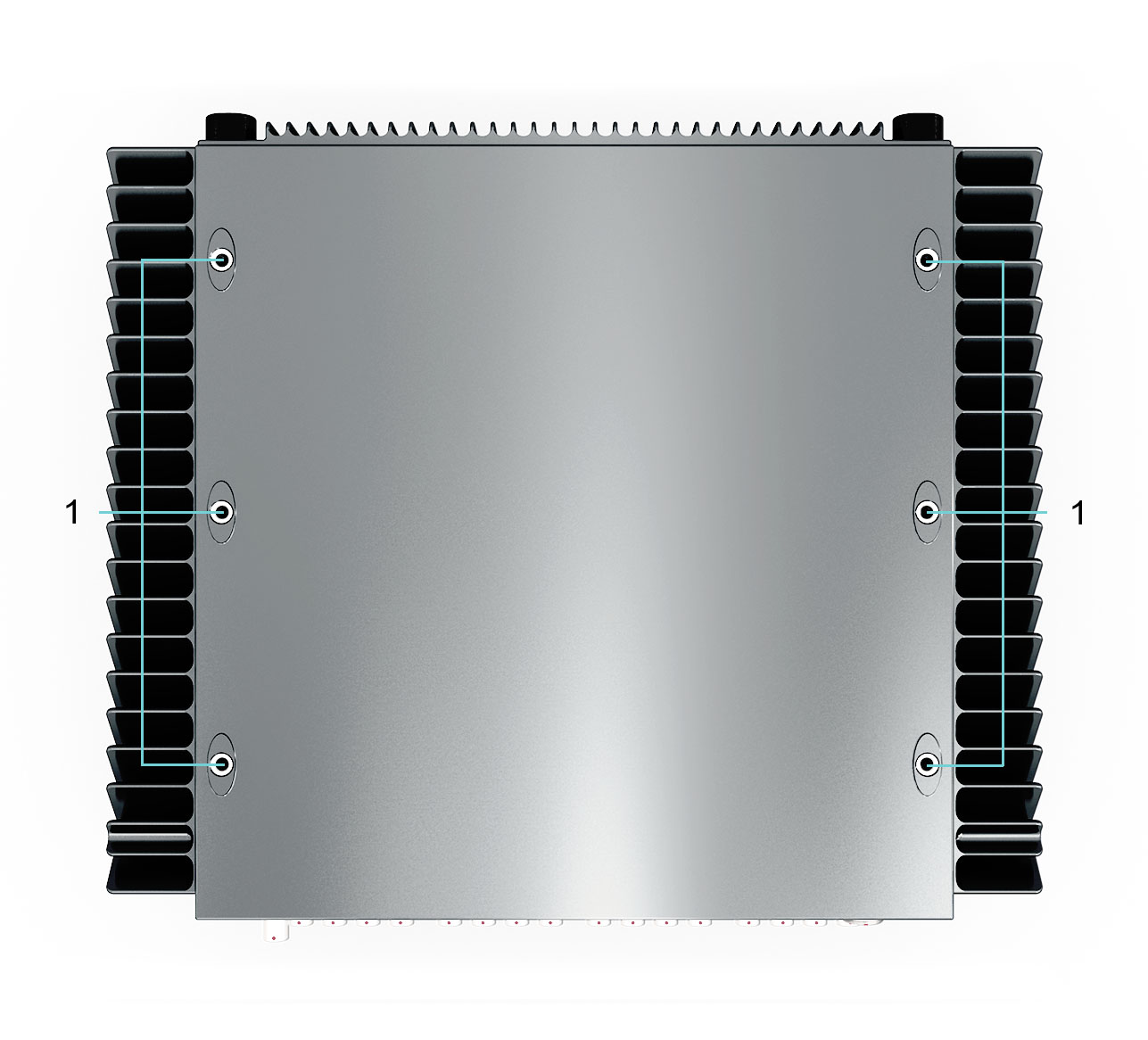

The following section provides the Top, Side and Bottom Views of the DECAQ 2-slot.

1. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

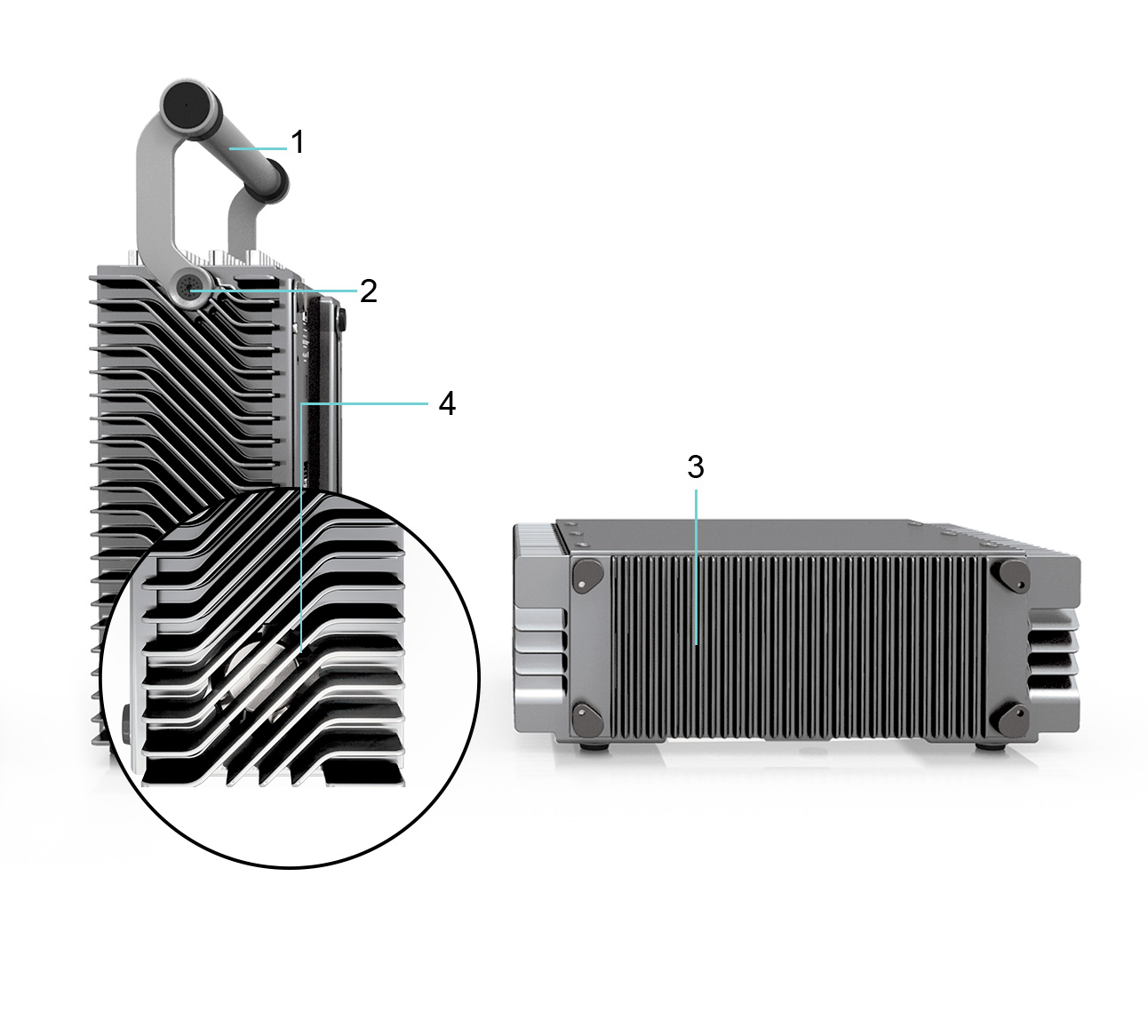

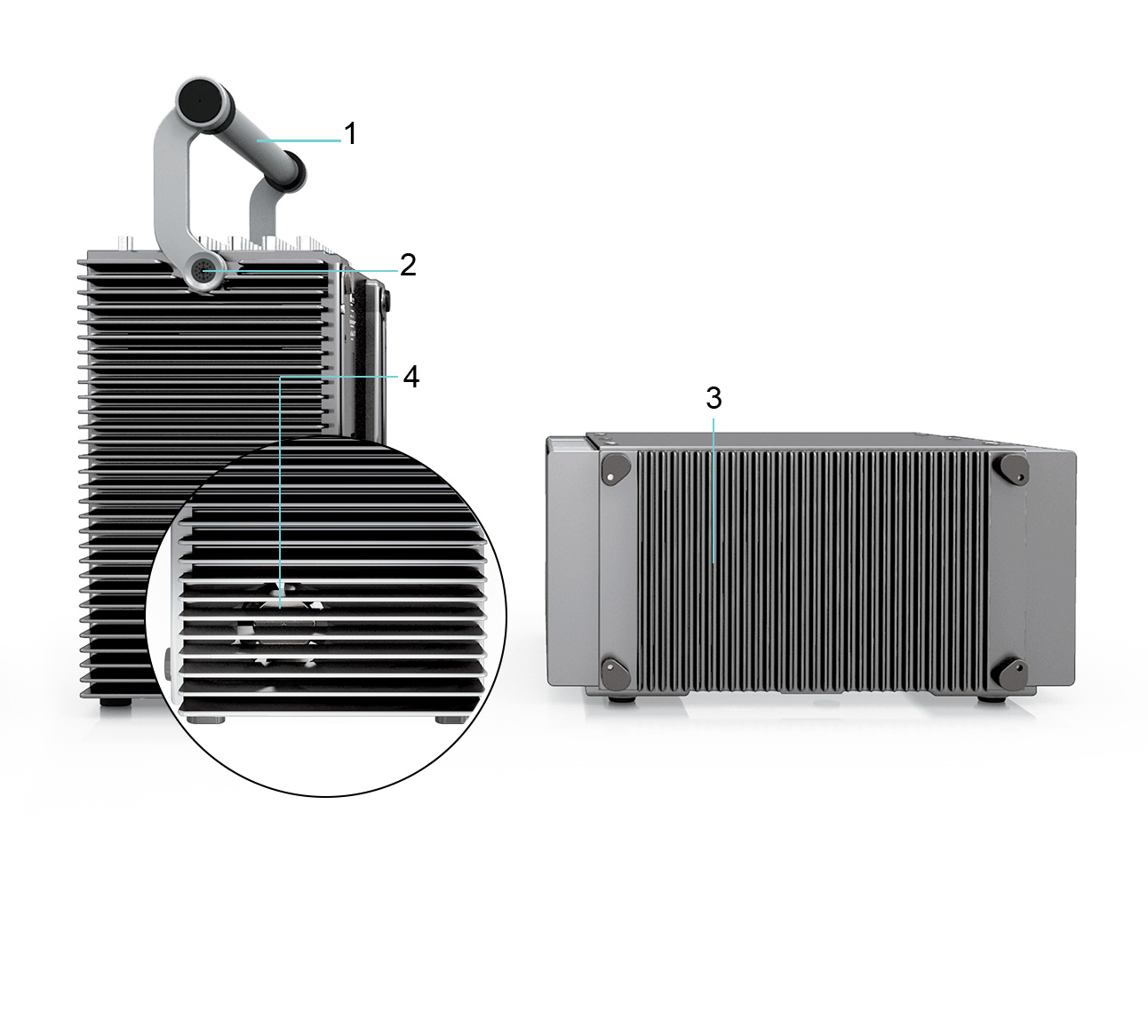

1. Handle For simplified handling, use the handle when carrying the chassis.

2. Handle Adjustment Button To adjust your handle, press down on the Handle Adjustment Button. Move the handle from 0° to 45°, 90°, 135° and finally 180°. Once the handle reaches any one of the four settings, it will lock into that position until the button is pressed in to adjust the handle again. Please ensure the Handle Adjustment Button is locked before picking up the system with the handle.

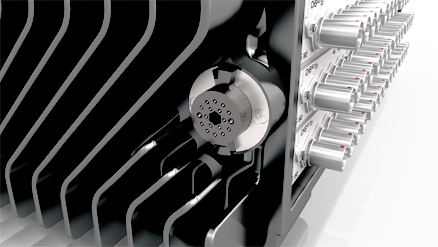

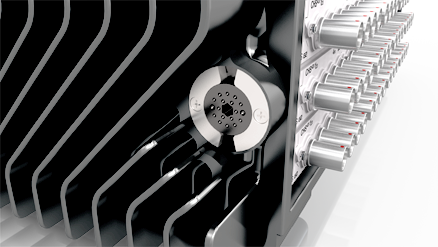

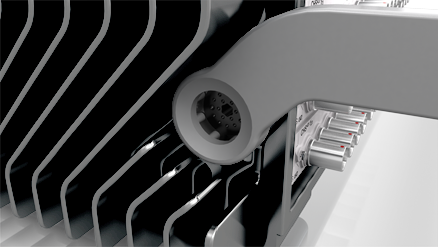

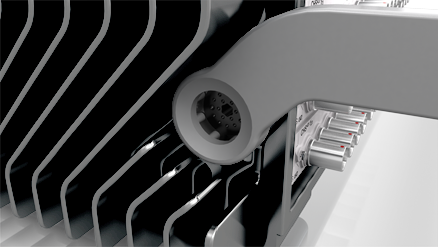

3. Fins Fins provide conduction cooling for the system chassis. Keep the chassis fins unobstructed while conducting a measurement. See Handling Guidelines for Effective Cooling for more information.

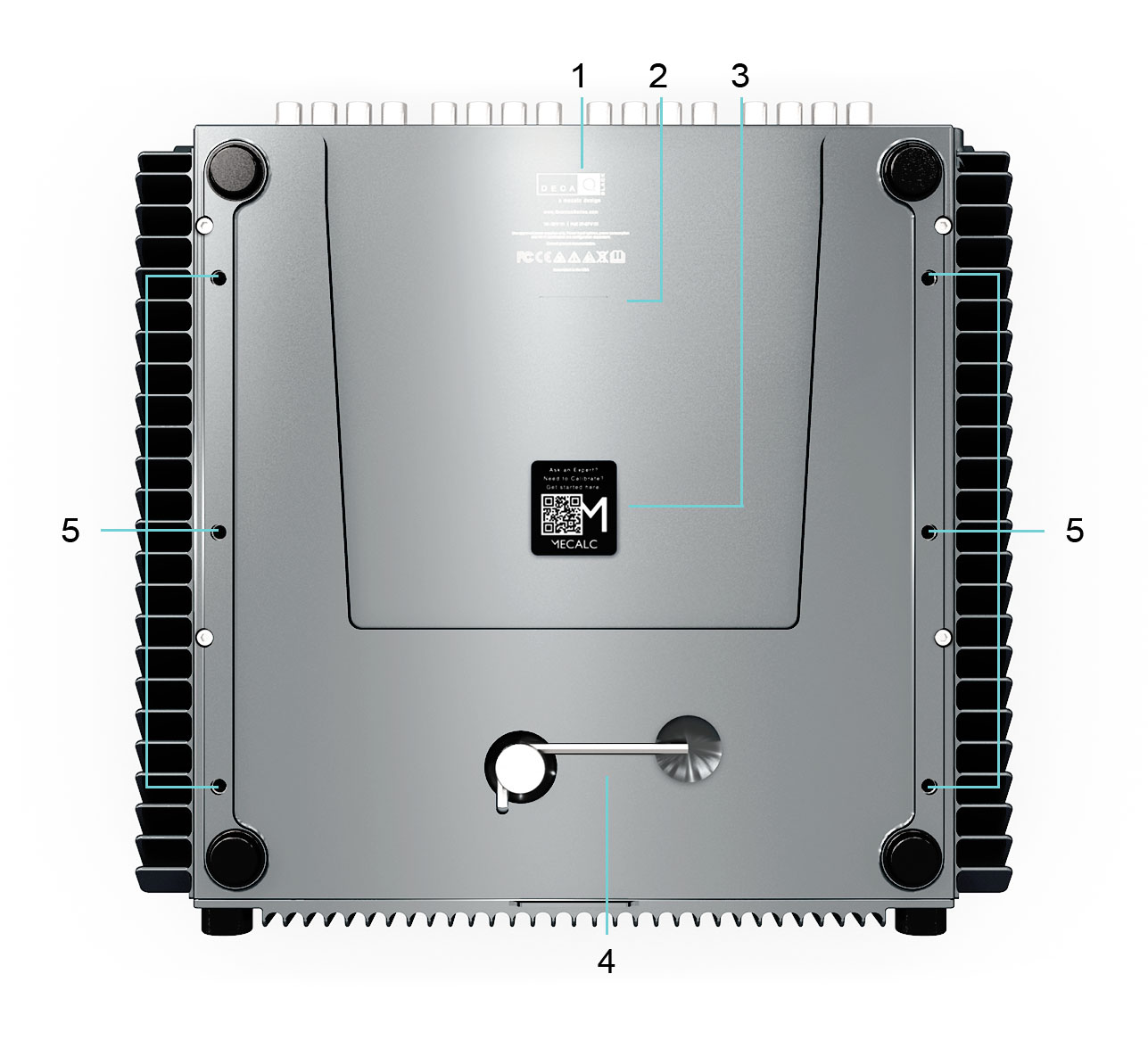

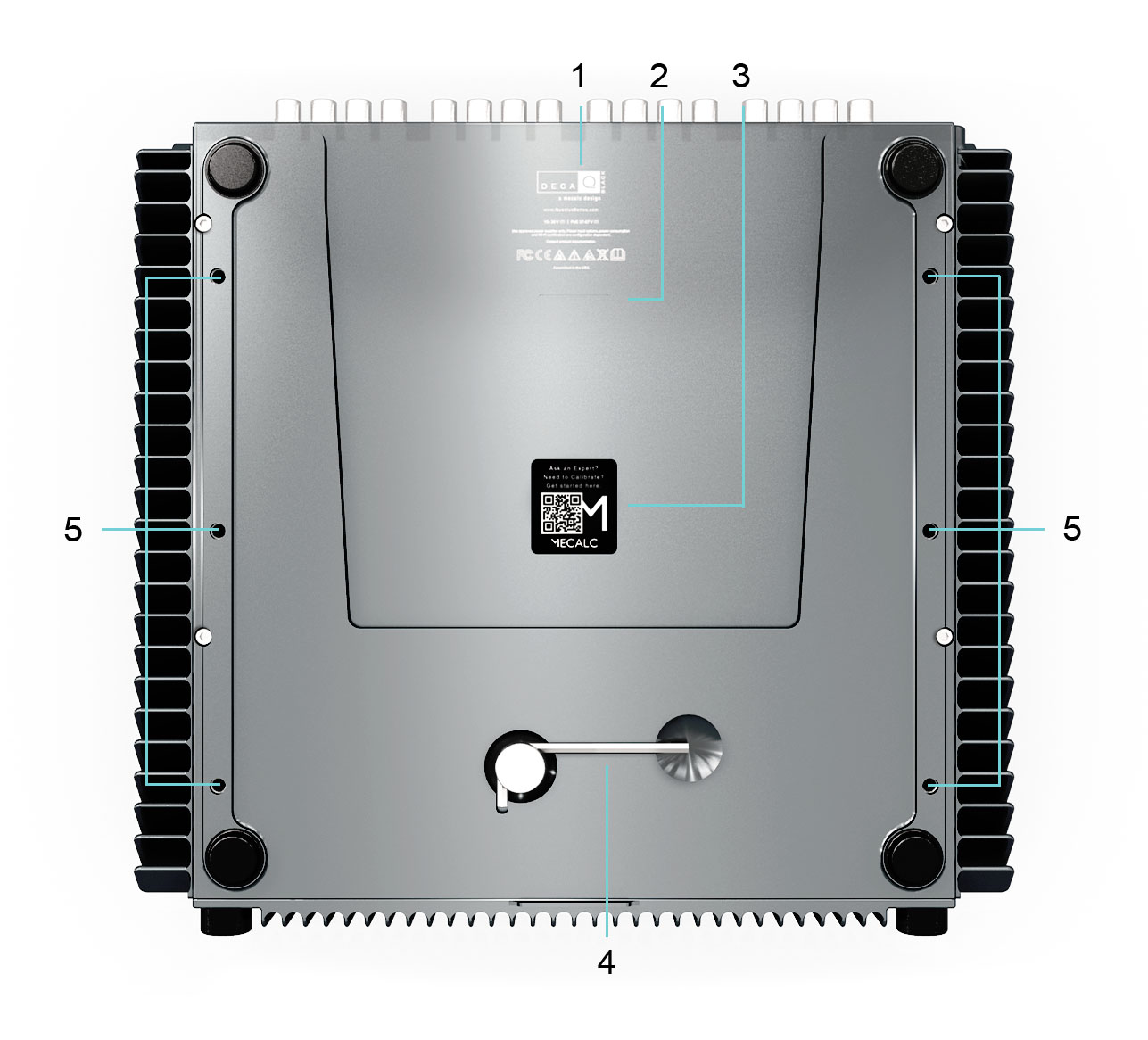

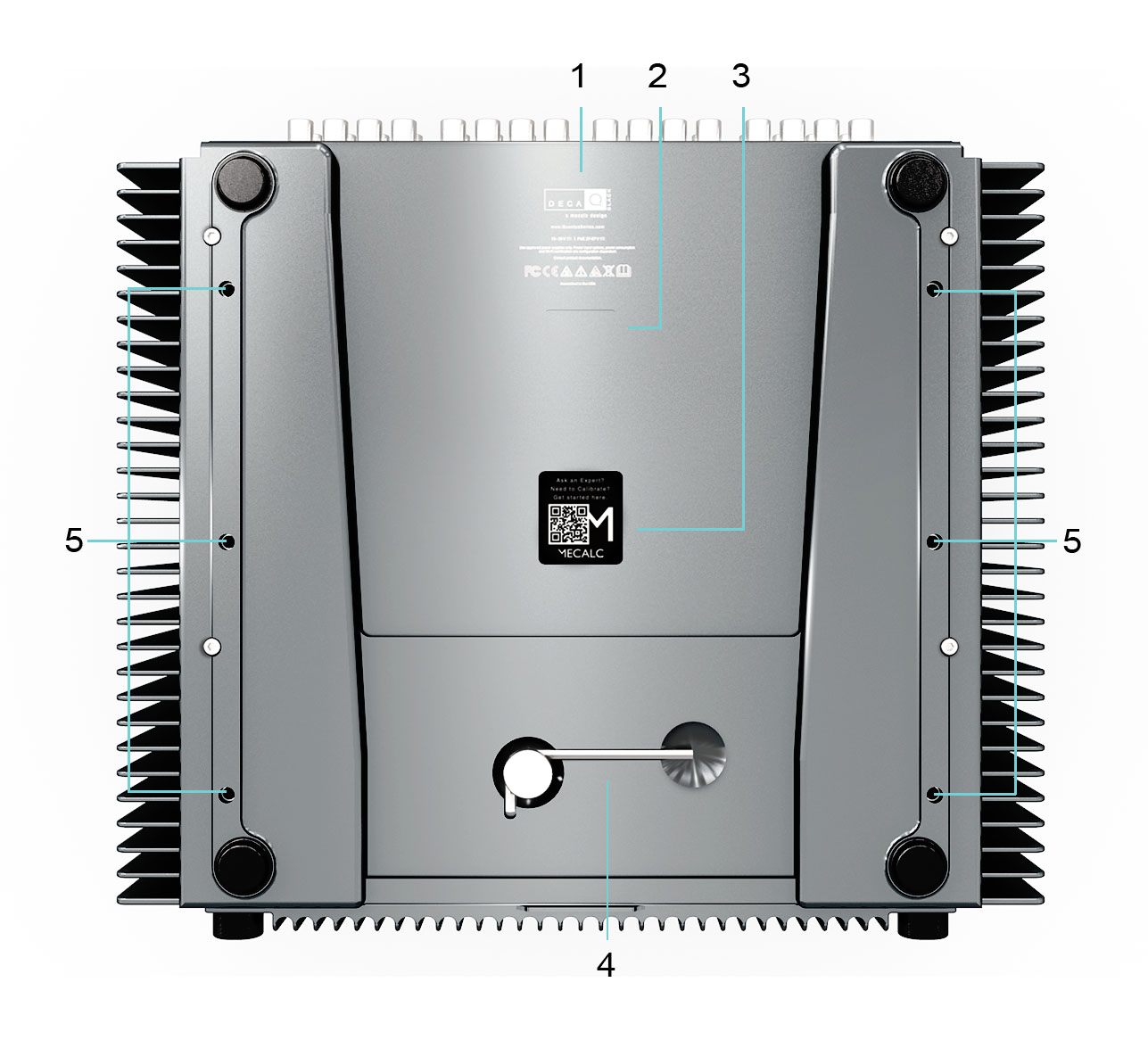

1. Product Identifier The Product Identifier includes certifications and warnings related to the use of the DECAQ.

2. Serial Number Label The Serial Number / Barcode Label of each DECAQ is found on its base. This identifier allows our Product Experts to access information specific to your device in order to provide valuable support services.

3. Mecalc or Partner Label The Mecalc or Partner Label provides a QR code that lets the User access support information such as User Guides.

4. HEX key The HEX key is used to gain access to the rear cover to insert/remove batteries.

5. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

The following section provides the Top, Side and Bottom Views of the DECAQ 3-slot.

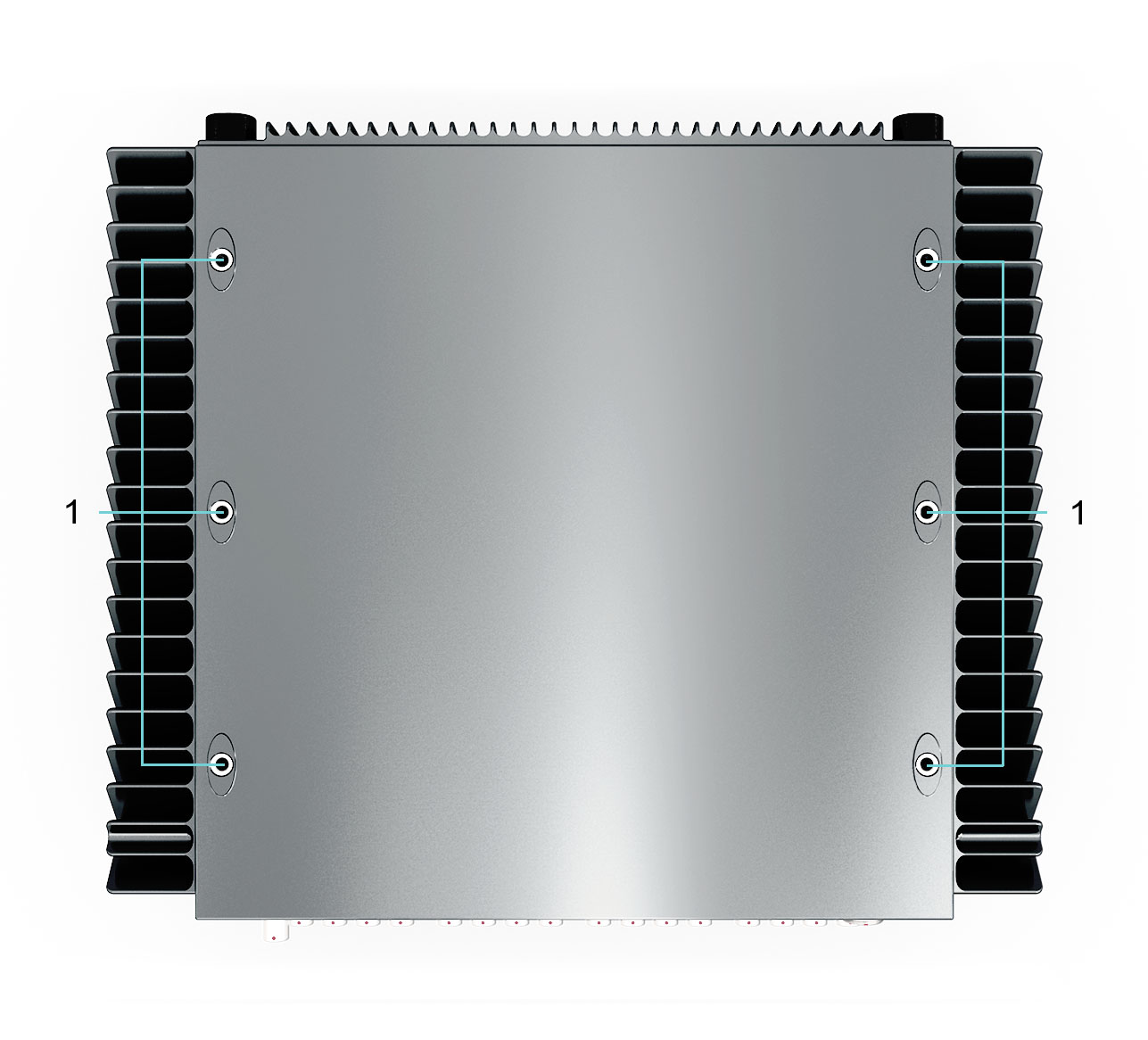

1. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

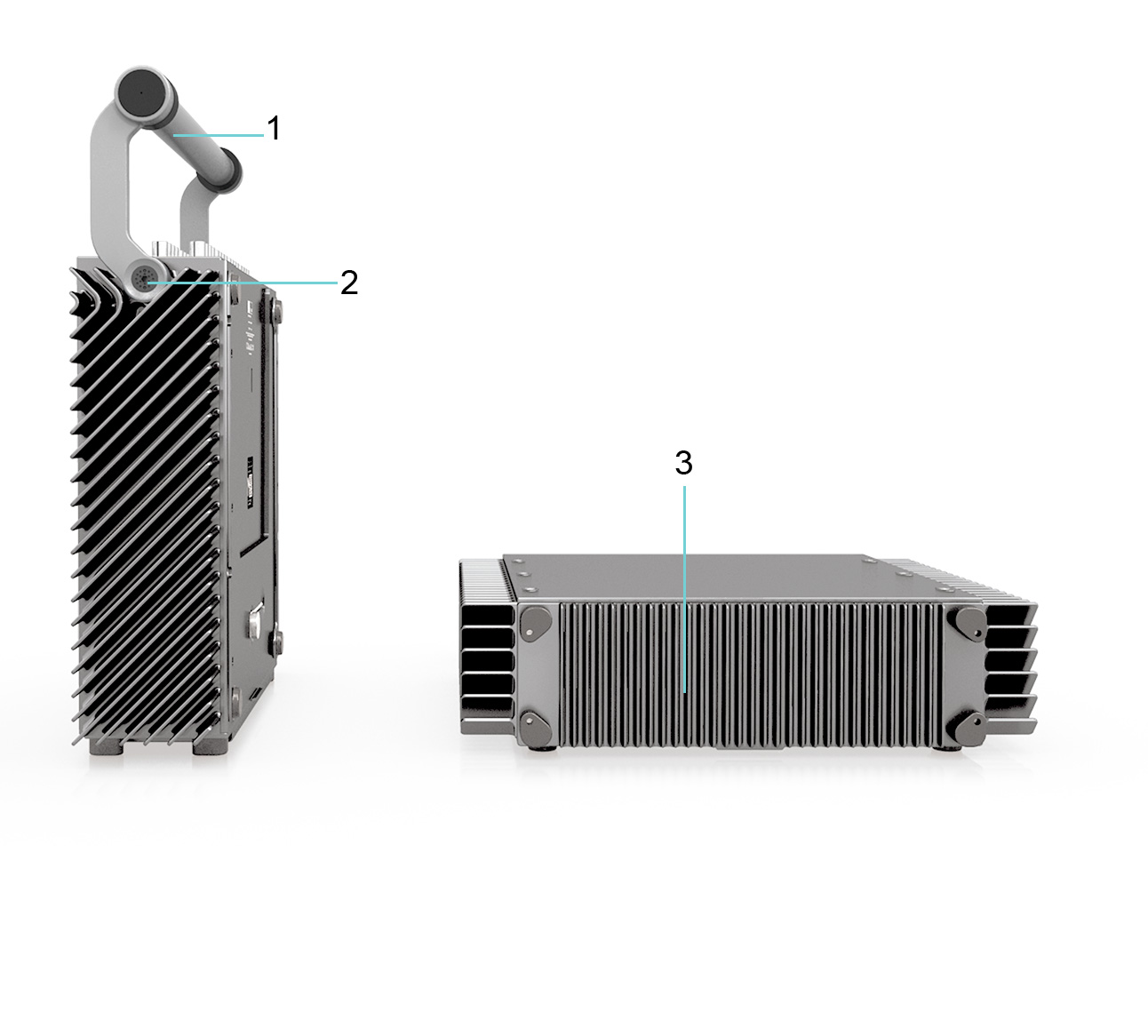

1. Handle For simplified handling, use the handle when carrying the chassis.

2. Handle Adjustment Button To adjust your handle, press down on the Handle Adjustment Button. Move the handle from 0° to 45°, 90°, 135° and finally 180°. Once the handle reaches any one of the four settings, it will lock into that position until the button is pressed in to adjust the handle again. Please ensure the Handle Adjustment Button is locked before picking up the system with the handle.

3. Fins Fins provide conduction cooling for the system chassis. Keep the chassis fins unobstructed while conducting a measurement. See Handling Guidelines for Effective Cooling for more information.

1. Product Identifier The Product Identifier includes certifications and warnings related to the use of the DECAQ.

2. Serial Number Label The Serial Number / Barcode Label of each DECAQ is found on its base. This identifier allows our Product Experts to access information specific to your device in order to provide valuable support services.

3. Mecalc or Partner Label The Mecalc or Partner Label provides a QR code that lets the User access support information such as User Guides.

4. HEX key The HEX key is used to gain access to the rear cover to insert / remove batteries.

5. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

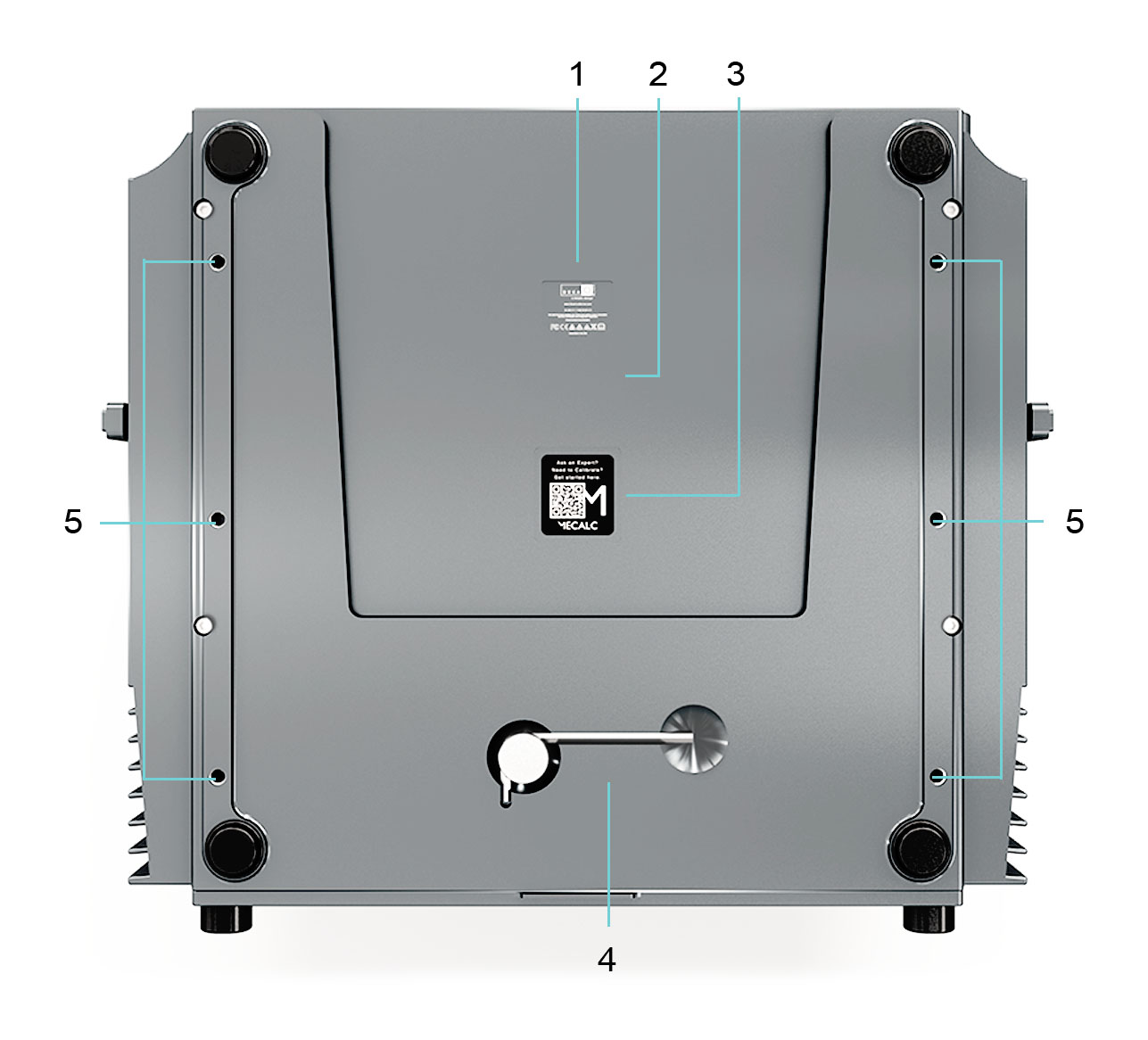

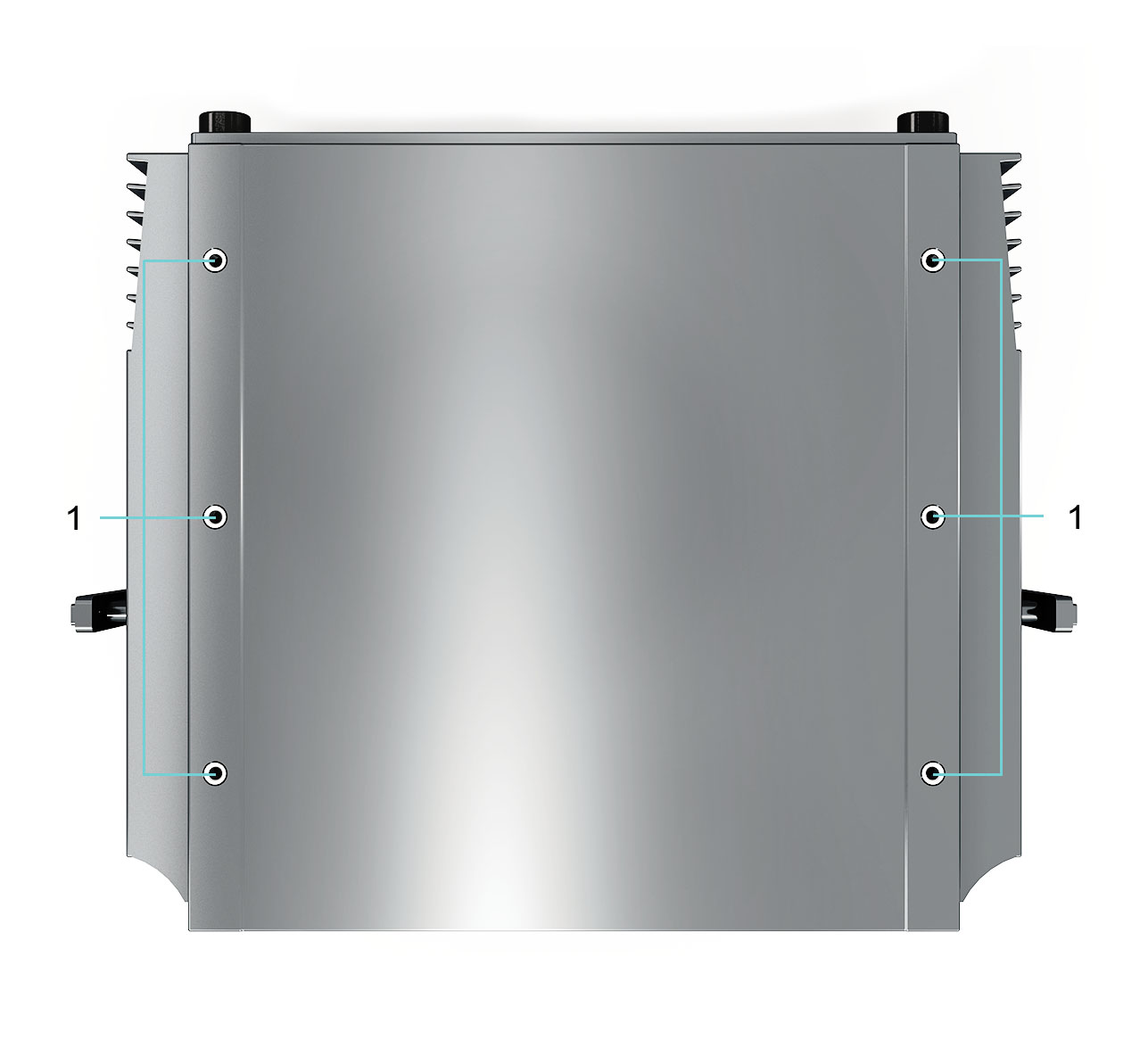

The following section provides the Top, Side and Bottom Views of the DECAQ 4-slot.

1. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

1. Handle For simplified handling, use the handle when carrying the chassis.

2. Handle Adjustment Button To adjust your handle, press down on the Handle Adjustment Button. Move the handle from 0° to 45°, 90°, 135° and finally 180°. Once the handle reaches any one of the four settings, it will lock into that position until the button is pressed in to adjust the handle again. Please ensure the Handle Adjustment Button is locked before picking up the system with the handle.

3. Fins Fins provide conduction cooling for the system chassis. Keep the chassis fins unobstructed while conducting a measurement. See Handling Guidelines for Effective Cooling for more information.

4. Fans Fans provide cooling for the system’s chassis. Keep the fan intake unobstructed while conducting a measurement. See Handling Guidelines for Effective Cooling for more information.

1. Product Identifier The Product Identifier includes certifications and warnings related to the use of the DECAQ.

2. Serial Number Label The Serial Number / Barcode Label of each DECAQ is found on its base. This identifier allows our Product Experts to access information specific to your device in order to provide valuable support services.

3. Mecalc or Partner Label The Mecalc or Partner Label provides a QR code that lets the User access support information such as User Guide.

4. HEX key The HEX key is used to gain access to the rear cover to insert / remove batteries.

5. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

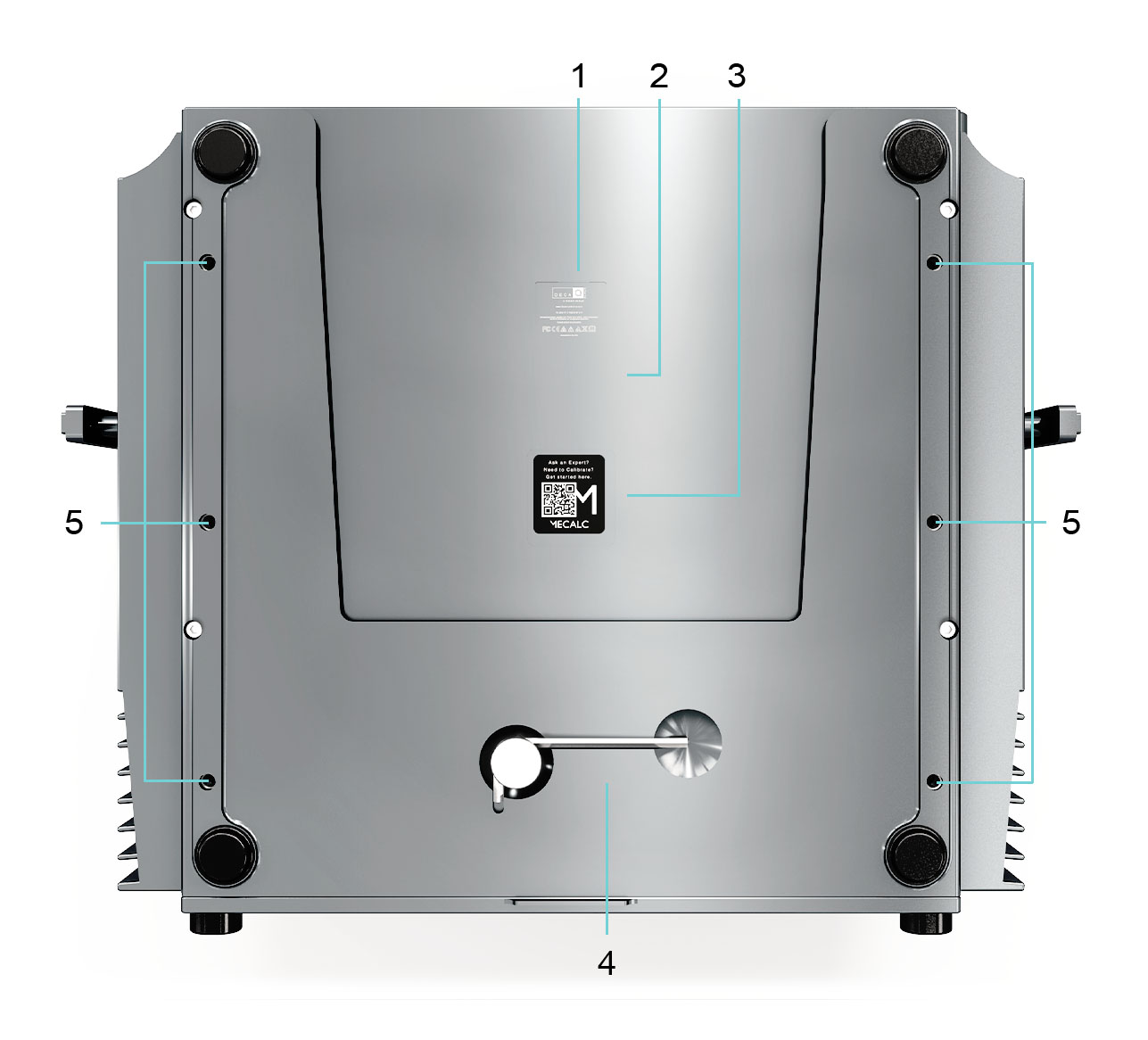

The following section provides the Top, Side and Bottom Views of the DECAQ 6-slot.

1. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

1. Handle For simplified handling, use the handle when carrying the chassis.

2. Handle Adjustment Button To adjust your handle, press down on the Handle Adjustment Button. Move the handle from 0° to 45°, 90°, 135° and finally 180°. Once the handle reaches any one of the four settings, it will lock into that position until the button is pressed in to adjust the handle again. Please ensure the Handle Adjustment Button is locked before picking up the system with the handle.

3. Fins Fins provide conduction cooling for the system chassis. Keep the chassis fins unobstructed while conducting a measurement. See Handling Guidelines for Effective Cooling for more information.

4. Fans Fans provide cooling for the system’s chassis. Keep the fan intake unobstructed while conducting a measurement. See Handling Guidelines for Effective Cooling for more information.

1. Product Identifier The Product Identifier includes certifications and warnings related to the use of the DECAQ.

2. Serial Number Label The Serial Number / Barcode Label of each DECAQ is found on its base. This identifier allows our Product Experts to access information specific to your device in order to provide valuable support services.

3. Mecalc or Partner Label The Mecalc or Partner Label provides a QR code that lets the User access support information such as User Guide.

4. HEX key The HEX key is used to gain access to the rear cover to insert / remove batteries.

5. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

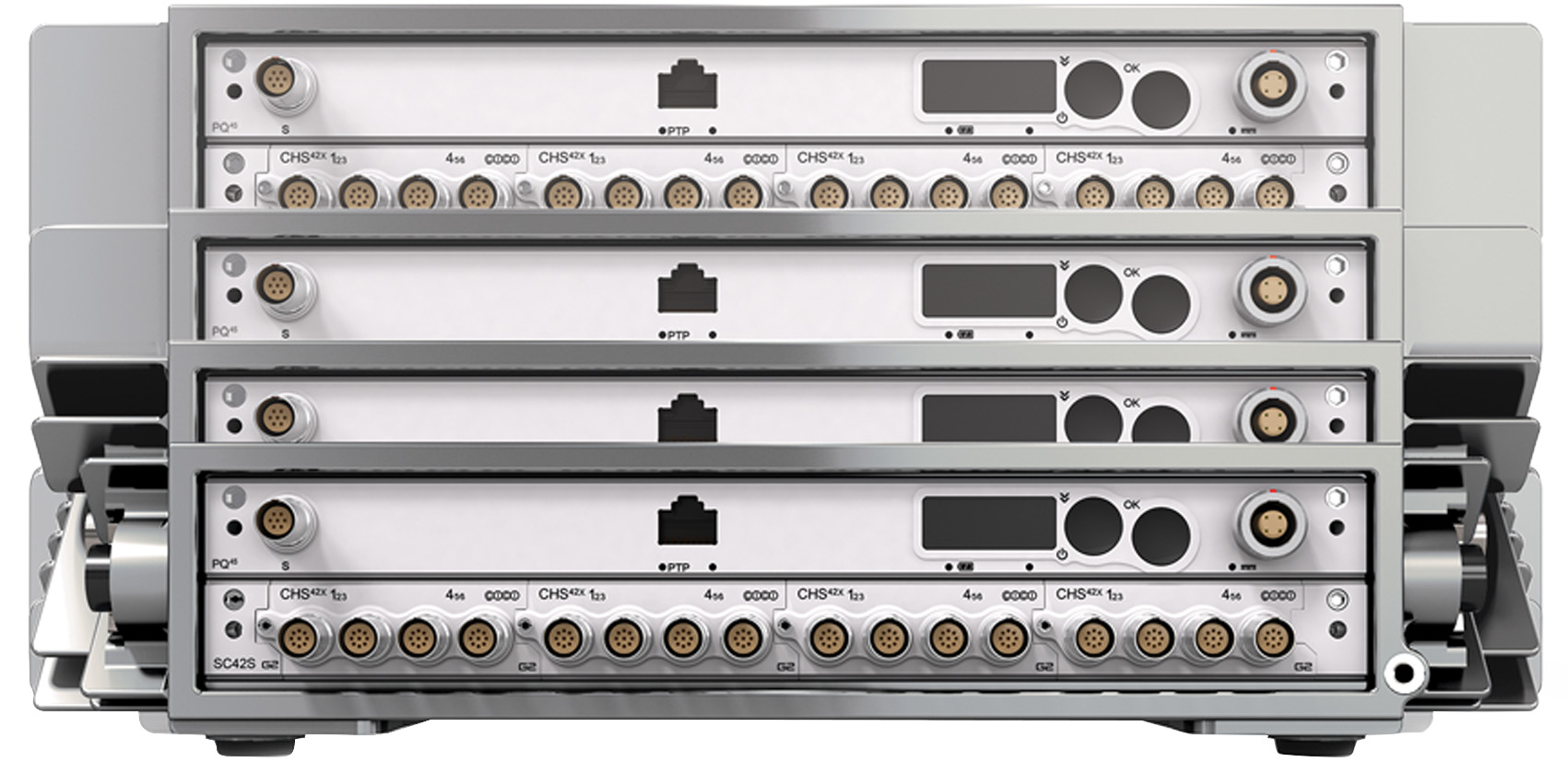

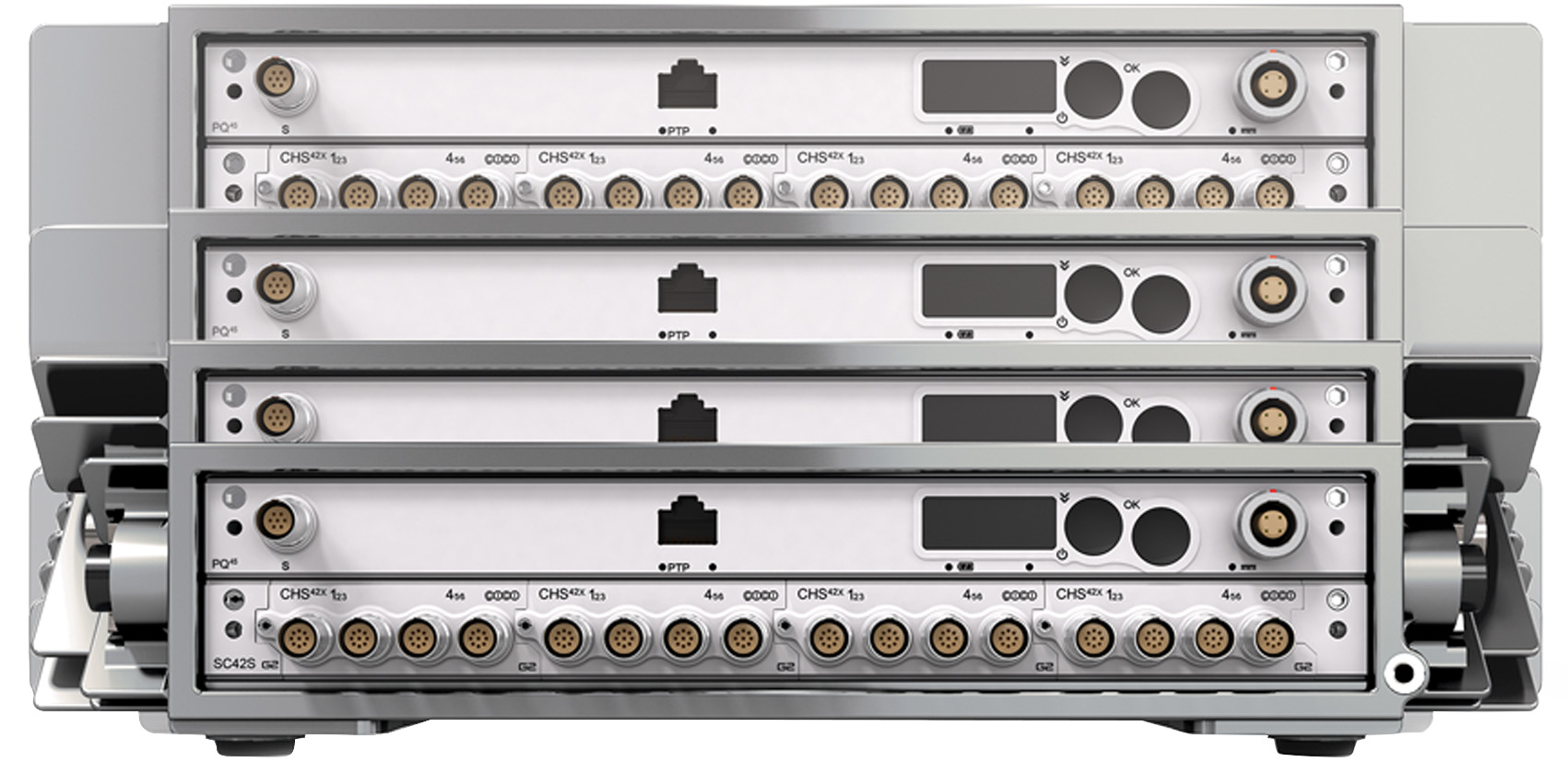

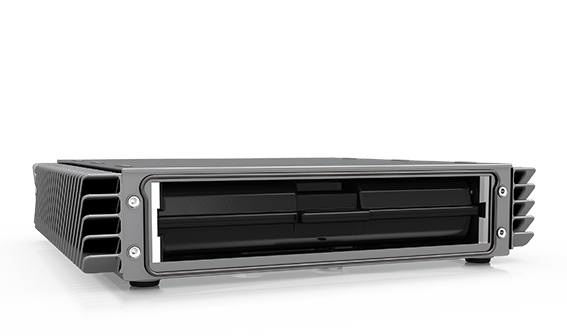

The DECAQ L chassis has been designed to fit into a 19” rack for stationary use in a laboratory. The DECAQ L chassis has improved airflow with air being blown through vents at both sides. There are no fins on the sides or the rear of the DECAQ L chassis.

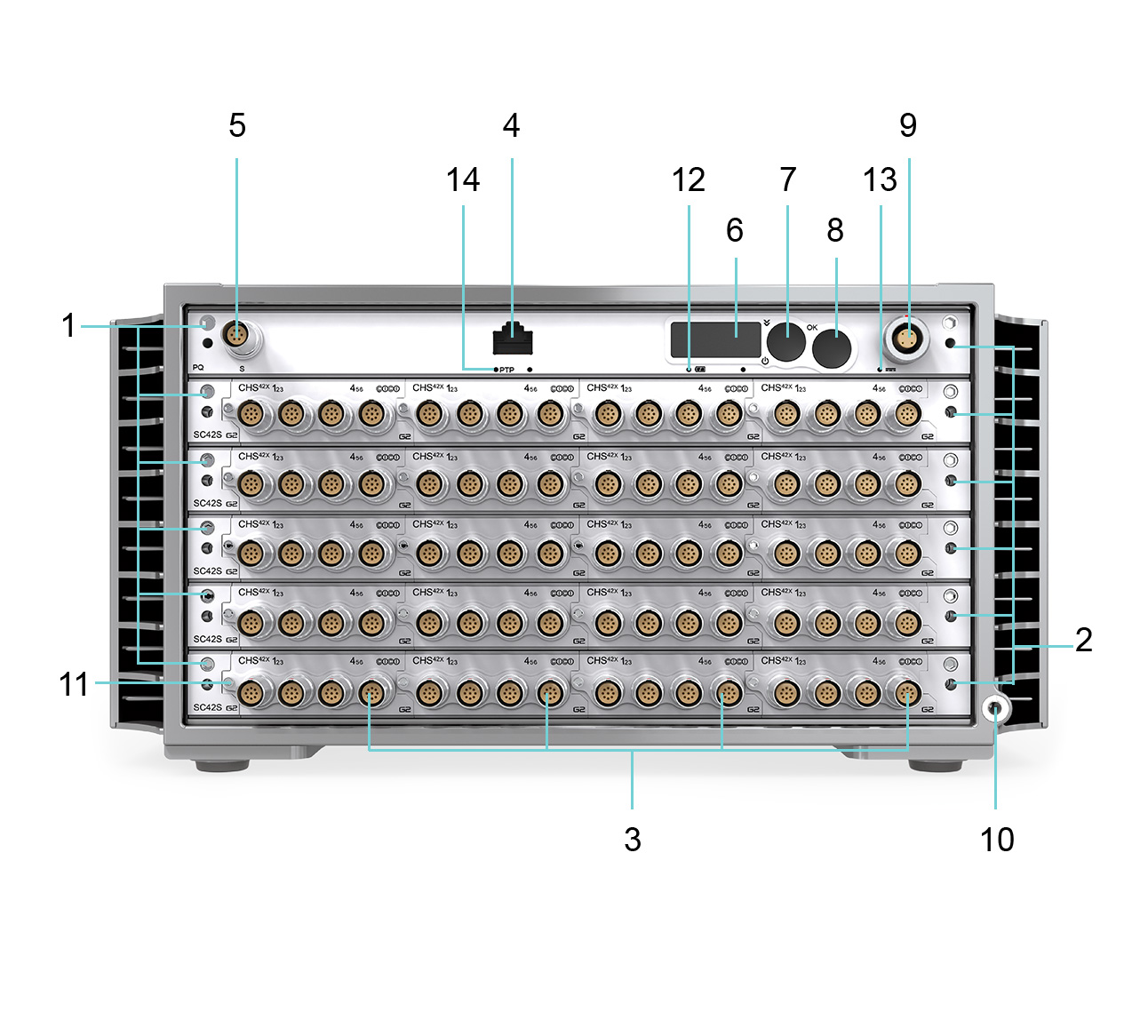

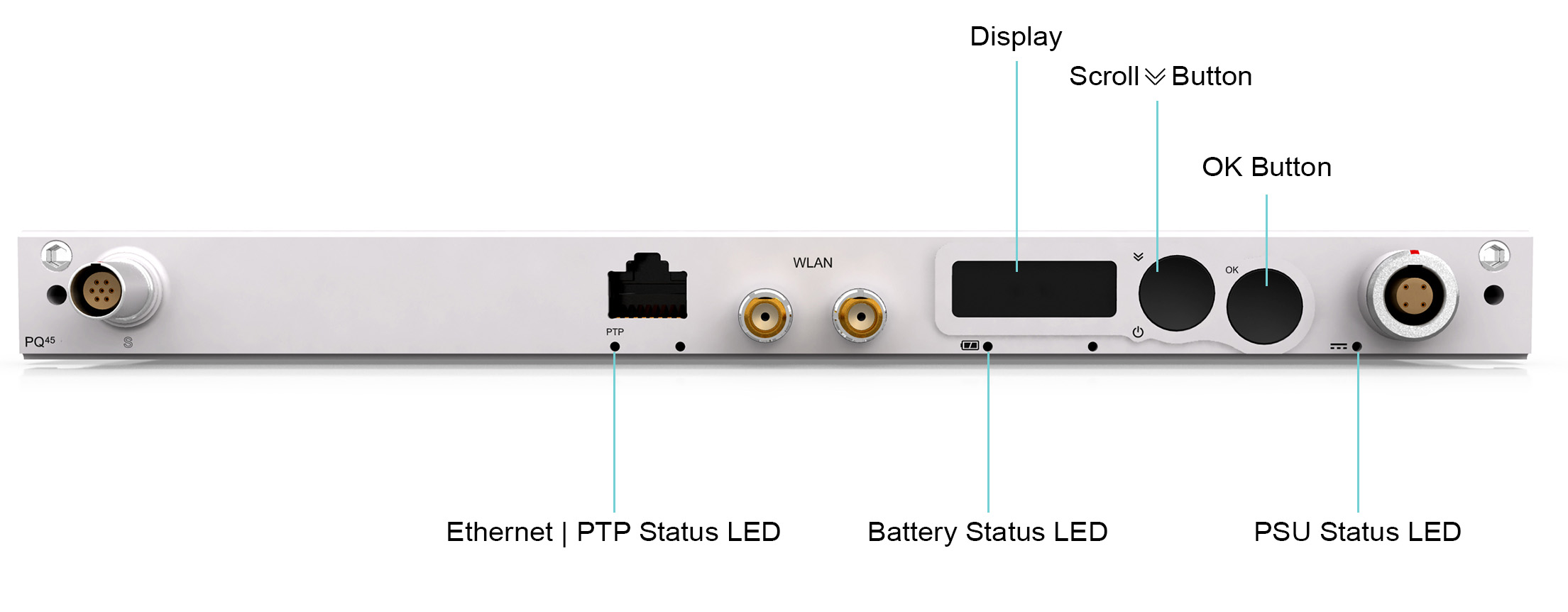

This section highlights front view features common to all L systems.

1. Extraction Jacking Screw To remove the board from the chassis during system maintenance, tighten the extraction jacking screw until the board ejects.

2. Portal for Thermal Expanders Ensure the thermal expanders have been properly fastened before conducting measurements. See Handling Guidelines for Effective Cooling for more information.

3. QModule slots Featured QModule: Slot 2 CHS42X:6 Channel Charge or ICP®/IPE and Voltage Input Amplifier See Measure: Signal Conditioning for more information.

4. Ethernet (Ethernet / PTP) Ethernet 1000BASE-T PTP (Precision Time Protocol) IEEE 1588-2008 PTP synchronization over Ethernet. See Synchronization for more information.

5. S-Port Connect to the ATTOQs via the S-Port.

6. User Interface Display Receive system information and execute commands via the User Interface. See Navigating the DECAQ’s User Interface Display for more information.

7. User Interface Scroll Button

( )

)

Use the Scroll Button to switch on the DECAQ L and scroll through the User Interface menu options. See Navigating the DECAQ’s User Interface Display for more information.

8. User Interface OK Button Confirm User Interface menu option selections using the OK Button. See Navigating the DECAQ’s User Interface Display for more information.

9. Power LEMO® Power the DECAQ L with an external power source via the Power LEMO®. See Power for more information.

10. Earth Terminal Beware of ground loops as the system is earthed via the Mean Well power supply. Consider connecting the Earth Terminal to the building safety earth if there is any risk of electrical shock in the testing environment. It can be used to provide a ground reference for analog signal measurements, if appropriate settings are applied to the relevant QModule channels. It can also be used in some cases to decrease noise on analog signals.

11. QModule Jacking Screw Insert and remove QModules using a Jacking Screw. See Inserting and Removing QModules for more information.

12. Battery Status LED Provides information about the internal battery to the User.

13. Power Supply Status LED Provides information about the power supply to the User.

14. Ethernet / PTP Status LED Synchronize DECAQ systems with PTP (Precision Time Protocol) See Synchronization for more information.

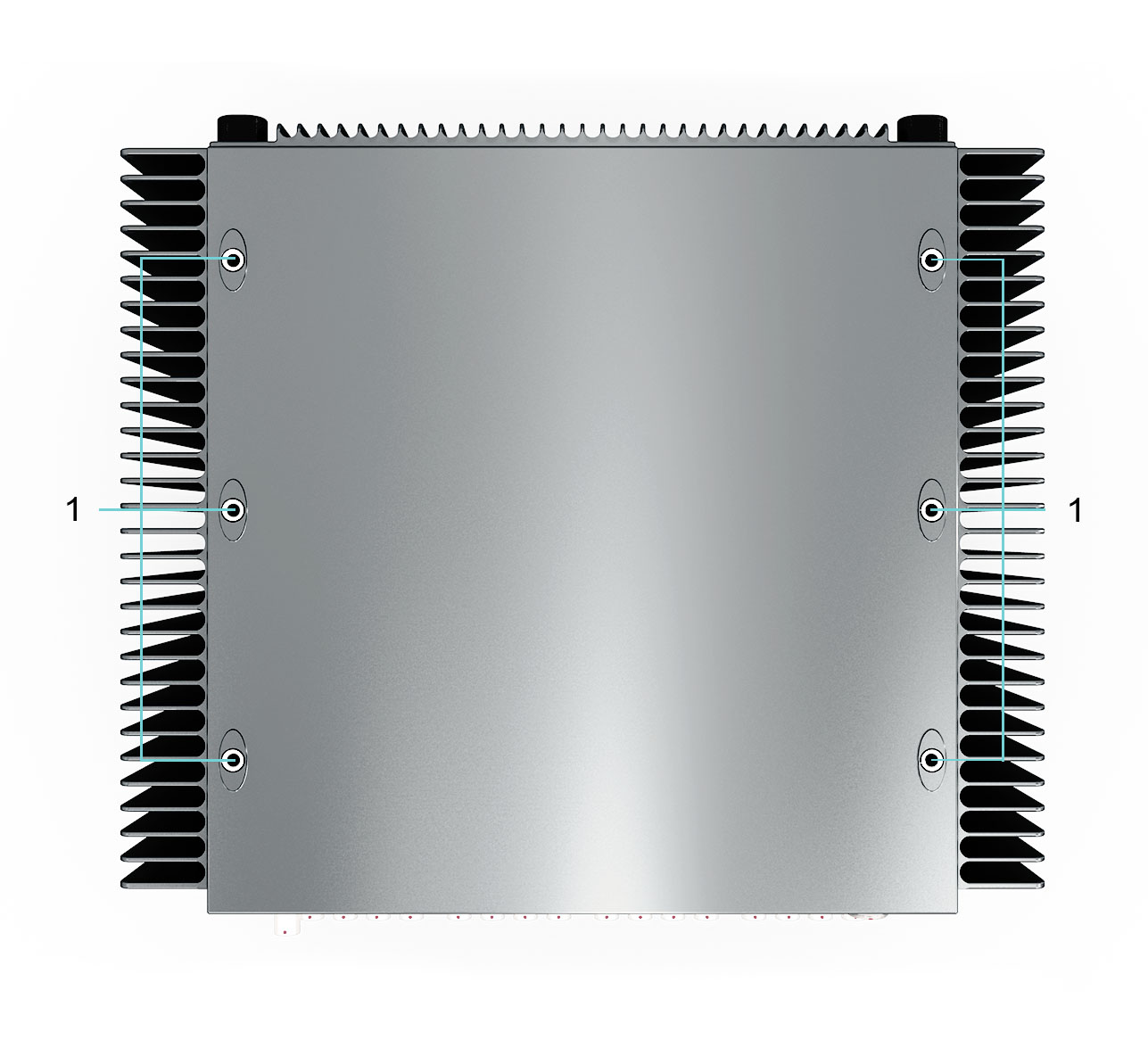

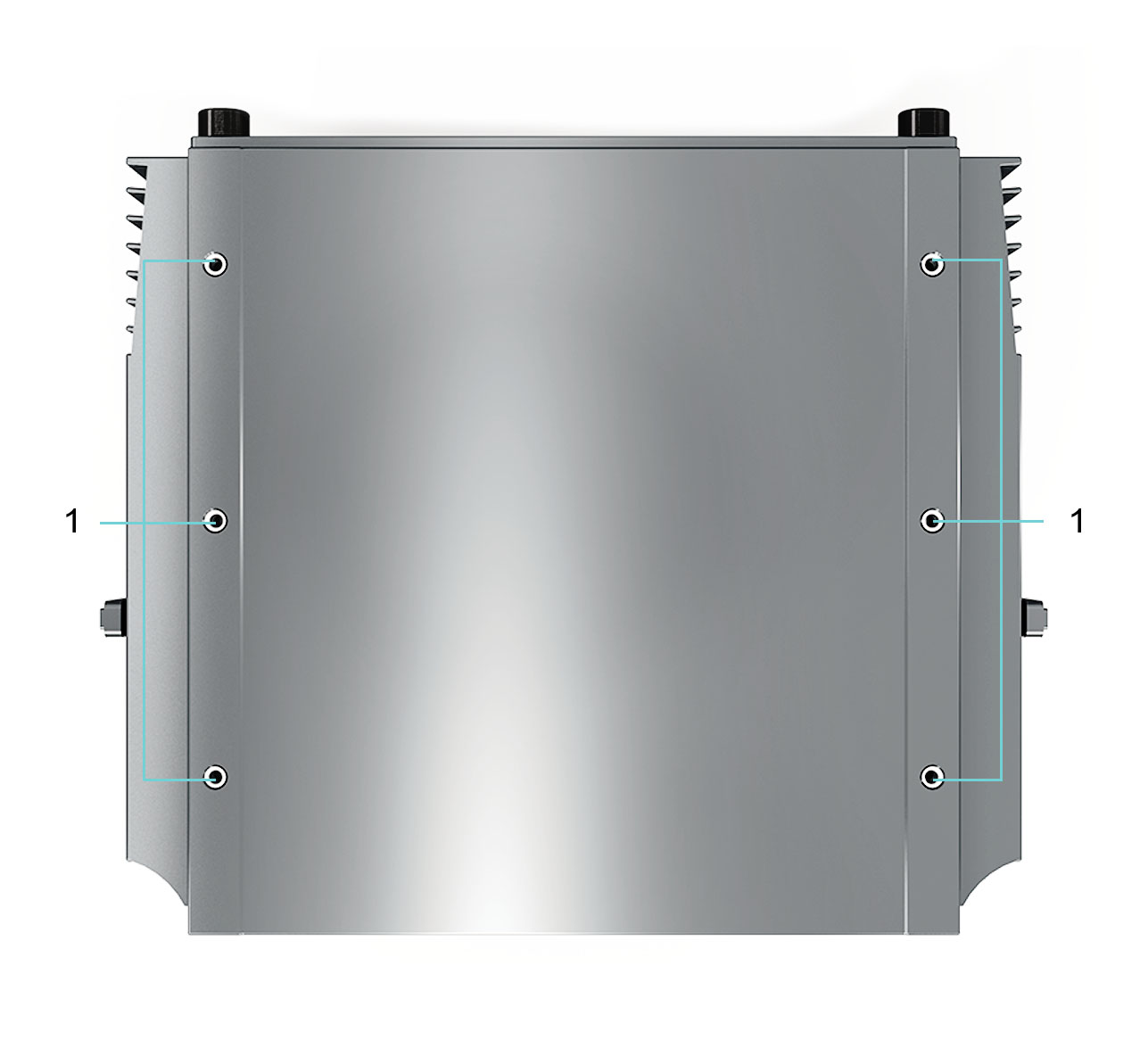

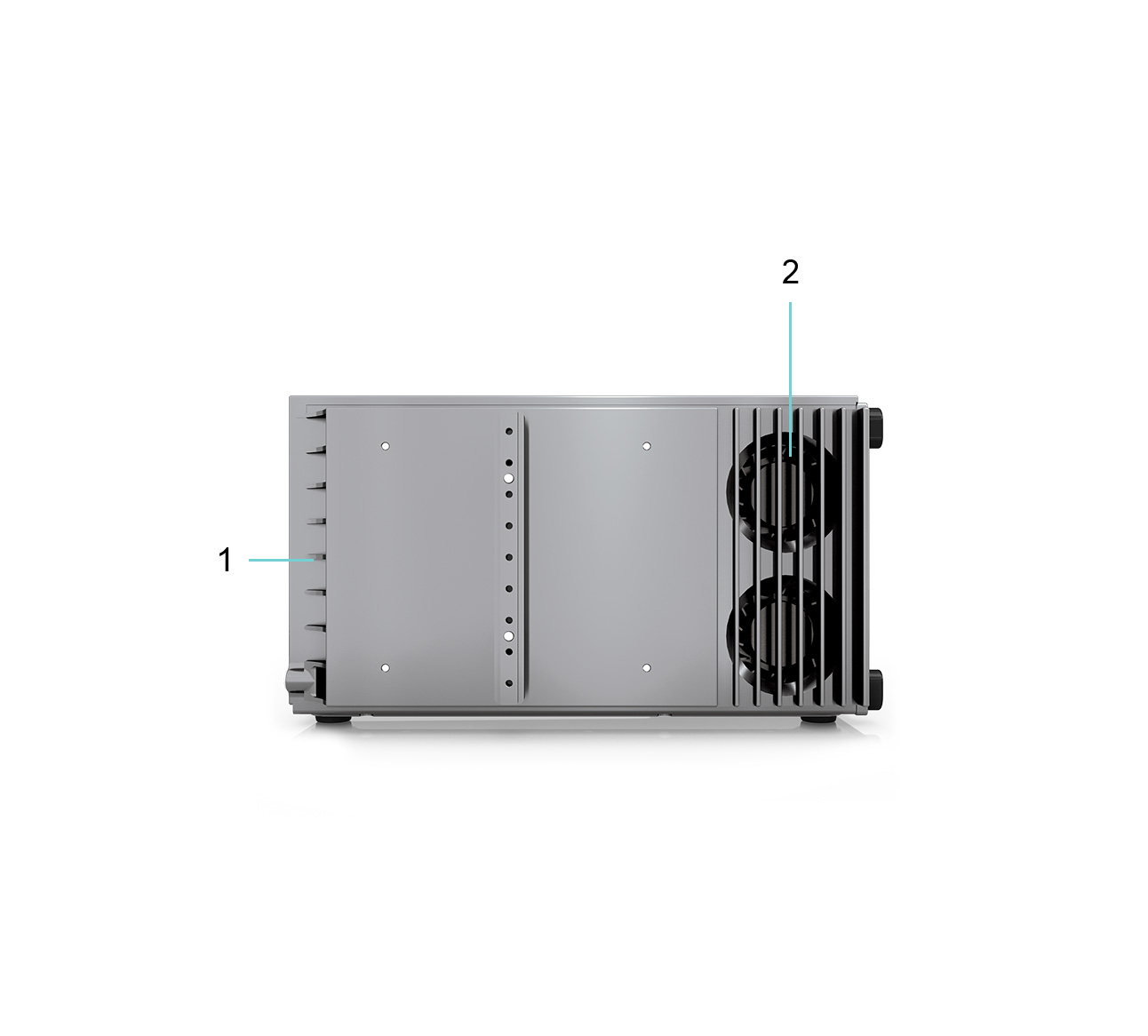

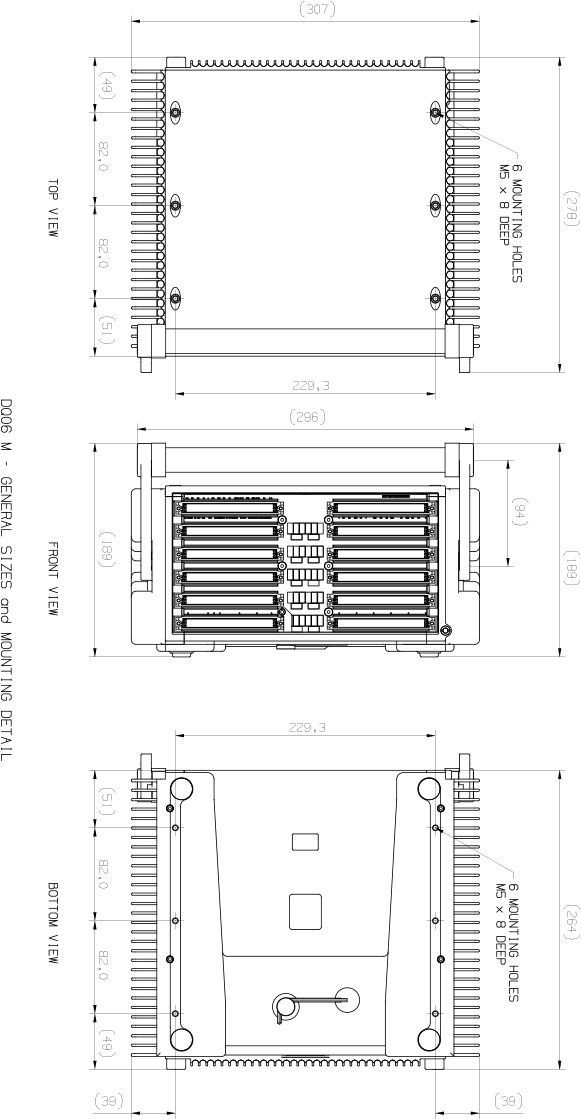

The following section provides the Top, Side and Bottom Views of the DECAQ L 4-slot.

1. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

1. Vents Vents provide conduction cooling for the system chassis. Keep the chassis vents unobstructed while conducting a measurement. See Handling Guidelines for Effective Cooling for more information.

2. Fans Fans provide cooling for the system’s chassis. Keep the fan intake unobstructed while conducting a measurement. See Handling Guidelines for Effective Cooling for more information.

1. Product Identifier The Product Identifier includes certifications and warnings related to the use of the DECAQ L.

2. Serial Number Label The Serial Number / Barcode Label of each DECAQ L is found on its base. This identifier allows our Product Experts to access information specific to your device in order to provide valuable support services.

3. Mecalc or Partner Label The Mecalc or Partner Label provides a QR code that lets the User access support information such as User Guide.

4. HEX key The HEX key is used to gain access to insert/remove batteries.

5. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

The following section provides the Top, Side and Bottom Views of the DECAQ 6-slot.

1. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

1. Vents Vents provide conduction cooling for the system chassis. Keep the chassis vents unobstructed while conducting a measurement. See Handling Guidelines for Effective Cooling for more information.

2. Fans Fans provide cooling for the system’s chassis. Keep the fan intake unobstructed while conducting a measurement. See Handling Guidelines for Effective Cooling for more information.

1. Product Identifier The Product Identifier includes certifications and warnings related to the use of the DECAQ.

2. Serial Number Label The Serial Number / Barcode Label of each DECAQ is found on its base. This identifier allows our Product Experts to access information specific to your device in order to provide valuable support services.

3. Mecalc or Partner Label The Mecalc or Partner Label provides a QR code that lets the User access support information such as User Guide.

4. HEX key The HEX key is used to gain access to insert/remove batteries.

5. Fastening Inserts Fasten your chassis onto a surface using the fastening inserts.

The DECAQ complies with EMC directives.

When connecting cables, sensors or third-party devices to the DECAQ, electromagnetic noise could be introduced into the measurement.

Recommendations for good measurement practice include:

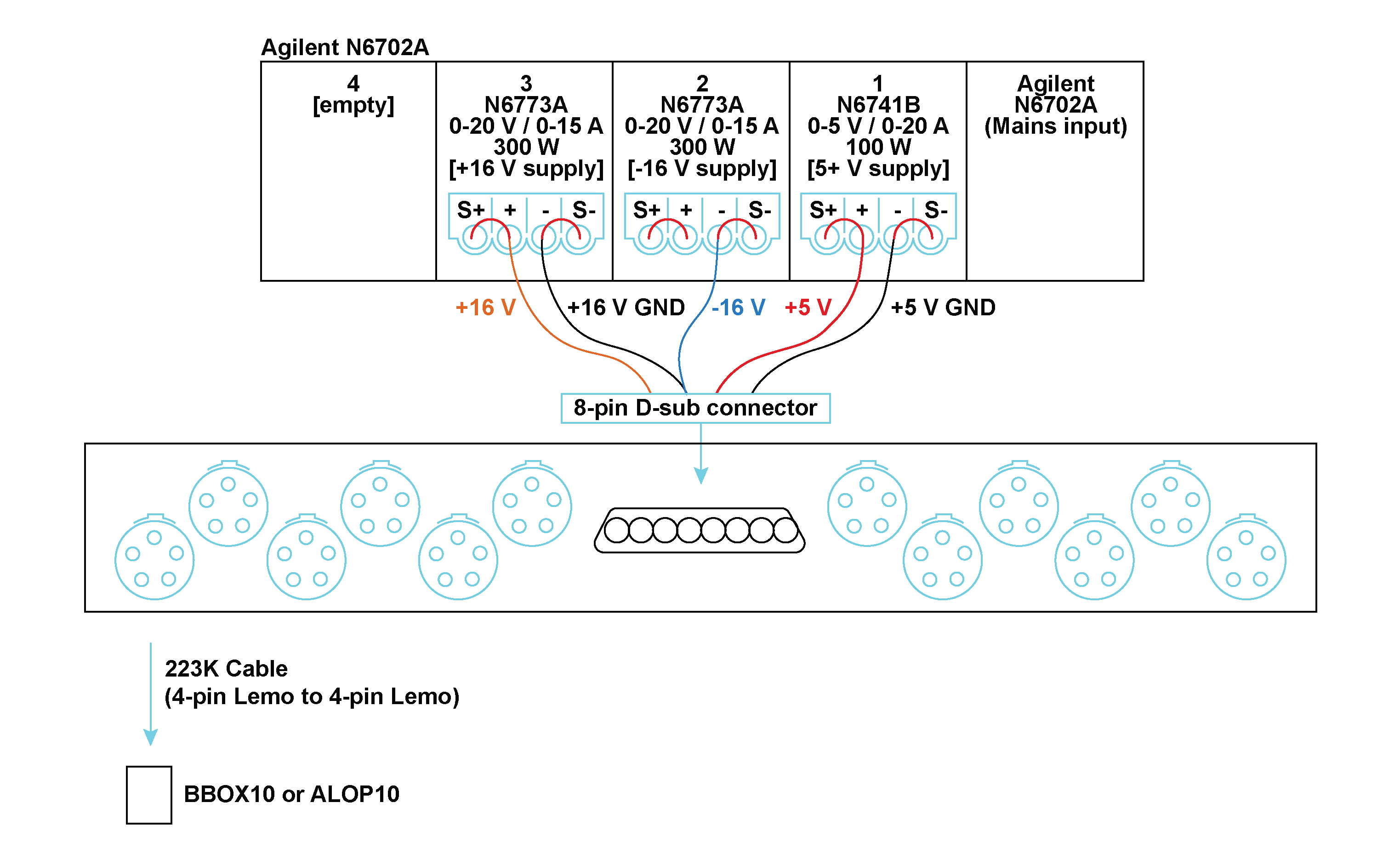

The DECAQ systems use customized power cables to ensure they operate at their optimum level. Using a third-party cable is highly discouraged, as this may damage your system. Contact your supplier for more information about which cable is best suited for your measurement configuration.

DECAQ systems operate within a range of 10 - 30 VDC voltage. When running the DECAQ from lower voltages, the resulting increased current could cause power cables and connectors to heat up. A lowered supply voltage increases the current flowing through the resistance of the cable and connector, resulting in a quadratic rise in temperature.

When powering larger DECAQ systems, it is therefore recommended to:

When switching off your system, make sure it is being powered down using either the Web Server or the User Interface Buttons on the chassis front panel. Switching off the system by merely disconnecting the power supply could result in permanent hardware damage.

Additionally, avoid disconnecting the power supply if a battery is not present. The system’s battery power will ensure the protection of your hardware and/or recorded data if the power supply gets disconnected. If you need to switch off the system while it is running on battery power only, please do so using the Web Server or User Interface Buttons (see above).

| Warning |

|---|

| Do not switch off or reset your DECAQ system while it is booting or while a firmware upgrade is in progress. This could permanently damage the system. Wait for the display to show ‘IDLE’, ‘LIVE’, ‘REC’, or ‘FAIL’ before continuing to operate on the system. |

The following table provides information which serves as a guideline when choosing the appropriate power cable for your external power connection:

| Termination | Max Current | Length | Name |

|---|---|---|---|

| Mean Well AC-DC Adapters | 15.0 A | 1.0 m | 230K |

| Mean Well AC-DC Adapters | 15.0 A | Variable | 231K |

| Banana Plugs | 15.0 A | 2.0 m | 213K |

| Cigarette Plugs | 15.0 A | 2.0 m | 214K |

| Banana Plugs | 20.0 A | 2.0 m | 216K |

| Banana Plugs | 20.0 A | Variable | 221K |

Suggested power cables for different system configurations

| Power Source | Power Source | Power Source | Power Source | Power Source | Power Source | |

|---|---|---|---|---|---|---|

| Signal Conditioning and Channel Count | Bench / Battery | Bench / Battery | Cigarette Lighter Socket | Mean Well (15 V) Part Numbers: GST160A15-R7B GST220A15-R7B | Mean Well (24 V) Part Number: GST120A24-R7B GST220A24-R7B | TDK Lambda (26 V, 260 W) Part Number: ZUP36-12 |

| Up to 5 [1] signal conditioning boards / up to 120 channels | 213K | 216K, 221K | 214K | 230K, 231K | 230K, 231K | 213K, 216K, 221K |

| Up to 8 [2]signal conditioning boards / up to 192 channels | 213K | 216K, 221K | 214K | 230K, 231K | 230K, 231K | 213K, 216K, 221K |

[1] Depending on Module configuration and sampling rate

[2] Depending on Module configuration and sampling rate

Power Usage

| Chassis Size | DECAQ-02 | DECAQ-03 | DECAQ-04 | DECAQ-06 |

|---|---|---|---|---|

| With most demanding Modules [1] | 42 W | 64 W | 84 W | 124 W |

| With most demanding Modules [1] and Dynamic Charging on | 47 W | 69 W | 92 W | 134 W |

| Battery charging when system is OFF | 85 W | 85 W | 85 W | 85 W |

[1] The term ‘most demanding Modules’ is used to denote the following configuration:

The recommended power supply wattage depends on the size of your DECAQ chassis. The following table summarizes the recommended power supply for each DECAQ chassis size:

| Chassis Size | DECAQ-02, DECAQ-03 and DECAQ-04 | DECAQ-06 |

|---|---|---|

| Recommended Mean Well power adapter (15 V) [1] | GST160A15-R7B (15 V 144 W) Cable: 230K, 231K | GST220A15-R7B (15 V 201 W) Cable: 230K, 231K |

| Recommended Mean Well power adapter (24 V) [2] | GST120A24-R7B (24 V 120 W) Cable: 230K, 231K | GST220A24-R7B (24 V 221 W) Cable: 230K, 231K |

[1] 15 V Mean Well power adapters are ideal for use with ICS, WSB and THM Modules

[2] 24 V Mean Well power adapters are ideal for use with ALI Modules

When operating either high channel counts (typical of DECAQ-06 DECAQ chassis configurations) or while using the Dynamic Charge feature (see information about DECAQ Battery maintenance below), the following recommended input voltages should be applied:

| DC Input Voltage | Input Current | Fuse | |

|---|---|---|---|

| Min | 10 V | - | 25 A |

| Max | 30 V | 20 A | - |

| Recommended | > 15 V | < 16 A | - |

All DECAQ systems contain an internal battery pack. When the power input voltage to the DECAQ drops below the threshold voltage (which is typically 8.5 V), the DECAQ’s UPS will power the system using the battery pack.

If the DECAQ runs from its battery pack, the Battery LED will turn green. Once the system’s power input voltage rises above the threshold (typically 9.5 V), the UPS will automatically switch back to the DECAQ’s power input as its primary power supply.

The DECAQ can run from the battery pack for a specified battery pack temperature of between -20 °C and 65 °C, although battery capacity will decrease at low temperatures.

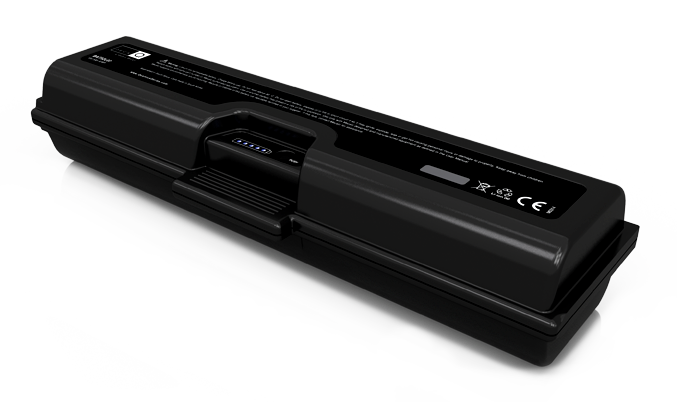

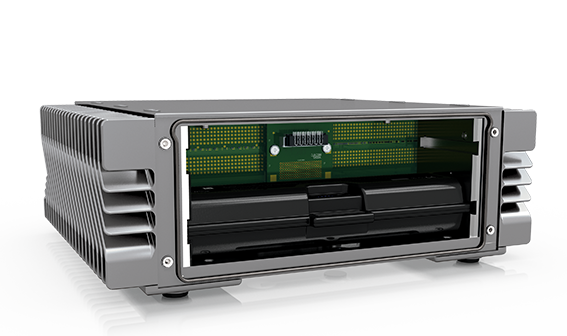

The DECAQ has been designed with portable measurements in mind. Battery Cartridges may be added to any size mainframe for up to two hours of field measurements. Batteries are interchangeable and may be swapped in the field to support longer measurement tasks.

Battery and cartridge description

| Item | Description |

|---|---|

| DECAQ Battery | Li-Ion Battery 90 Wh Capacity Systems come standard with one removable battery |

| BMUX | Standard Battery Cartridge. All DECAQ systems come populated with the BMUX Battery Cartridge and one removeable battery |

| BMUXS | Battery Cartridge for additional batteries. Compatible with DECAQ-04, DECAQ-06. Populate your system with up to 3 batteries |

Battery and cartridge combinations

| SYSTEM | SYSTEM WITHOUT BATTERIES | BATTERY CAPACITY BMUX BATTERY CARTRIDGE STANDARD - 1 REMOVEABLE BATTERY | BATTERY CAPACITY BMUX BATTERY CARTRIDGE FOR ADDITIONAL BATTERIES |

|---|---|---|---|

| DECAQ-02 |  |

|

N/A |

| DECAQ-03 |  |

|

N/A |

| DECAQ-04 |  |

|

Max

2 removeable batteries Max

2 removeable batteries |

| DECAQ-06 |  |

|

Max

3 removeable batteries Max

3 removeable batteries |

The DECAQ Mainframes have been designed to be able to swap between different batteries.

Removal of a battery inside a Mainframe whilst powered down

Unscrew the hex key from the bottom cover of the DECAQ Mainframe

Use the hex key to unscrew the rear cover plate of the DECAQ Mainframe

Pull out the battery using the tab on its plastic housing

Return the rear cover plate to the DECAQ Mainframe

Return the hex key to the bottom cover of the DECAQ Mainframe

Insertion of a battery into a Mainframe whilst powered down

Charging the battery

There are two ways to charge the DECAQ battery:

Fast Charge

Fast charge can only be performed if the DECAQ is switched off. Charging times vary according to the chassis size – a 2-slot DECAQ with only one battery takes 2 hours to charge (the fastest charging time), whereas the 6- slot DECAQ with up to three batteries takes 5 hours to charge (the slowest charging time).

Fast charging will start automatically when external power is first connected to the DECAQ or when the DECAQ is switched off and the battery is not yet fully charged.

Fast charge uses approximately 90 W of electrical input power. If the input power supply is not capable of providing the power, the system might reset. This method also introduces additional heat into the system. It is therefore highly recommended that it be performed in an area with a free flow of cool air.

Dynamic Charge

This setting charges the battery as fast as possible while the DECAQ is switched on. With Dynamic Charge, all available power (up to 40 W) not being used by the system is diverted to the battery.

Input Currents and System Temperature

Dynamic Charge requires the total input current to be less than the set current limit before it will start charging. Once the system’s input current is less than the system current limit, charging will commence. Thereafter, the battery charge current will increase until maximum charge current is reached, or the input current rises to above the system current limit.

If the total input current rises above the system current limit during charging, the charge current will be reduced until the input current is below the system current limit or until zero charge current has been reached. Once zero charge current has been reached, the charge current will only increase once input current to the system falls below the system current limit.

Dynamic Charge Cycles and Termination

Dynamic Charge will start a charge cycle if the battery is not 100% full.

Dynamic Charge will terminate when:

The battery is fully charged (the battery is fully charged).

The main input power has been lost and the system goes into backup mode.

A fault is detected in the battery.

Dynamic Charge Deactivation

Once the setting has been changed to Dynamic Charge, the system will use it as the default setting. The setting can then be deactivated via the Web Server and will stay deactivated until the User activates the setting again.

Fast Charge does not affect Dynamic Charge (which is only applicable once the system is operational (DECAQ switched on)).

Only one of these two charge algorithms can be active at any given time.

The battery has to be charged for the DECAQ’s uninterruptible power supply (UPS) to supply the system with backup power. You can use any of the two settings to recharge a discharged battery. Fast charge is managed automatically when the system is switched off. Dynamic charge can be selected on the Web Interface.

The most efficient way of maintaining the battery is to use the new ‘Dynamic Charge’ setting. Dynamic Charge will ensure the system automatically keeps the battery in a fully charged state.

Alternatively, ‘Fast Charge’ can also be used to fully recharge a battery that has been depleted.

| Please note |

|---|

| If the external power source is removed while Dynamic Charge is in progress, the DECAQ will stop charging and switch to backup mode and run from the battery. If the external power source is removed while Fast Charge is in progress, the DECAQ will stop charging and switch off. Due to the properties of Li-Ion rechargeable batteries, recharging can only be initiated when the battery is between 0 °C and 45 °C. Once the temperature exceeds 50 °C while charging, charging is suspended and the Battery LED will flash red. Charging will resume once the battery temperature drops below 45 °C. Charging will also be suspended if the battery temperature drops below 0 °C, and will resume once the battery temperature rises to above 2 °C. |

| The Battery LED will flash red when the battery pack has gone above 50 °C or below 0 °C while being charged. In both cases, the system will cease to charge the battery: < 0 °C. While the battery pack is being charged, the battery pack will suspend charging once the temperature is < 0 °C. Once this happens, the Battery LED will flash red. Charging will resume once the battery temperature rises to above 2 °C. |

| 0 °C - 45 °C This is the valid battery pack temperature range for starting a charge cycle. The Battery LED will flash blue while charging. > 50 °C While the battery pack is being charged, the temperature at which the battery pack will suspend charging is > 50 °C. Once this happens, the Battery Led will flash red. This is for safety reasons as it is better for the battery pack to be charged at lower levels. Charging will resume once the battery temperature drops below 45 °C. |

Recommended battery replacement interval (Li-Ion batteries)

To ensure Li-Ion batteries are functioning at full capacity, it is recommended they be replaced every three years.

Mecalc does not repair batteries that are out of warranty. Please ensure that spent batteries are disposed of responsibly by recycling them at local recycling facilities in accordance with relevant local regulations. Proper disposal helps protect the environment and reduces hazardous waste. Contact your local waste management services for guidance on battery recycling locations and procedures.

Battery Care

For optimum battery care, charge or discharge DECAQ batteries to approximately 50% capacity at least once every six months. This ensures batteries maintain their maximum energy capacity. Store the battery at temperatures between 5 °C and 20 °C (41 °F and 68 °F) and 50% capacity.

Before switching on the DECAQ, make sure it is being powered with an external power source or contains a charged battery.

Switch on the DECAQ via the User Interface by applying the following steps:

See Navigating the DECAQ’s User Interface Display for more information about the User Interface display.

Switch off the DECAQ via the User Interface by applying the following steps:

| Please note |

|---|

| Take care not to switch off your DECAQ while it is running a test. The procedure above will shut down the system irrespective of whether a test is being run or not. Please ensure the test sequence has concluded before switching off the system, since valuable data may be lost if the test is still running. |

The DECAQ can be connected to a Notebook / PC / network / smart device through Ethernet and/or Wi-Fi.

A built-in 2 MIMO streams IEEE 802.11b/g/n Wi-Fi network interface is available on the DECAQ. The Wi-Fi network interface can be used where truly mobile operation of the DECAQ is required.

The default configuration for the DECAQ Wi-Fi interface is:

Connect to the DECAQ with your compatible Wi-Fi device using the SSID mentioned above. To test connectivity, use the default IP address as the URL in a web browser, for example, http://192.168.2.204.

The default mDNS name may also be used in compatible web browsers, for example, http://Quantus_1234S5678.local.

The browser should then display the DECAQ’s “System Overview” page. The DECAQ’s start-up Wi-Fi interface configuration parameters can be edited in the Web Server’s network setting configuration pages.

Effective Wi-Fi data streaming rates of up to 2.7 MB/s can be achieved with your DECAQ. Please note that your DECAQ Wi-Fi connection performance is highly dependent on its connection settings, as well as environmental factors including (but not limited to) distance, interference and shared bandwidth.

| Please note |

|---|

| When configuring the Wi-Fi interface, the settings for “Country”, “IP address” and “Subnet mask” might be different depending on the country in which you are setting up the device. |

A Gigabit Ethernet connection (1000 BASE-T) is available on the DECAQ’s front panel that can accept compatible Ethernet cables. When using Ethernet on the DECAQ use only a CAT5e UTP cable. This will ensure the correct screening of signals throughout the length of the cable.

The default configuration for the DECAQ Ethernet interface is:

To use the Ethernet interface, simply plug in an Ethernet cable. The DECAQ will automatically detect the Ethernet cable and initialize it as the primary network interface. Use a Gigabit Ethernet enabled link partner (network device or PC) for best performance.

To test connectivity to the DECAQ, use a web browser that supports mDNS and enter the URL “http://Quantus_1234S5678.local” (replace “1234S5678” with the Serial Number of the DECAQ).

The browser should then display the DECAQ “System Overview” page. The DECAQ’s start-up Ethernet interface configuration parameters can be edited in the Web Server’s network setting configuration pages.

Once booted, the User Interface can also be used to display the system’s IP address. The DECAQ Web Server can then be used (with the IP address as the URL) to make modifications to the network set-up.

Ethernet Connection Range and Cables

Gigabit Ethernet over copper (1000BASE-T) connections allow for cable lengths of up to 100 m. If a longer connection distance is required, active repeaters need to be used at each 100 m interval.

DECAQ system information is available on the Web Server. This includes all boards that make up the specific system, their serial numbers and firmware. The following DECAQ parameters are shown and can be configured via the Web Server (please note the user interface of the web server depends on the firmware version and some settings may not be applicable):

)

Button and the OK Button).

)

Button and the OK Button).

To control the User Interface, press the Scroll Button to scroll down the menu options shown on the display. Use the OK Button to select an item from the menu to execute its related command. As a safety feature the display might show ‘SURE?’, asking the user to confirm the command before the system will execute it.

Options on the User Interface will continue to loop if the user continues to press the Scroll Button.

The OLED display is automatically dimmed when no screen or User input activity has been detected.

| Please note |

|---|

| Do not switch off or reset the DECAQ while it is busy booting or while a firmware upgrade is taking place, as this could permanently damage the system. Wait for the User Interface to display ‘IDLE’, ‘LIVE’, ‘REC’ or ‘FAIL’ before executing additional commands. |

The following menu options will be available on the User Interface display once the DECAQ has been switched on (to scroll through these options, press the Scroll Button until the option appears on the display):

|

IDLE Default text displayed on the DECAQ User Interface |

|

IP? Displays the mDNS name, IP address of LAN and Wi-Fi |

|

RESET? Reset the DECAQ |

|

OFF? Power down the DECAQ |

|

TEMP? Power Supply temperature |

|

INFO? Information and firmware revisions of the DECAQ |

|

DEFAULT? Changes boot parameters of the DECAQ back to the system’s default settings |

The menu options on the User Interface cycle in a repetitive loop – press the Scroll Button to scroll from INFO? to IP? and so on.

To display the IP address on the User Interface display:

To reset the DECAQ:

| Please note |

|---|

| Resetting the system using this procedure overrides any operation currently being performed. The DECAQ will therefore be reset irrespective of whether a test is running or not, increasing the risk that valuable data may be lost. |

To let the display show the status of the chassis temperature:

The display will show OK and thereafter the temperature of the chassis, for example 40 °C.

This menu option shows information and firmware versions related to the DECAQ.

To view the information:

Examples of the information displayed include:

To restore the system to its default boot parameters:

The default boot settings of the DECAQ System board are:

| LAN IP address | DHCP assigned IP address (will default to an Automatic Private IP address such as 169.254.119.144 if no DHCP Server is discovered) |

| LAN DHCP Mode | DHCP client enabled |

| WLAN IP address (if present) | 192.168.2.204 |

| WLAN DHCP Mode | DHCP server enabled |

| LAN / WLAN Bridged Mode | Disabled |

| FTP password | password |

| mDNS name | Quantus_[Serial number printed on the bottom of the system] |

|

SWITCHED OFF / CHARGING While the DECAQ is switched off (and power is available) or charging the internal battery, the User Interface display will either be blank - or display CHARGING. |

|

HELLO To switch on the DECAQ from

this state, press and hold the Scroll

Button until

the LEDs flash and the User Interface displays

HELLO. Button until

the LEDs flash and the User Interface displays

HELLO. |

For more about the User Interface Display and Menu Options while the DECAQ is switched on.

When the DECAQ is switched on it will begin to boot up with firmware stored in its internal Flash memory. There are three stages to booting up correctly:

During boot up the device will show the following messages on the User Interface:

|

BUSY This message is displayed when the system board is booting after Power On (cold boot) |

|

BOOT This message is displayed while the System board is booting |

|

PSU UPGRADE This message is displayed during the Power Supply firmware upgrade. The status LEDs will also flash yellow to indicate the system is still active. This process can take several minutes to complete. The User must not switch off the system during the upgrade. Power Supply firmware upgrades typically take place after the DECAQ has been programmed with new firmware. |

|

FPGA UPGRADE This message is displayed during the FPGA firmware upgrade. The status LEDs will also flash yellow to indicate the system is still active. This process can take several minutes to complete. The User must not switch off the system during the upgrade. FPGA firmware upgrades typically take place after the DECAQ has been programmed with new firmware. |

|

CPLD UPGRADE This message is displayed during the CPLD firmware upgrade. The status LEDs will also flash yellow to indicate the system is still active. This process can take several minutes to complete. The User must not switch off the system during the upgrade. CPLD firmware upgrades typically take place after the DECAQ has been programmed with new firmware. |

|

WAIT This message is displayed when the system board starts to initialize the Signal Conditioning cards. |

|

xx% This is the progress indicator displayed during the Signal Conditioning and QModule boot-up. |

|

IDLE This message will be displayed once the boot-up is complete |

The DECAQ User Interface’s LEDs indicate when the system is active and provides information about different DECAQ Ethernet, Battery and Power statuses.

Below find a brief explanation of each LED action and what it represents:

Ethernet Connector (PTP) LED

The Ethernet connector LED labeled “PTP” is used to indicate the status of the Ethernet link as well as the PTP synchronization status of the system. The following table lists the different states of the LED.

| Solid / Flash / Off | Colour | Description |

|---|---|---|

| Off | N/A | Ethernet is not connected (connection faulty or cable disconnected). |

| Solid | Blue | Ethernet is connected. System is not PTP Slave, not PTP Master and does not have a synchronization fault. |

| Solid | Green | Ethernet is connected and system is PTP Slave. |

| Solid | Red | Ethernet is connected but system has a synchronization fault. |

| Flashing (1 Hz) | Green | Ethernet is connected and system is PTP Master but not PTP Grandmaster. |

| Flashing (0.5 Hz) | Green | Ethernet is connected. System is PTP Master and PTP Grandmaster. |

Battery Status LED

| Solid / Flash / Off | Colour | Description |

|---|---|---|

| Off | N/A | Battery power is not available / not present. |

| Solid | Blue | Battery power is available but isn’t being used to power the system. |

| Solid | Green | Battery is being used to power the system. |

| Solid | Yellow | Battery capacity is less than 25%. |

| Flashing (1 Hz) | Blue | Battery is busy charging. |

| Flashing (1 Hz) | Yellow | Battery capacity is less than 10%. |

| Flashing (1 Hz) | Red | Charging pending. Battery pack temperature is out of range and charge is suspended until battery pack temperature is valid for charging. |

Application LED 1

The LED underneath the User Interface Display on the right is a “soft” LED. The meaning of the LED light changes depending on the application. It could be used to indicate standby / sleep / heartbeat / system activity – it is undefined for now.

DC Power LEMO LED

| Solid / Flash / Off | Colour | Description |

|---|---|---|

| Off | N/A | External power not available. |

| Solid | Blue | External power is available but not being used to power the system. |

| Solid | Green | External power is being used to power the system. |

| Solid | Red | The power input voltage is above or below the allowed voltage range; or the polarity of the input supply is incorrect. |

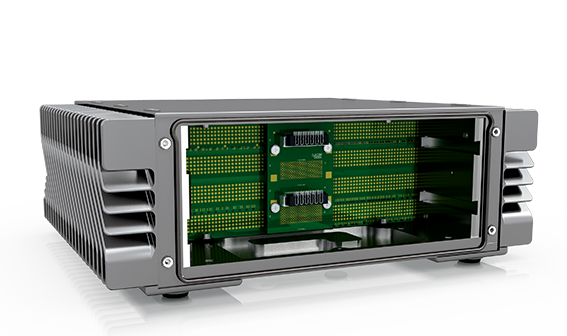

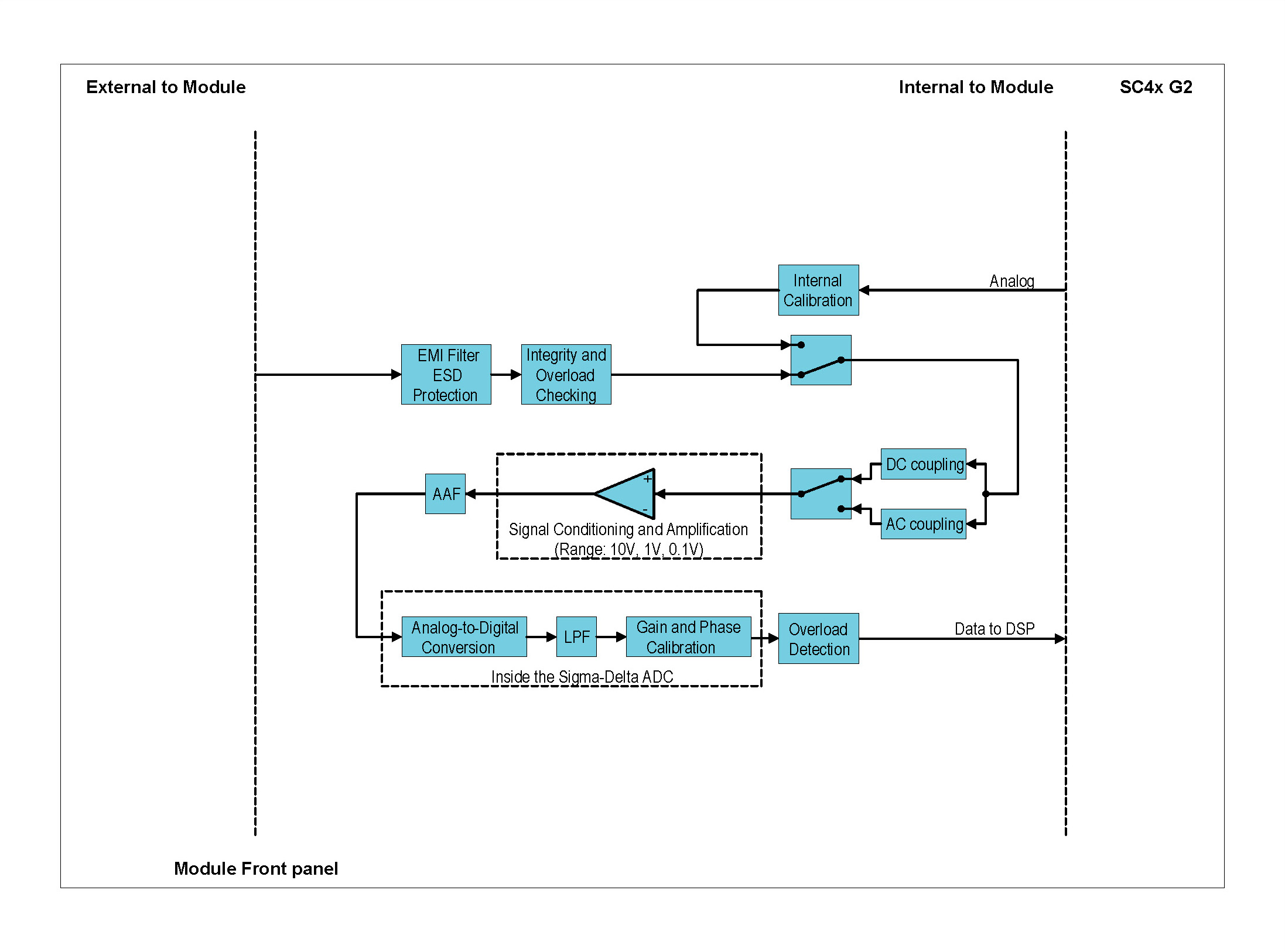

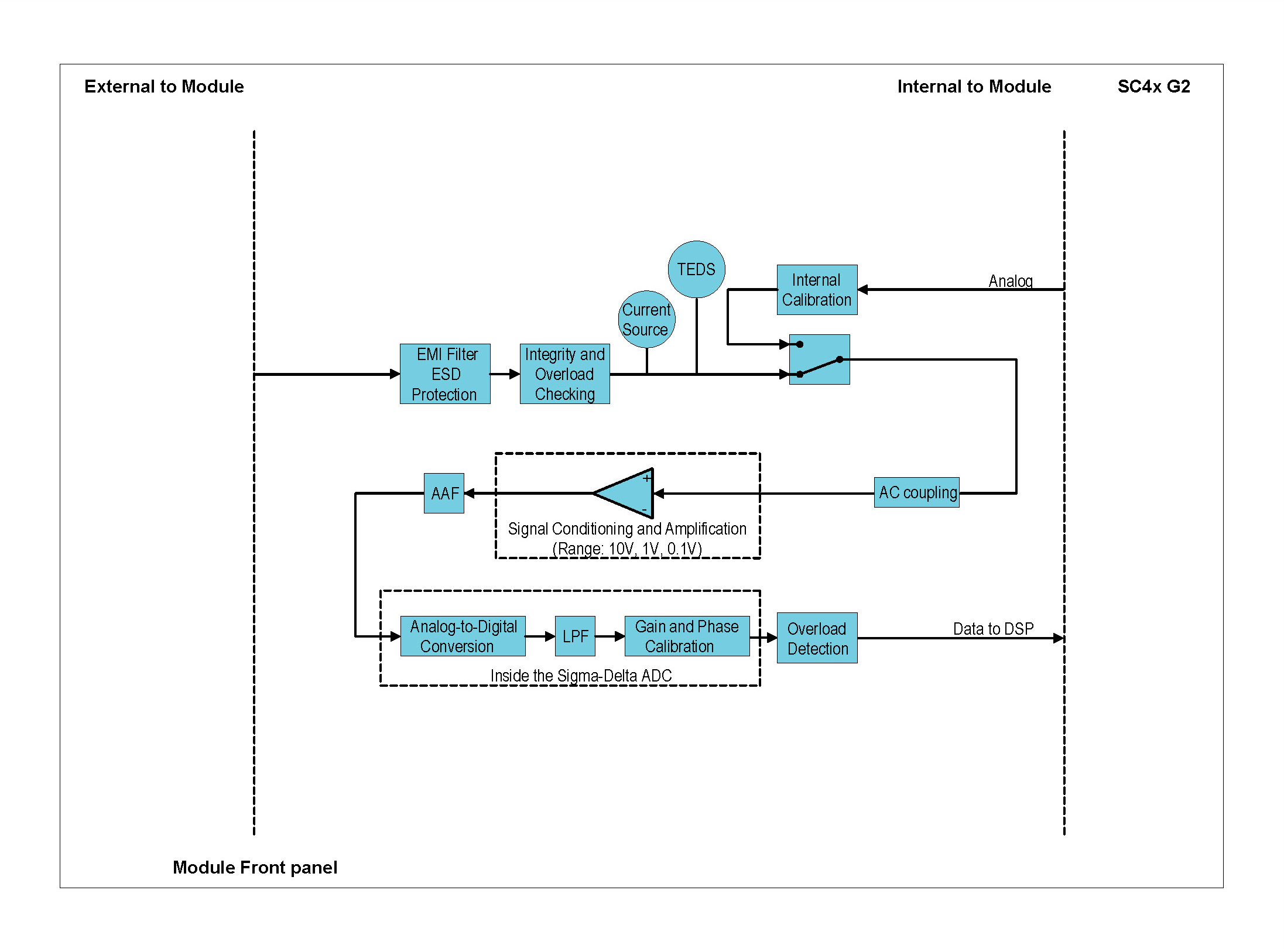

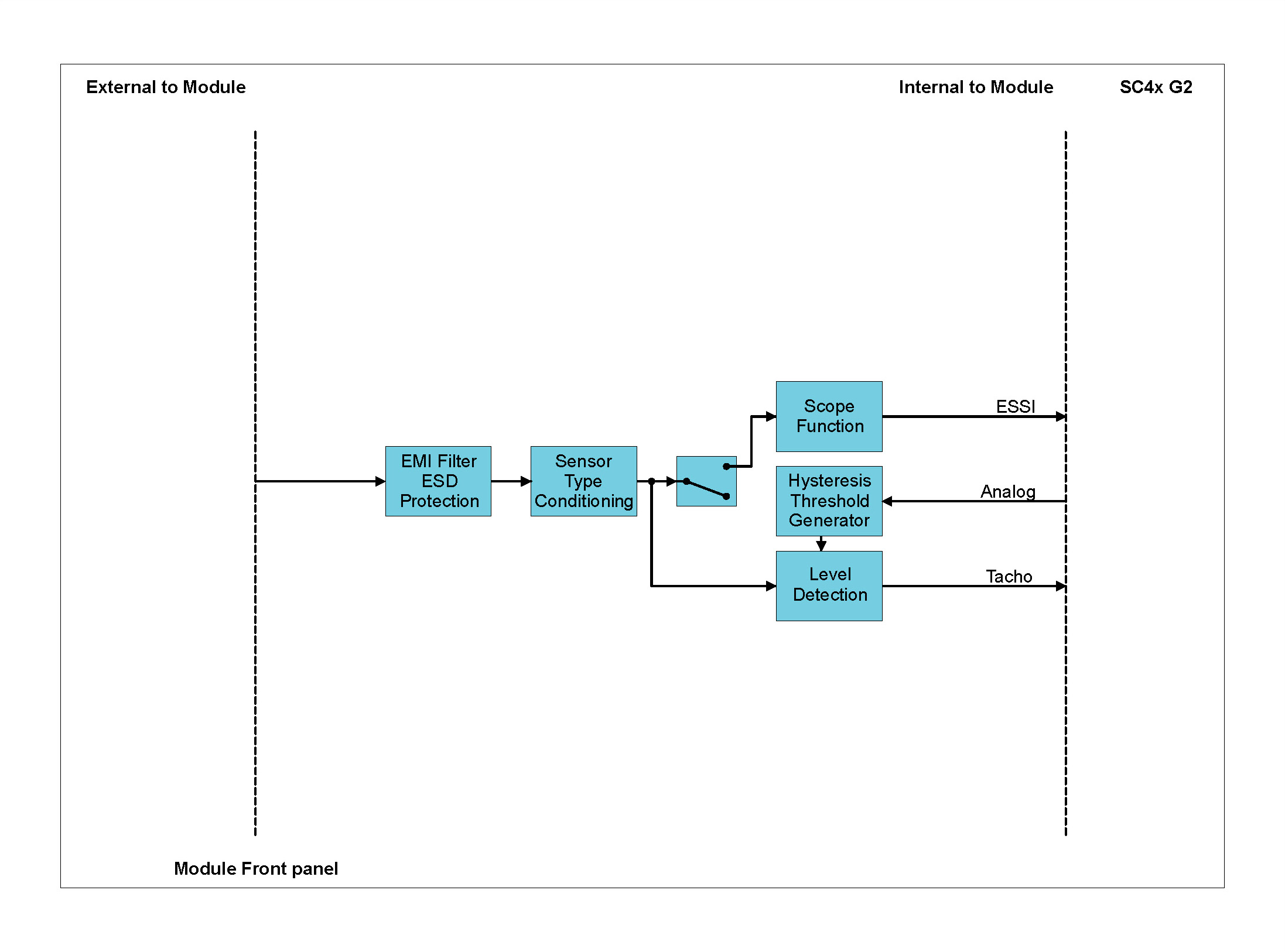

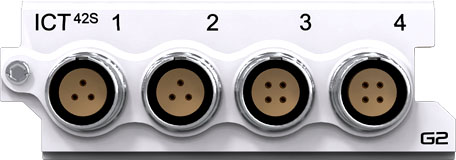

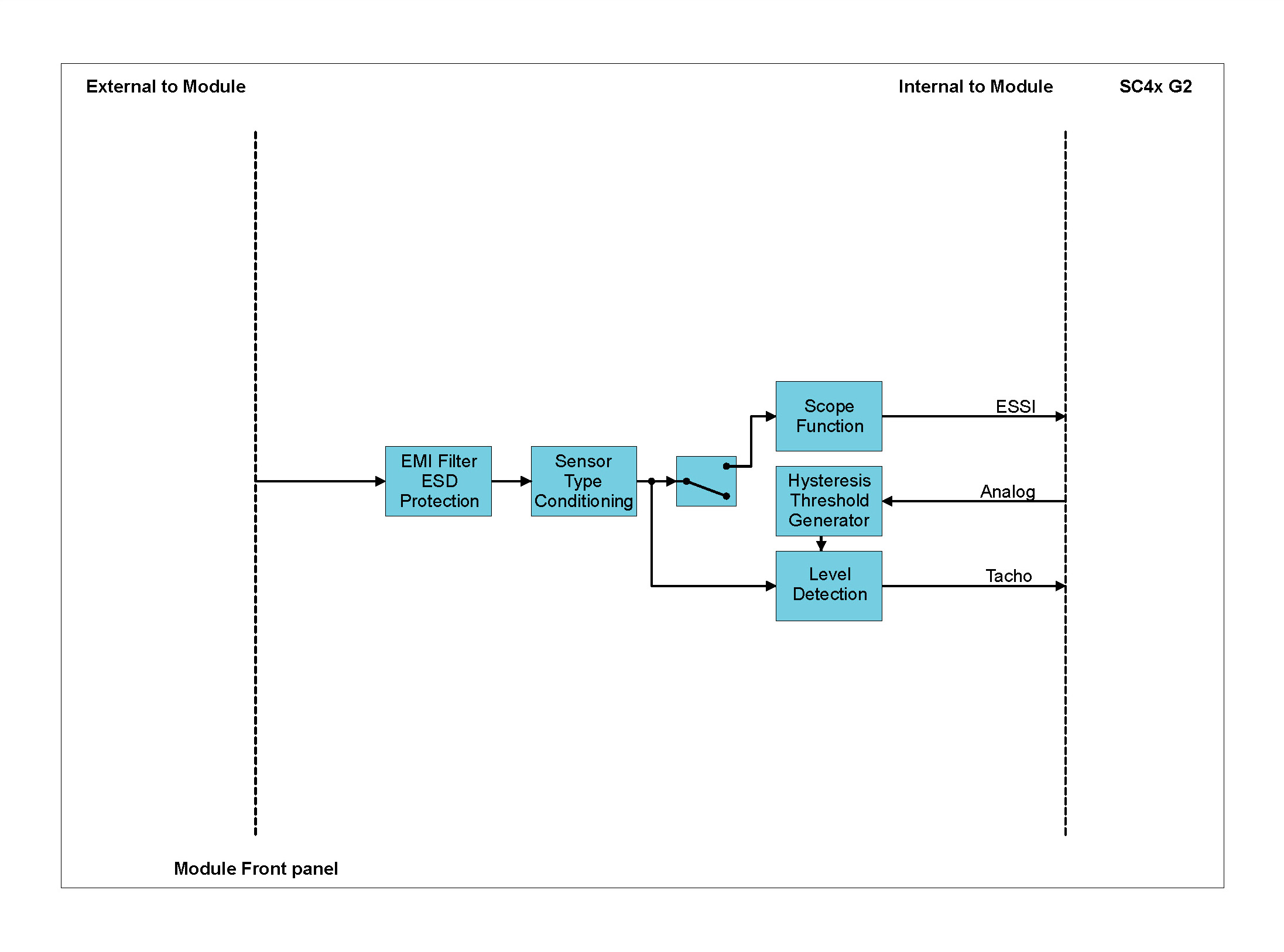

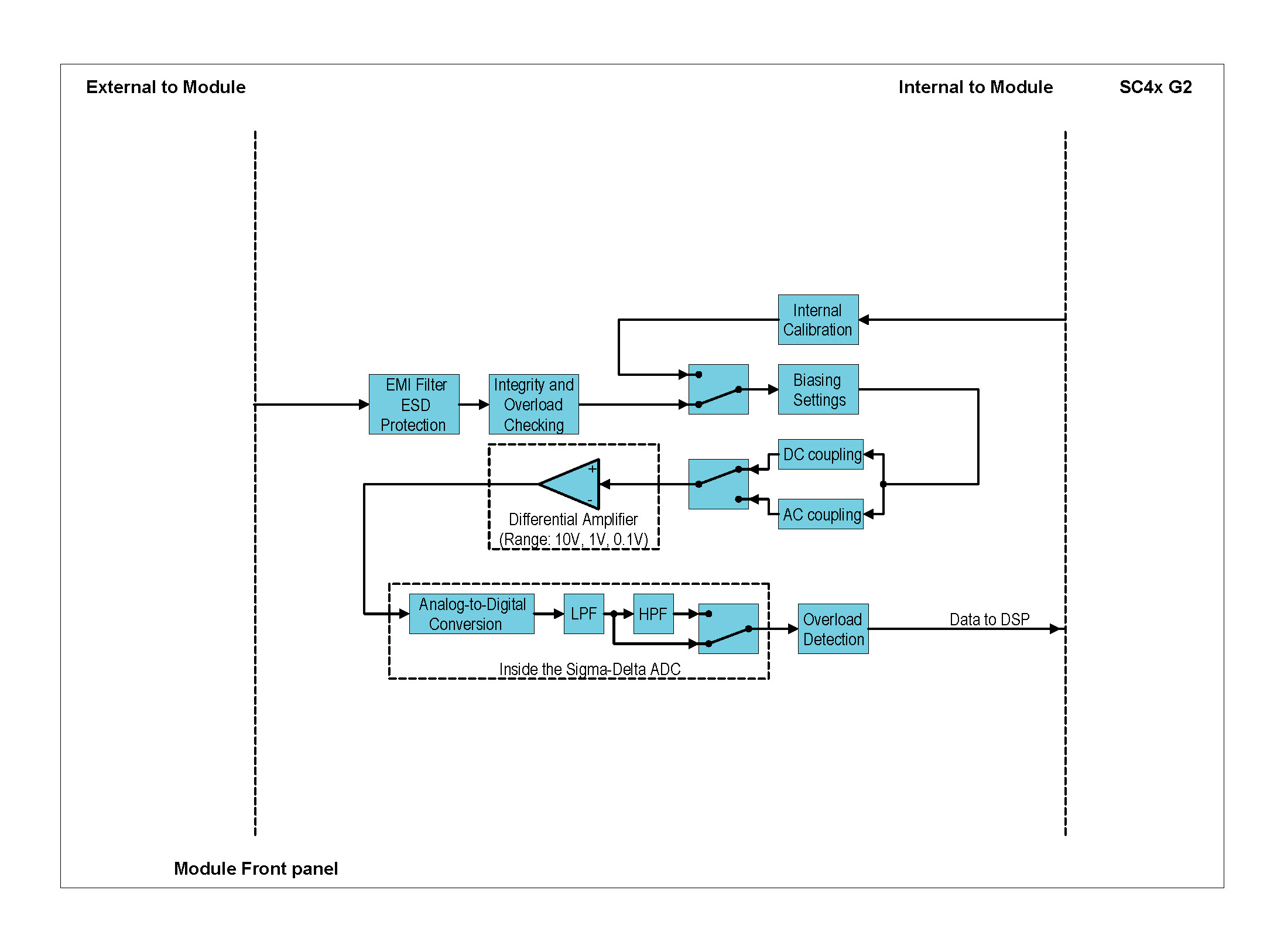

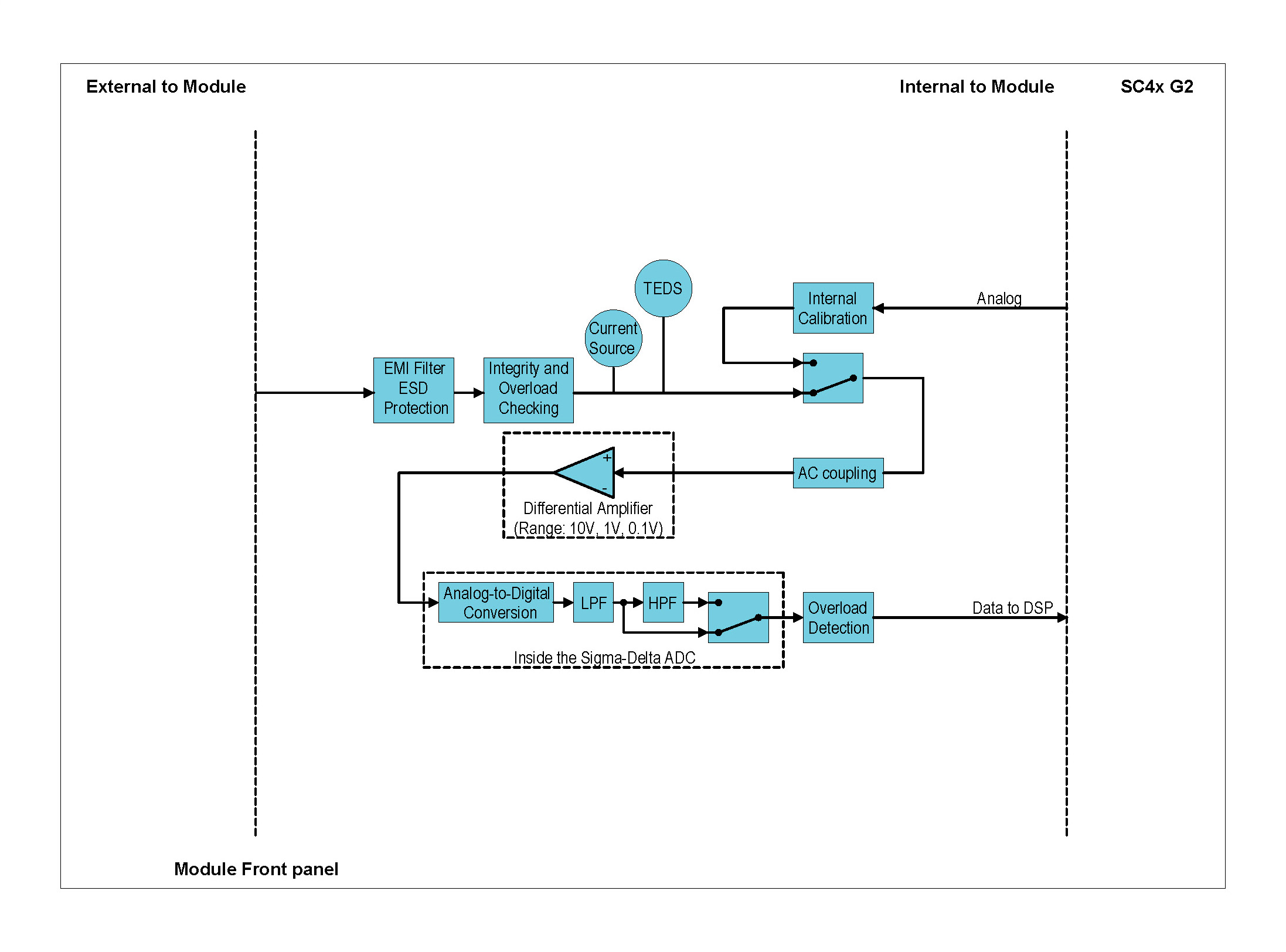

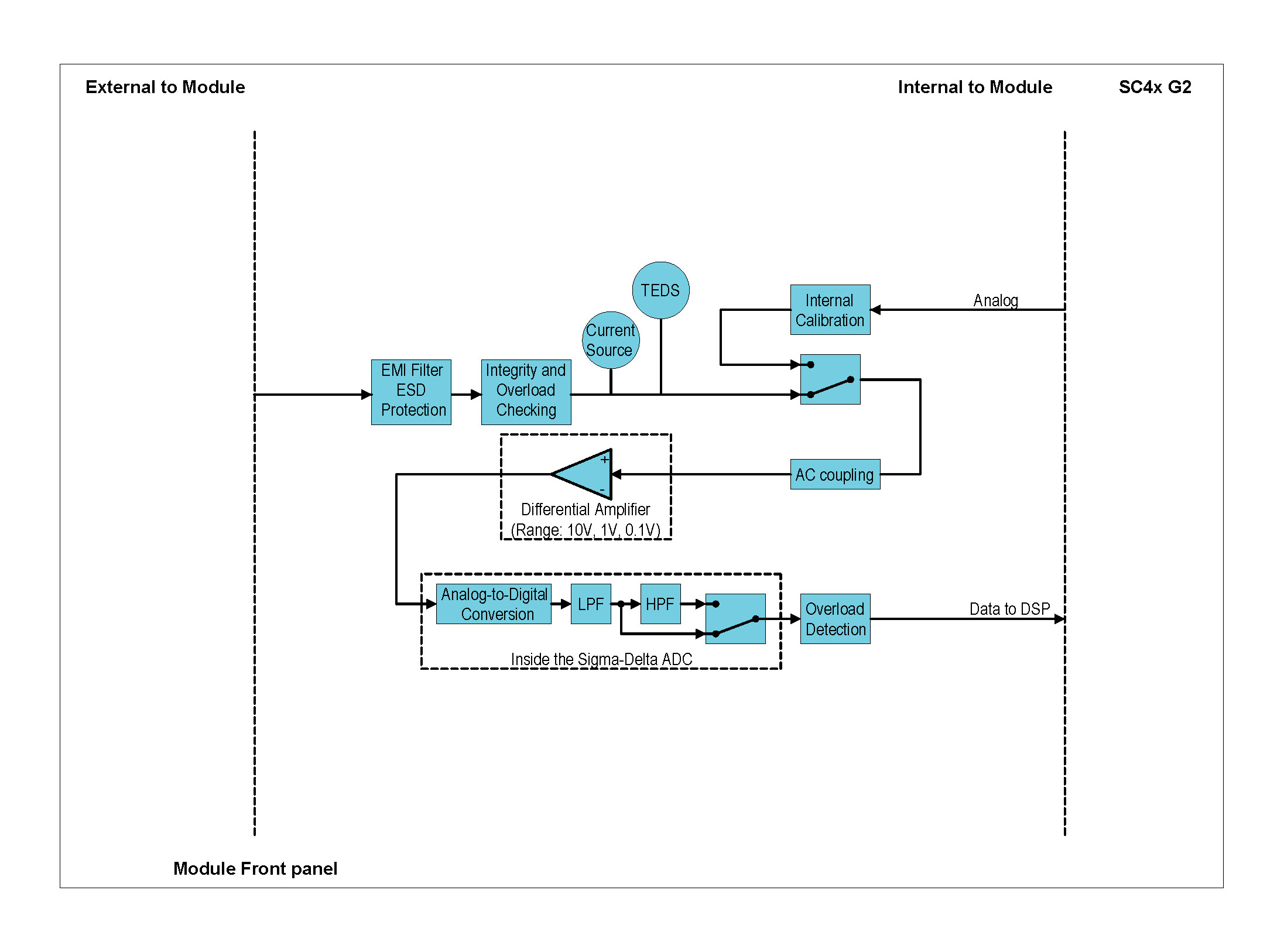

The DECAQ’s Signal Conditioning QModules are housed in the system’s Signal Conditioning boards, each board providing signal processing and mechanical infrastructure for up to 4 QModules.

These boards provide:

The DECAQ system contains multiple slots that support a variety of interchangeable Signal Conditioning channels (QModules), which can be purchased separately and then added and/or swapped as the need arises. QModules are packaged in a robust aluminium casing so as to optimize size and thermal performance, as well as to provide electronic protection.

All QModules include the following features:

Available Modules and a summary of their features are presented in the following section. More information regarding specific Modules (eg. Specification Sheets) is available in separate documents which can be requested from your supplier.

Description

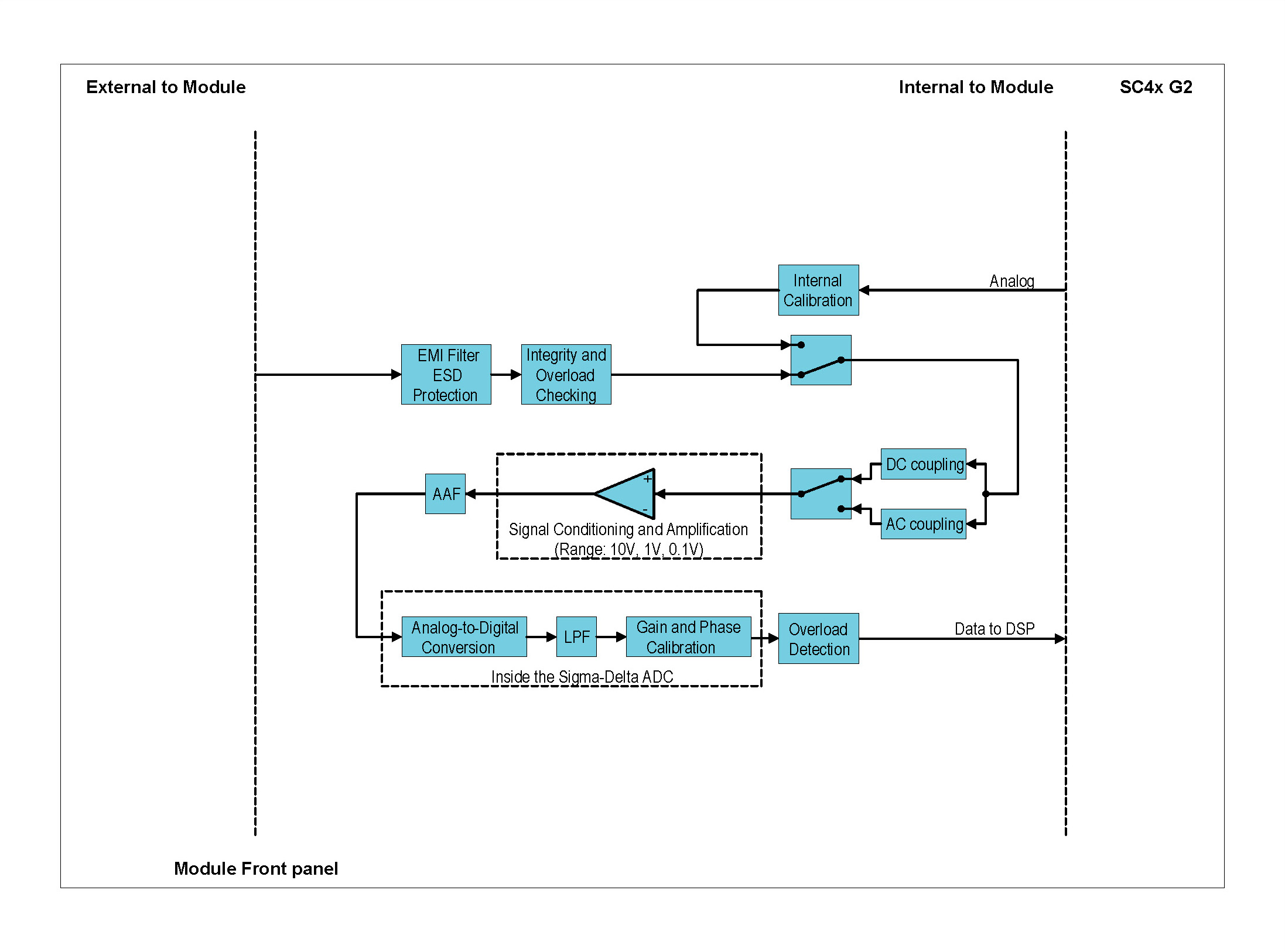

The ICS42 Module can be used with ICP® based accelerometers, force and pressure sensors as well as to measure analog voltages. All 6 channels operate independently of each other, each with their own setting of mode, gain and coupling. The Module can be used:

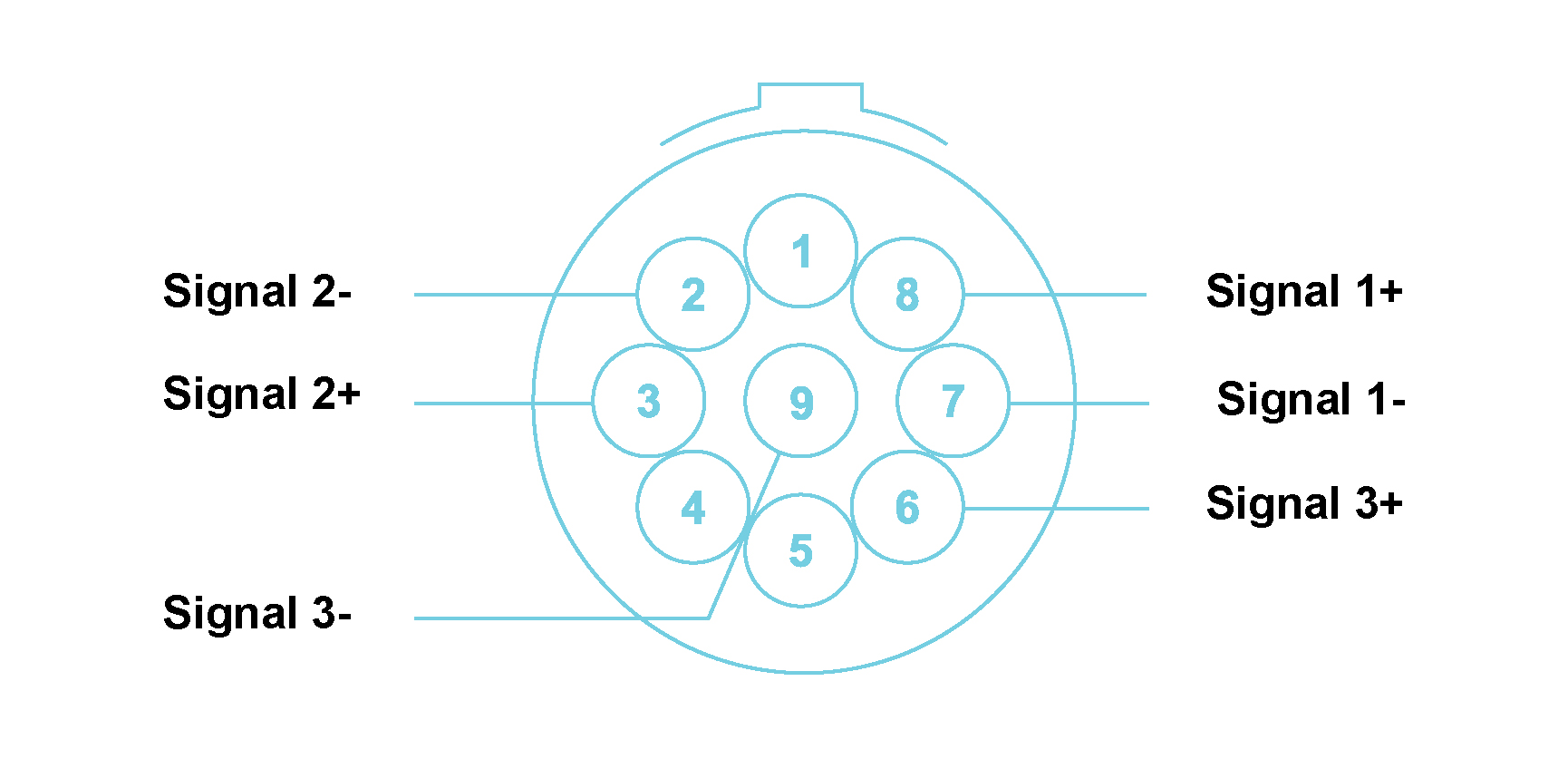

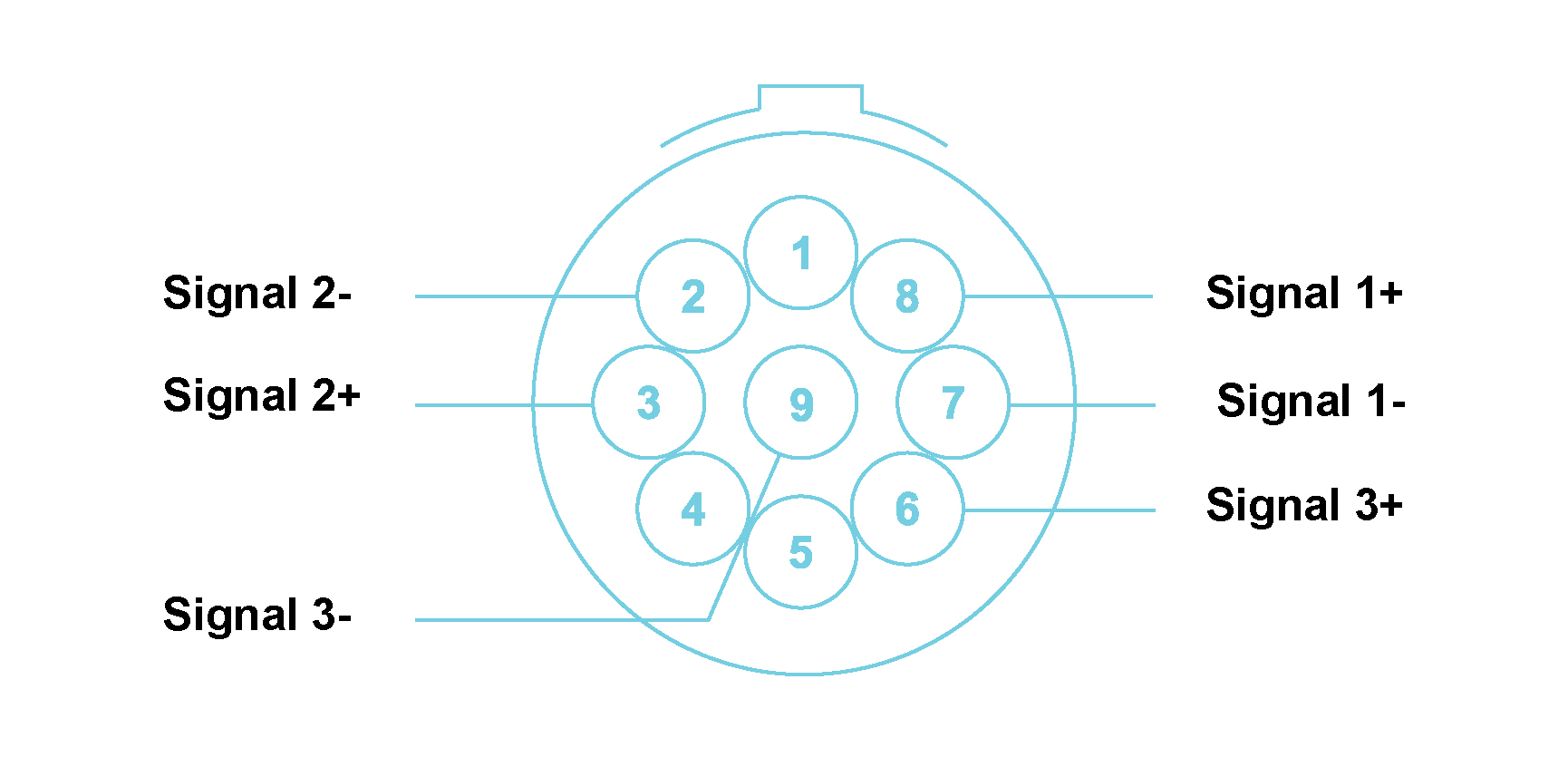

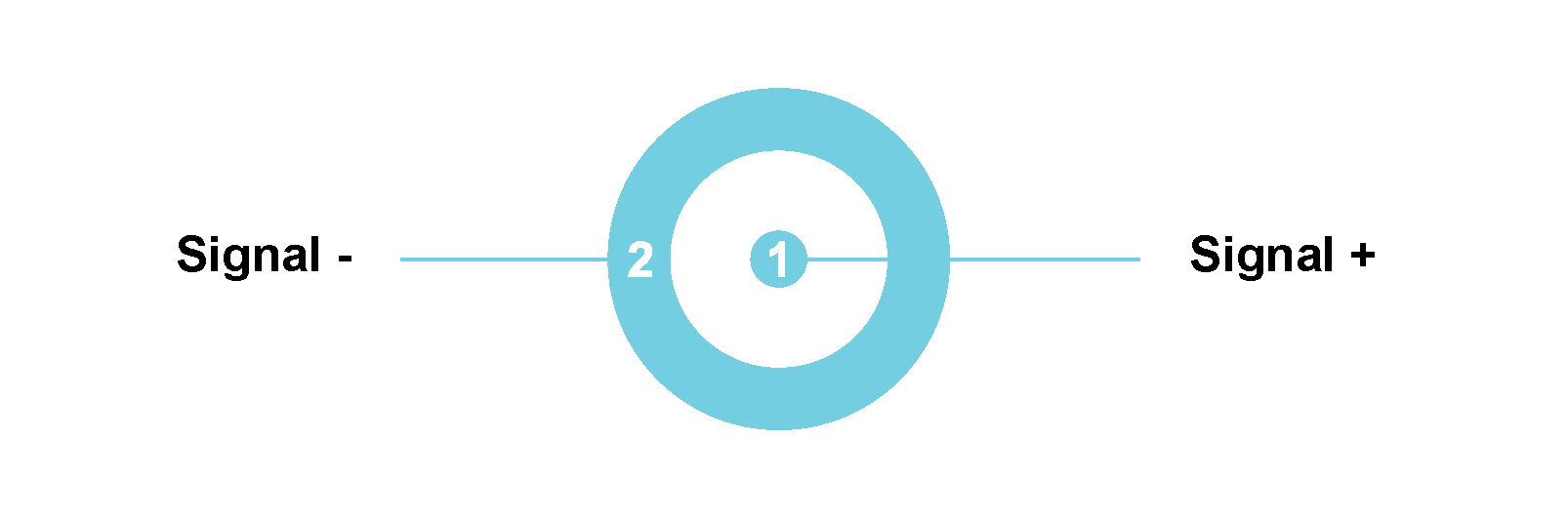

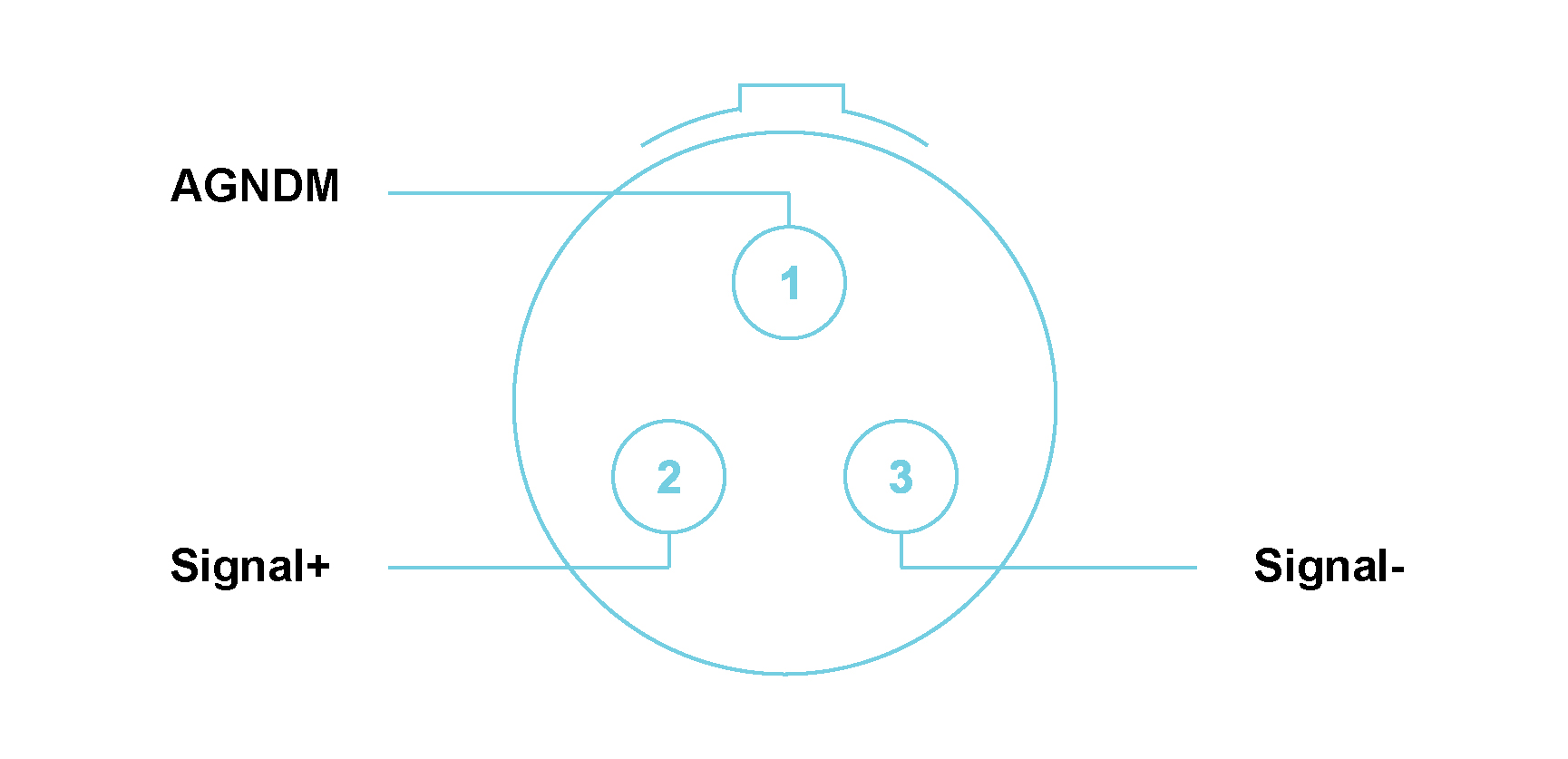

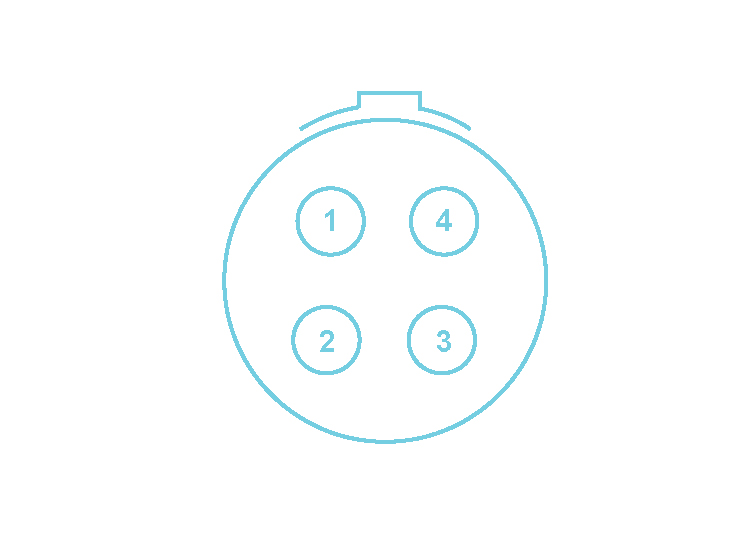

| Front Panel | Connector Information and Pin Definitions |

|---|---|

|

|

ICS42 with LEMO® 9-way EHG.0B connectors Module Pin Definition (when looking into the front panel’s connector or at the rear of the cable’s connector)

Features

Please note:The features and specifications may vary based on the software package utilized with the DECAQ

ICS42 Specifications

| Interface | ICP® | ICP® sensors | |||

| ALI | For analog source voltages | ||||

| Input Coupling | ICP® | AC | |||

| ALI | DC or AC | ||||

| AC Coupling Frequency Response | ICP®/ALI | Attenuation | Min | Max | Unit |

| -3 dB | − | 0.16 | Hz | ||

| Other Sampling Rates | Available through digital LP filters and decimation | ||||

| Optional Programmable Digital IIR Filter | Band pass/stop: 6 dB/octave | ||||

| High/Low pass: 12 dB/octave | |||||

| Optional First Order High-Pass Filter | -3 dB @ 1 Hz | ||||

| Protection | ICP®/ALI | 2 kV ESD | |||

| ICP® | Short circuit between sensor case and ground | ||||

| Galvanic Isolation | 50 V | ||||

| Bandwidth | DC to 44.3 kHz | ||||

| Maximum Sampling Rate (fs) per channel | 102.4 kSa/s | ||||

| A/D Conversion | 24-bit | ||||

| Data Transfer | 24-bit | ||||

| Input Voltage Ranges (Peak) | ±100 mV; ±1 V; ±10 V | ||||

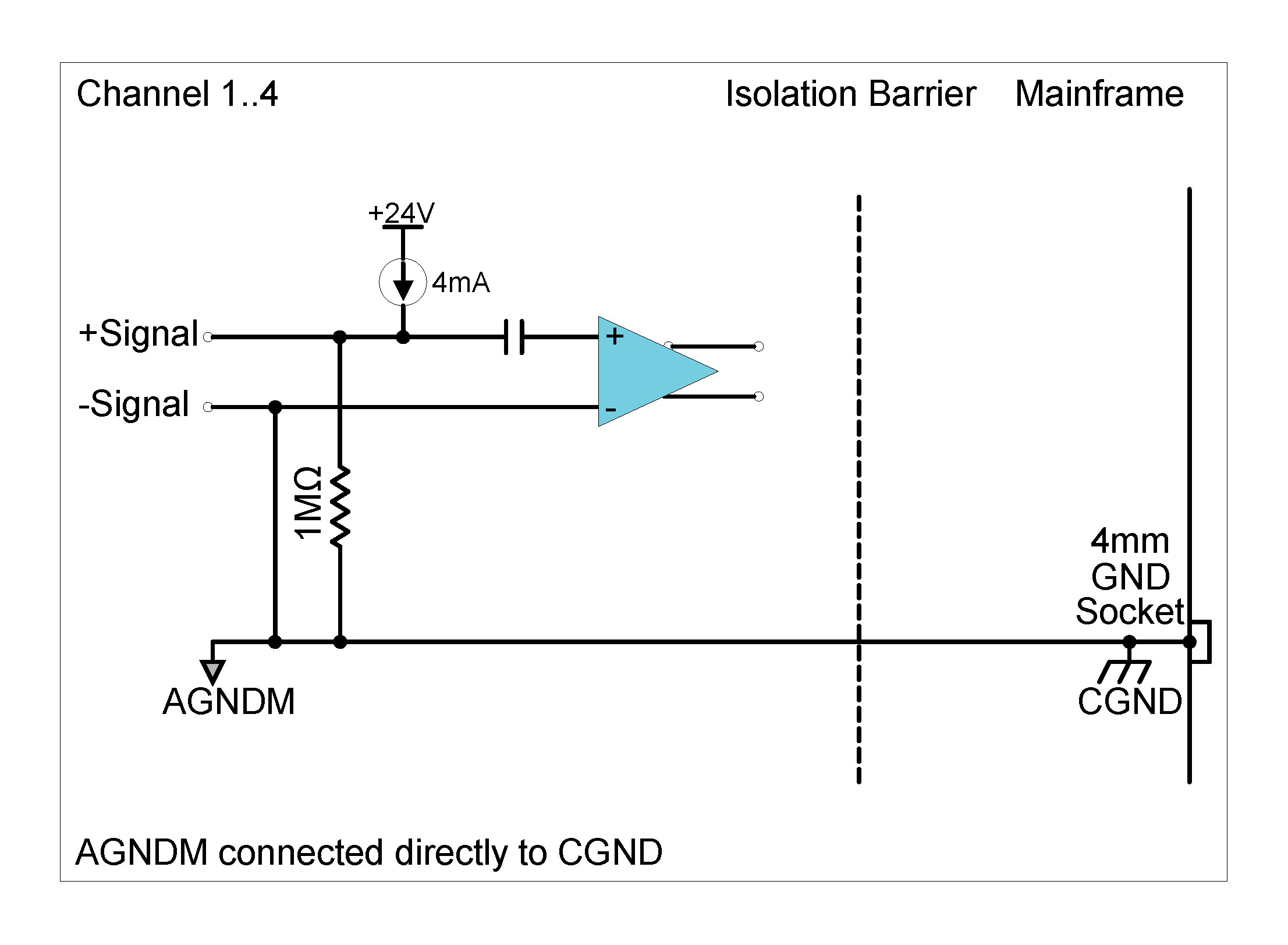

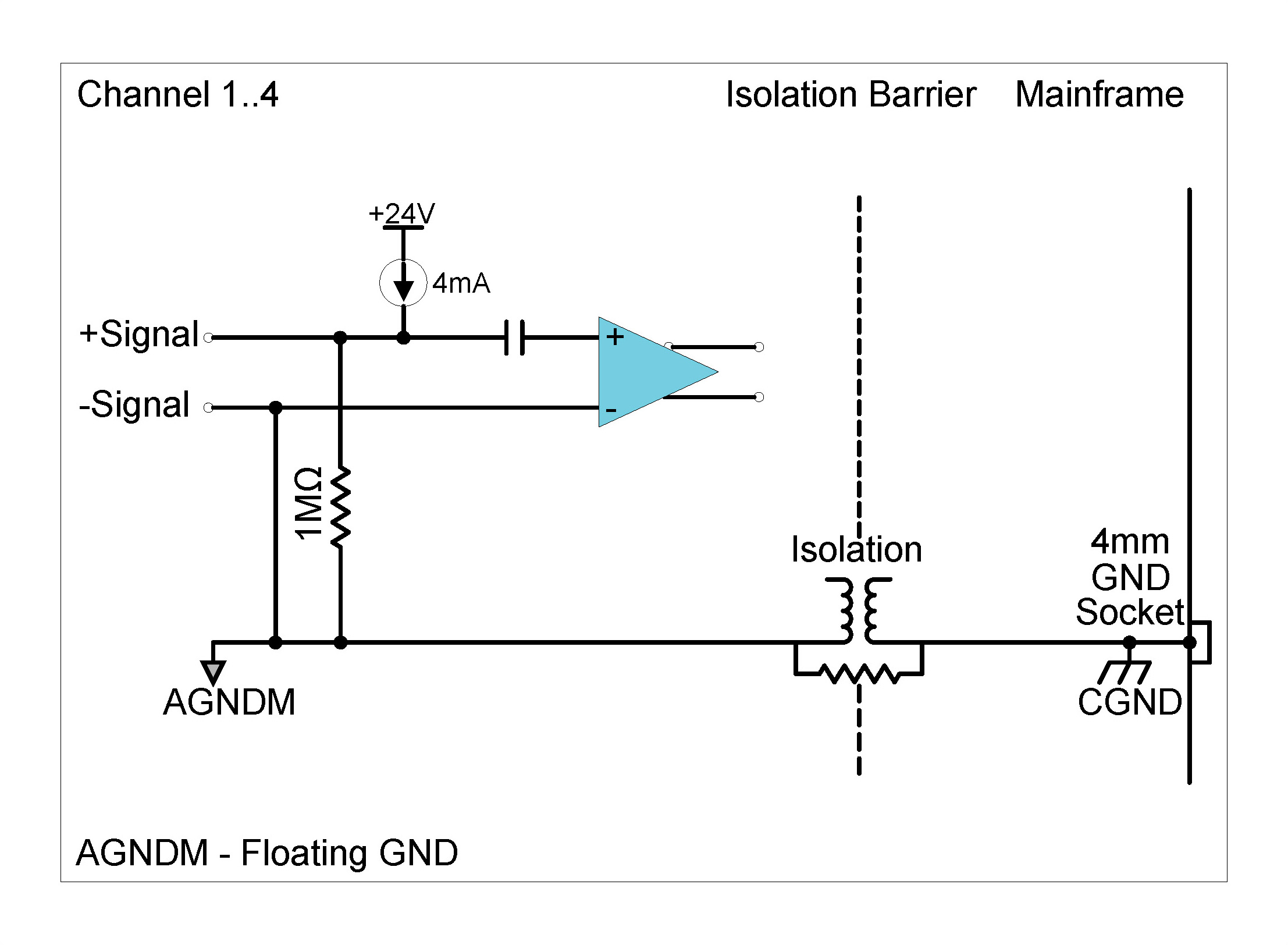

| ICP® mode | 4 mA constant current at 24 V excitation | ||||

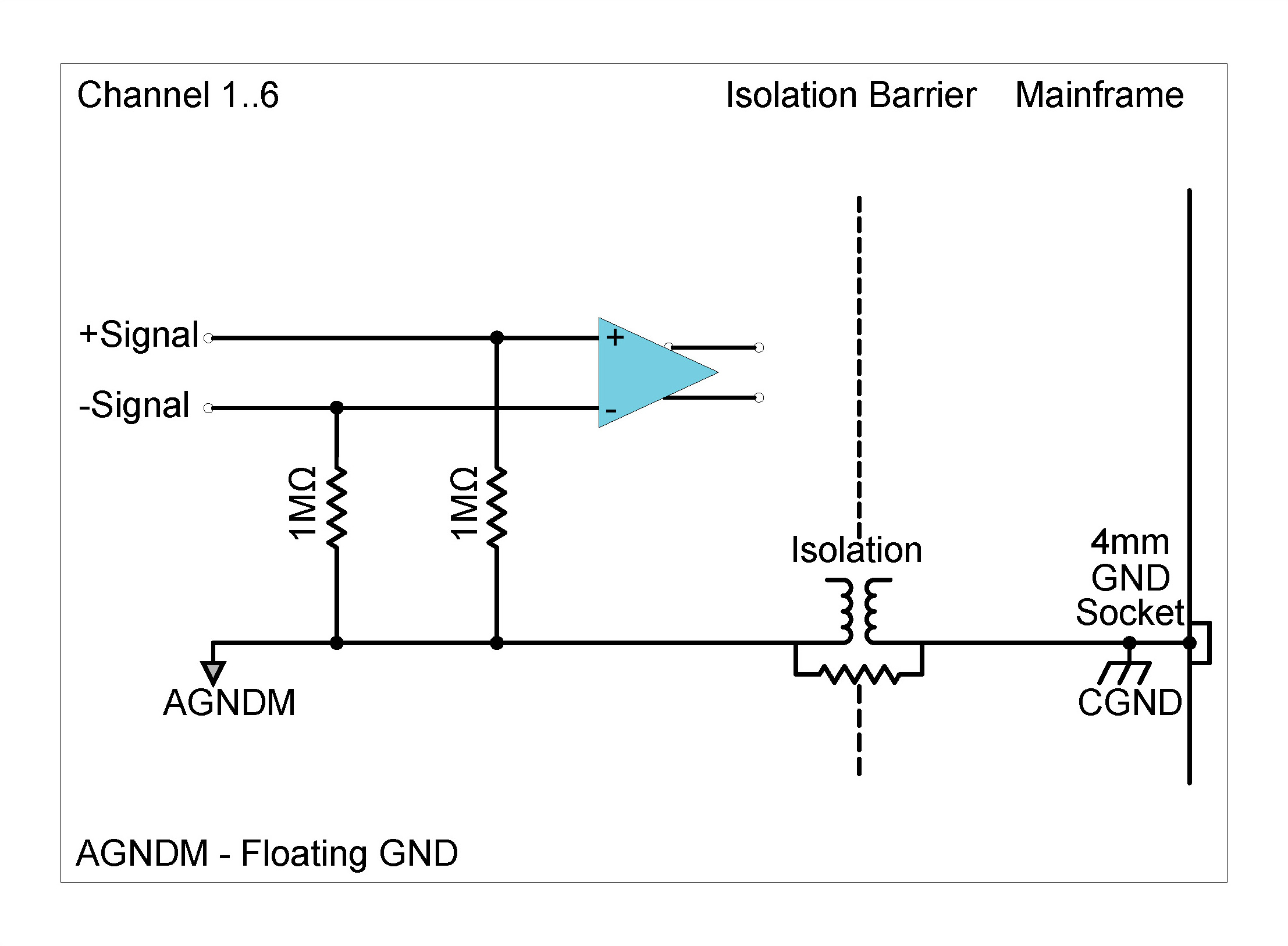

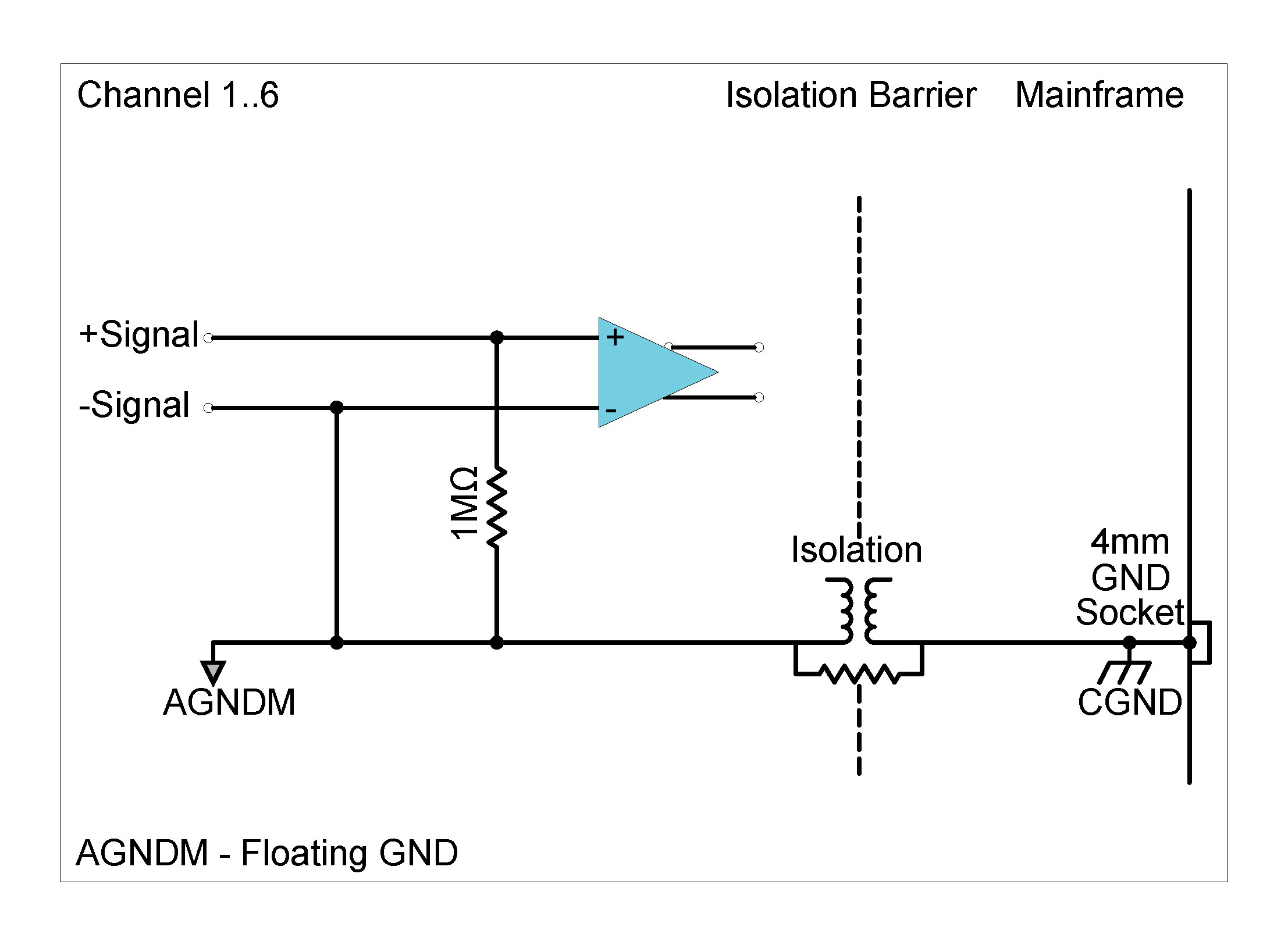

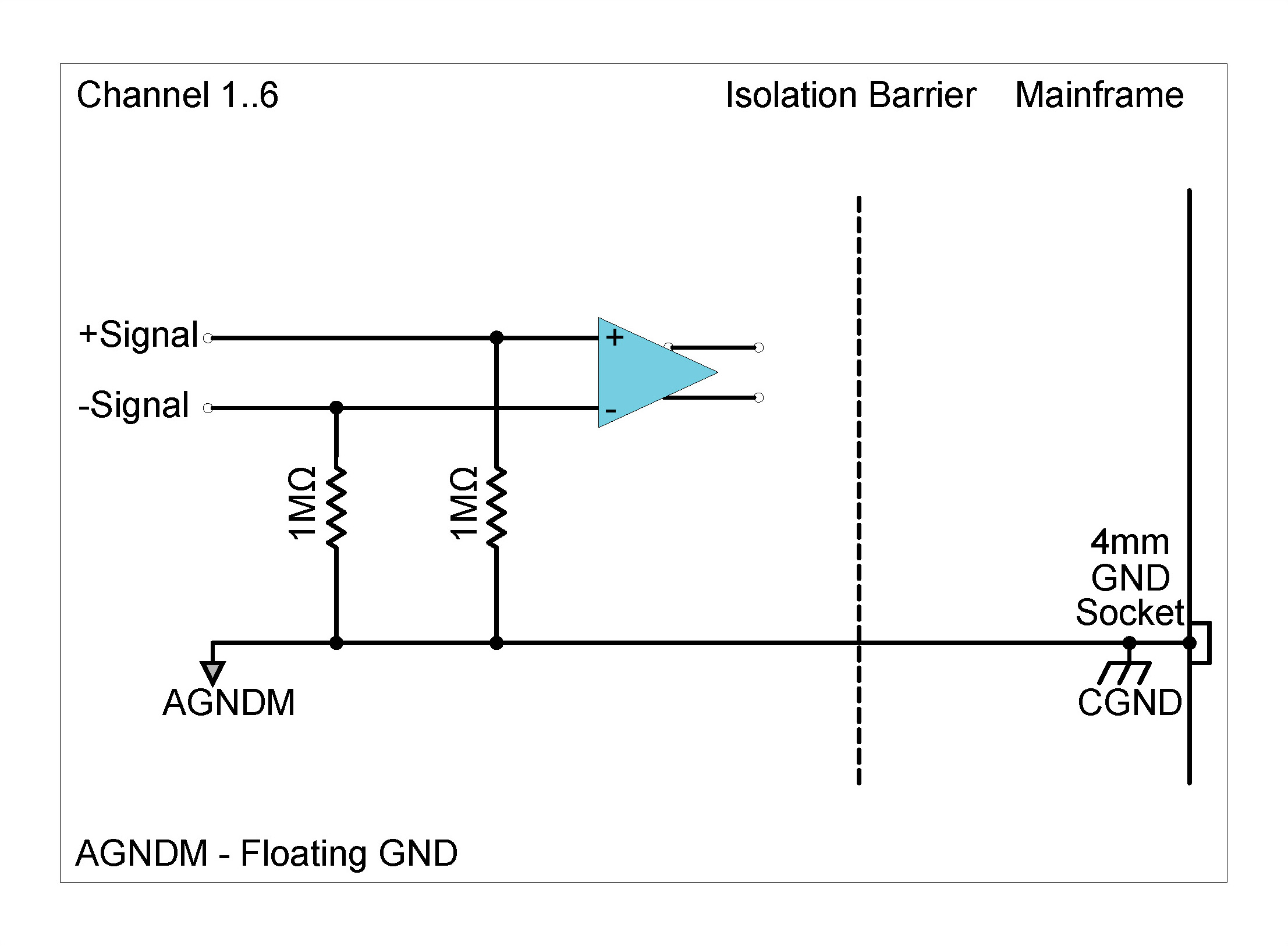

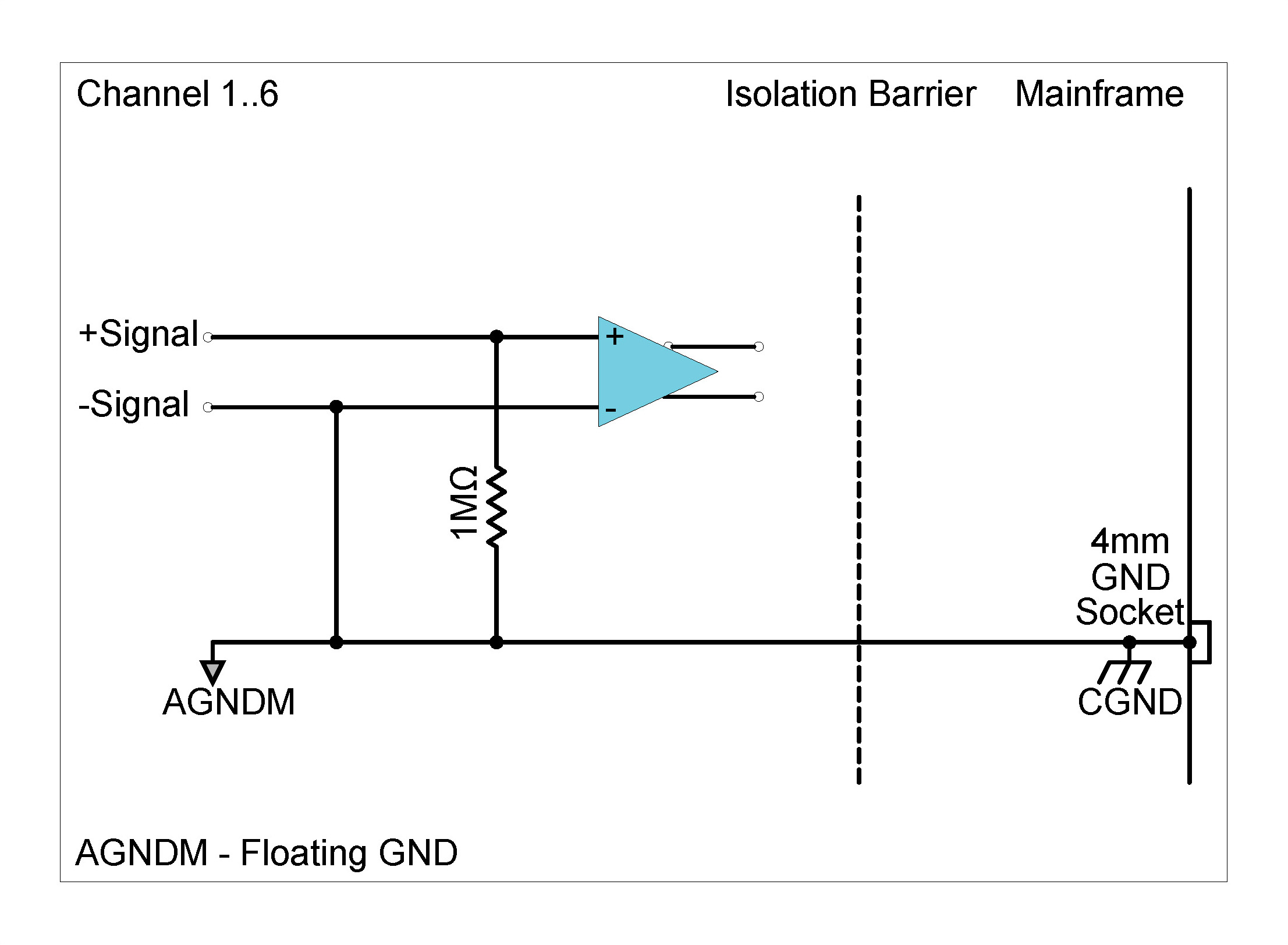

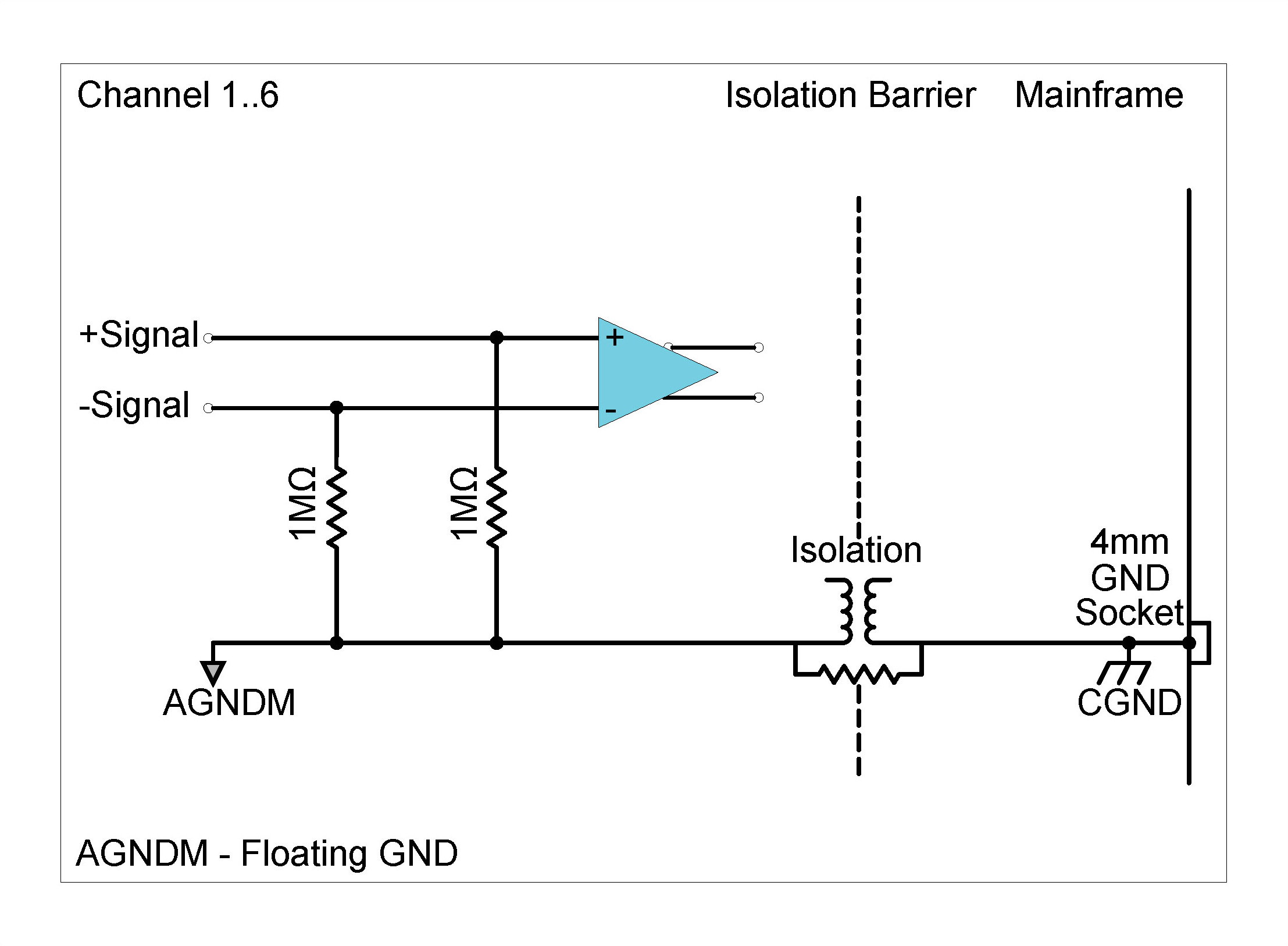

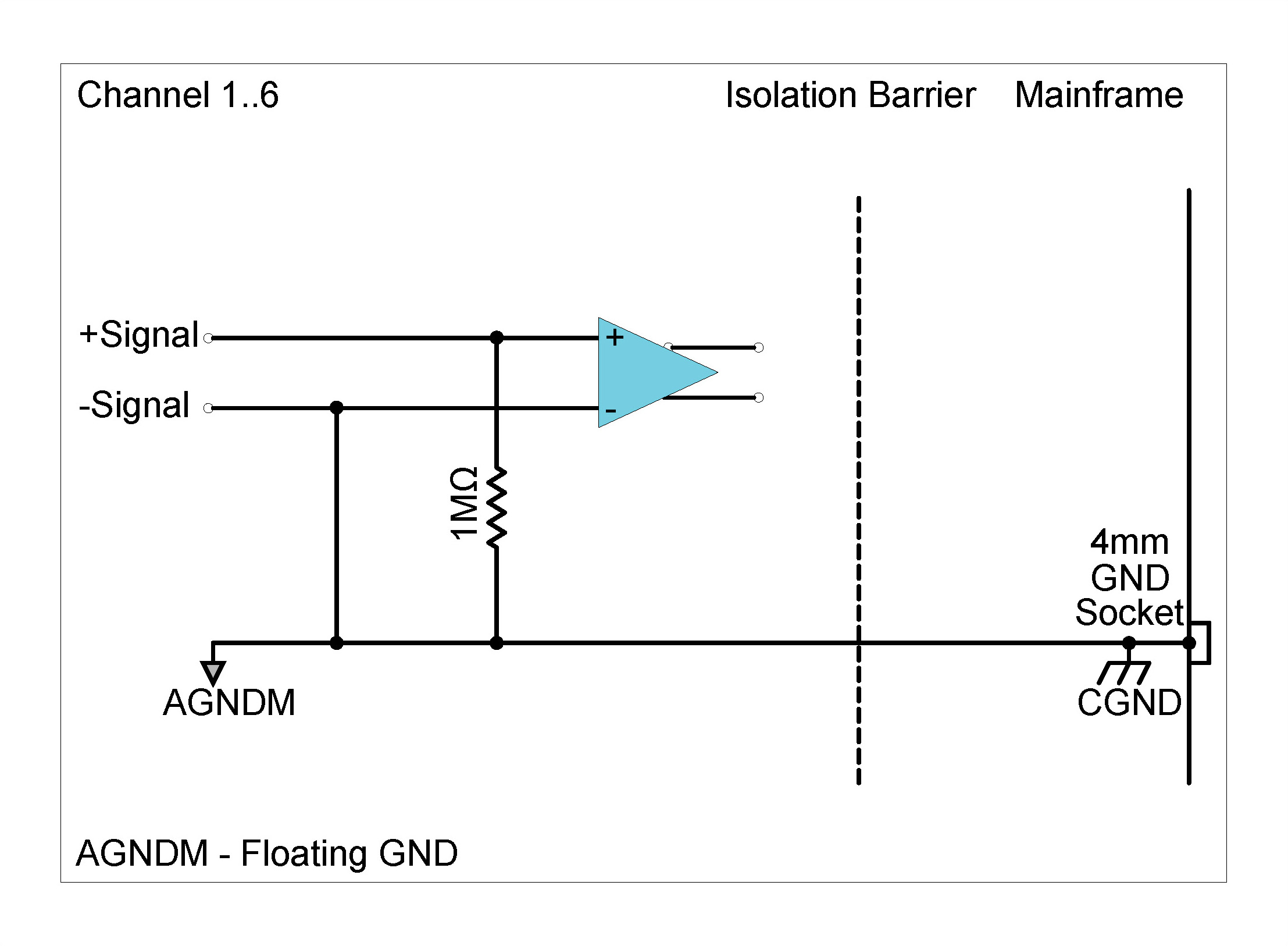

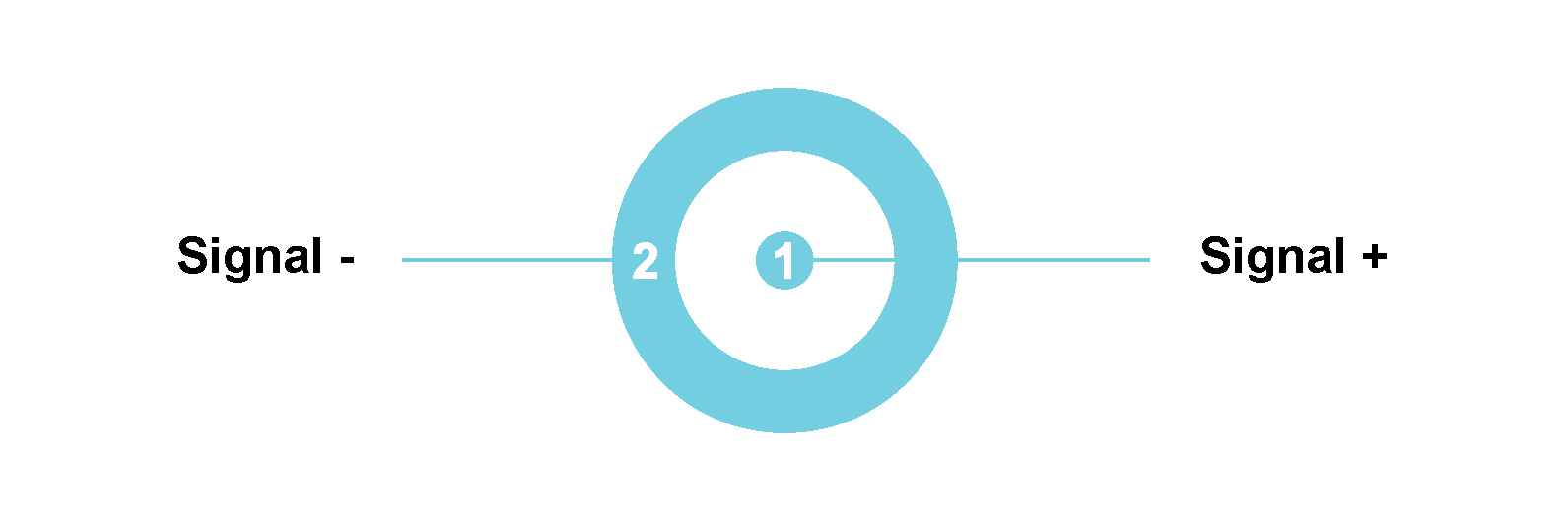

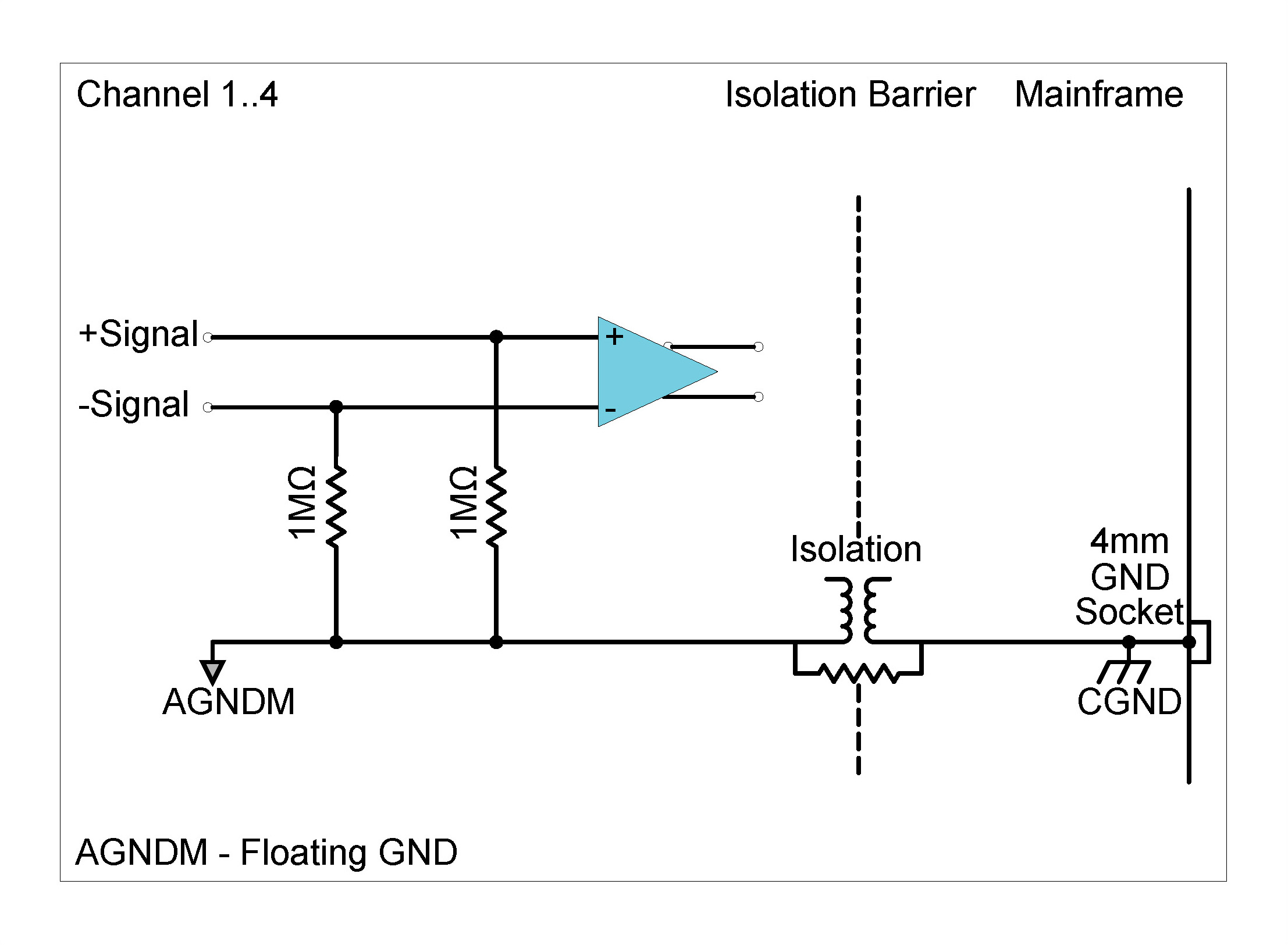

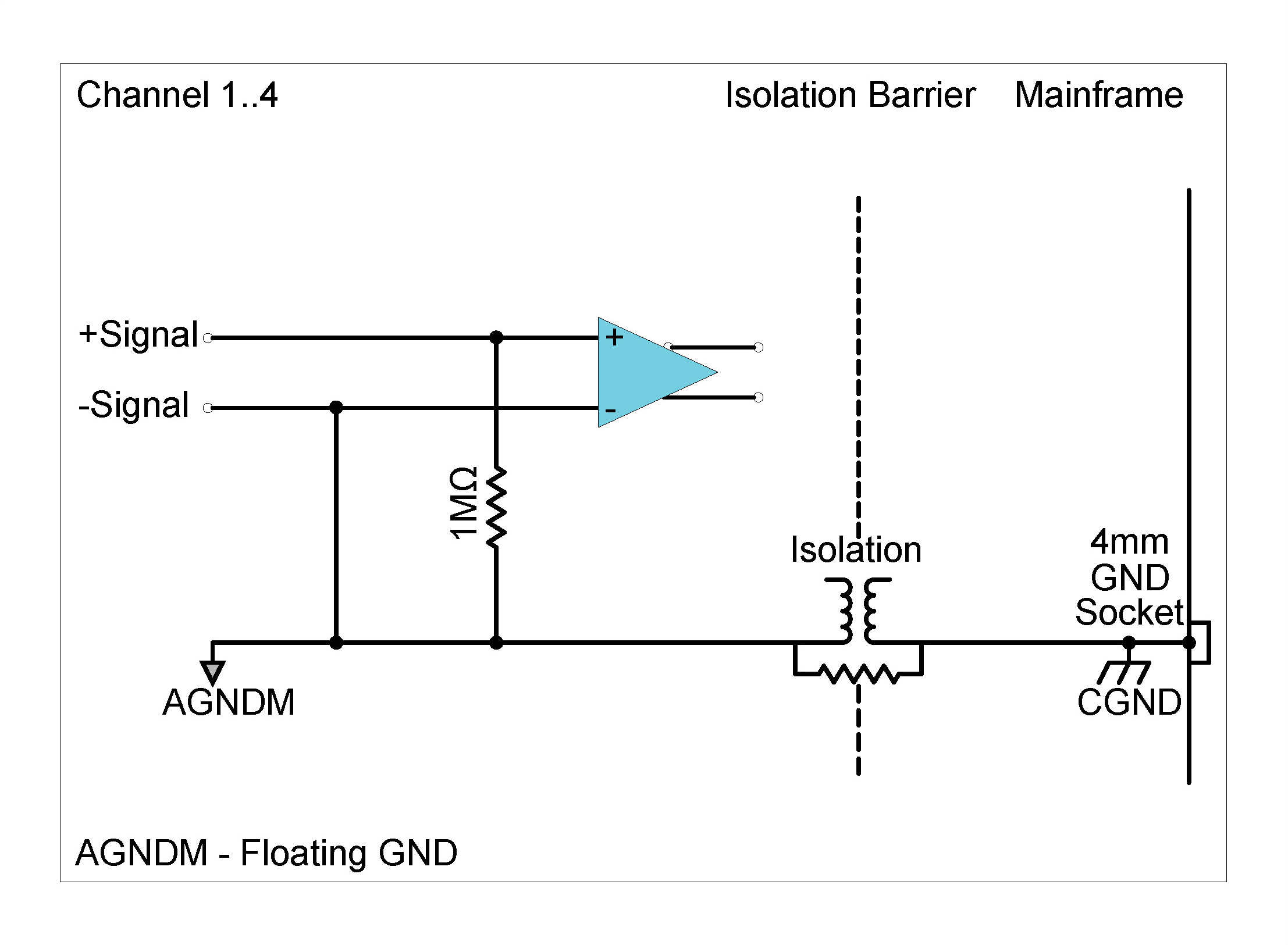

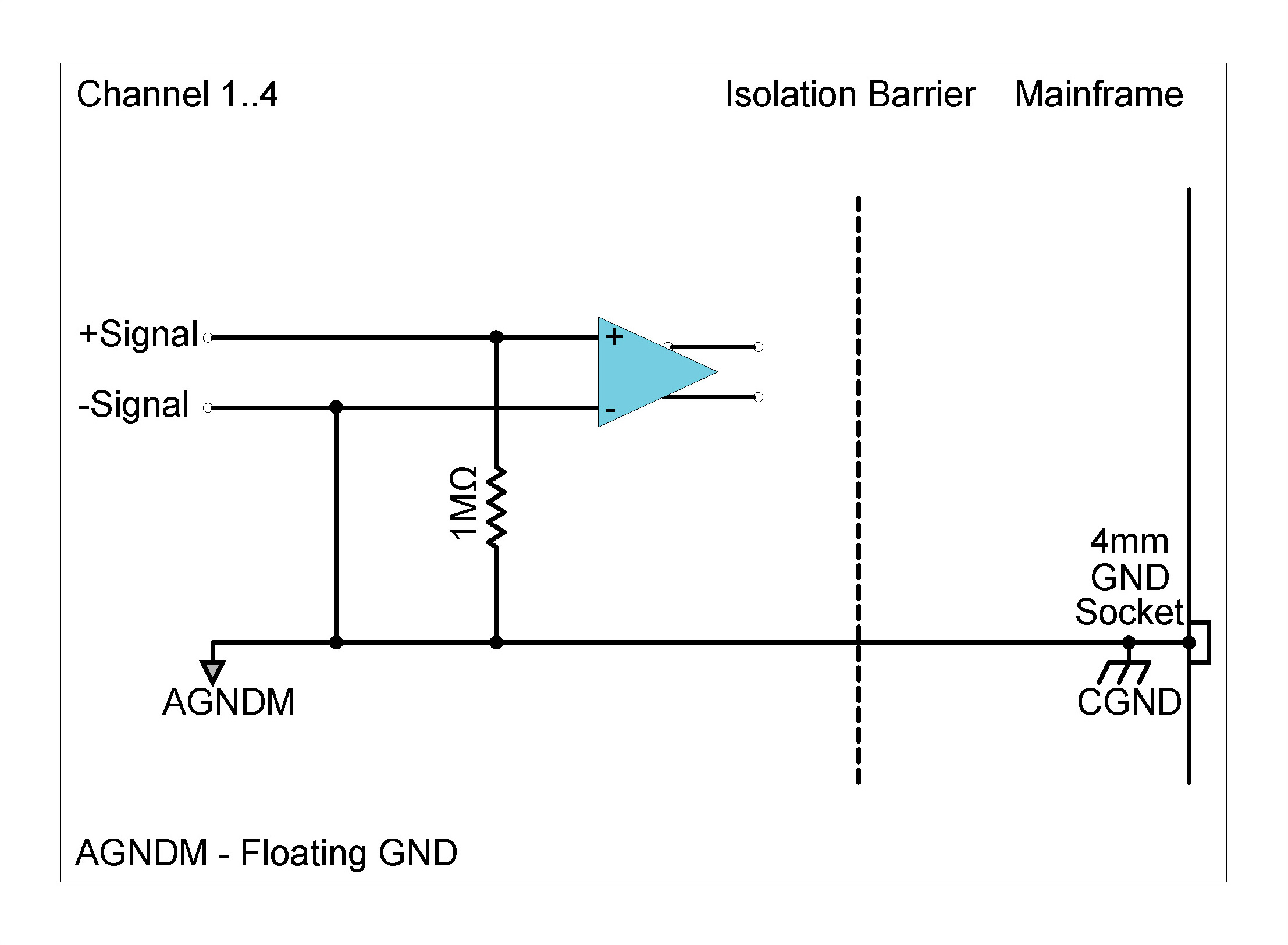

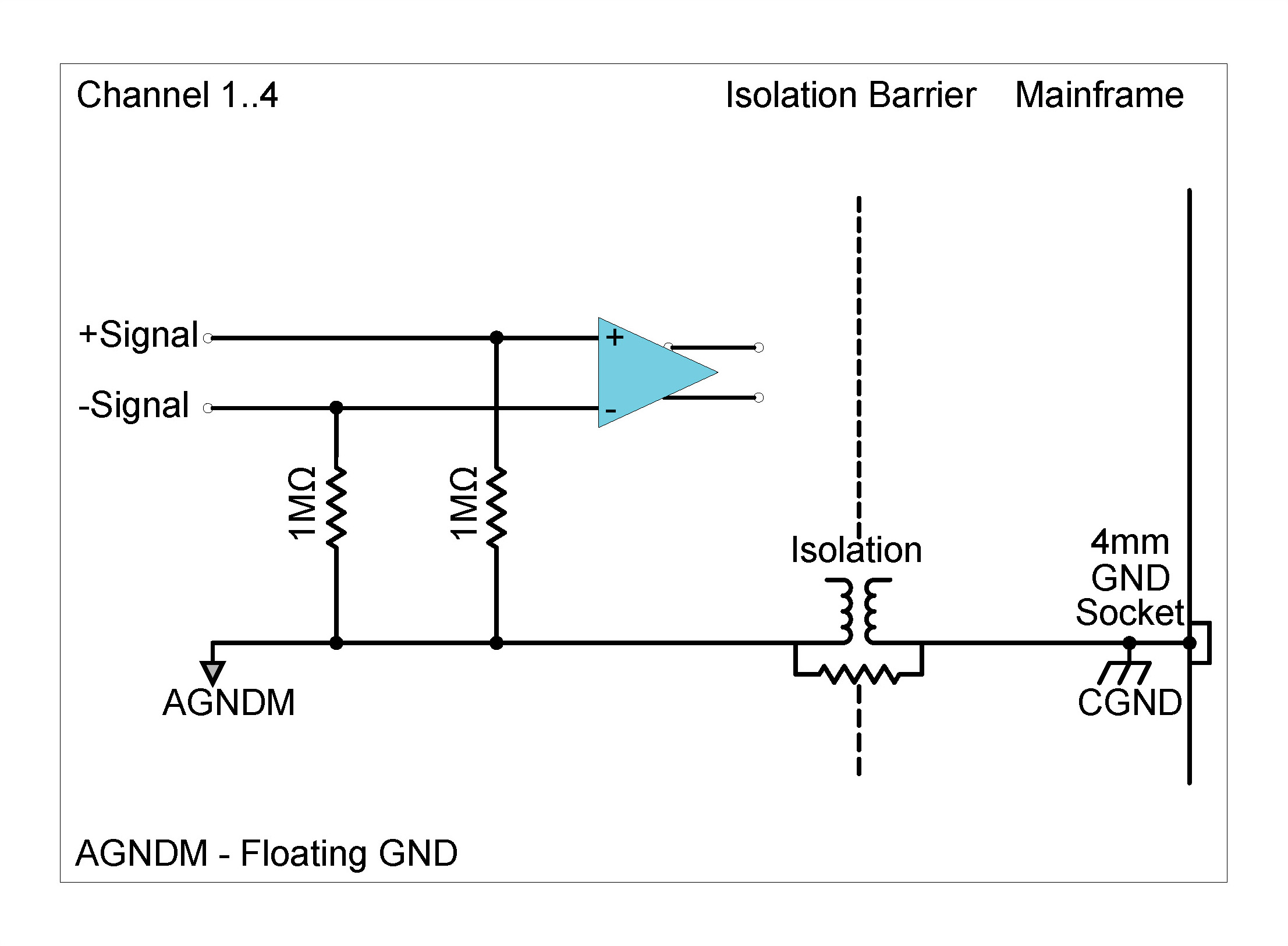

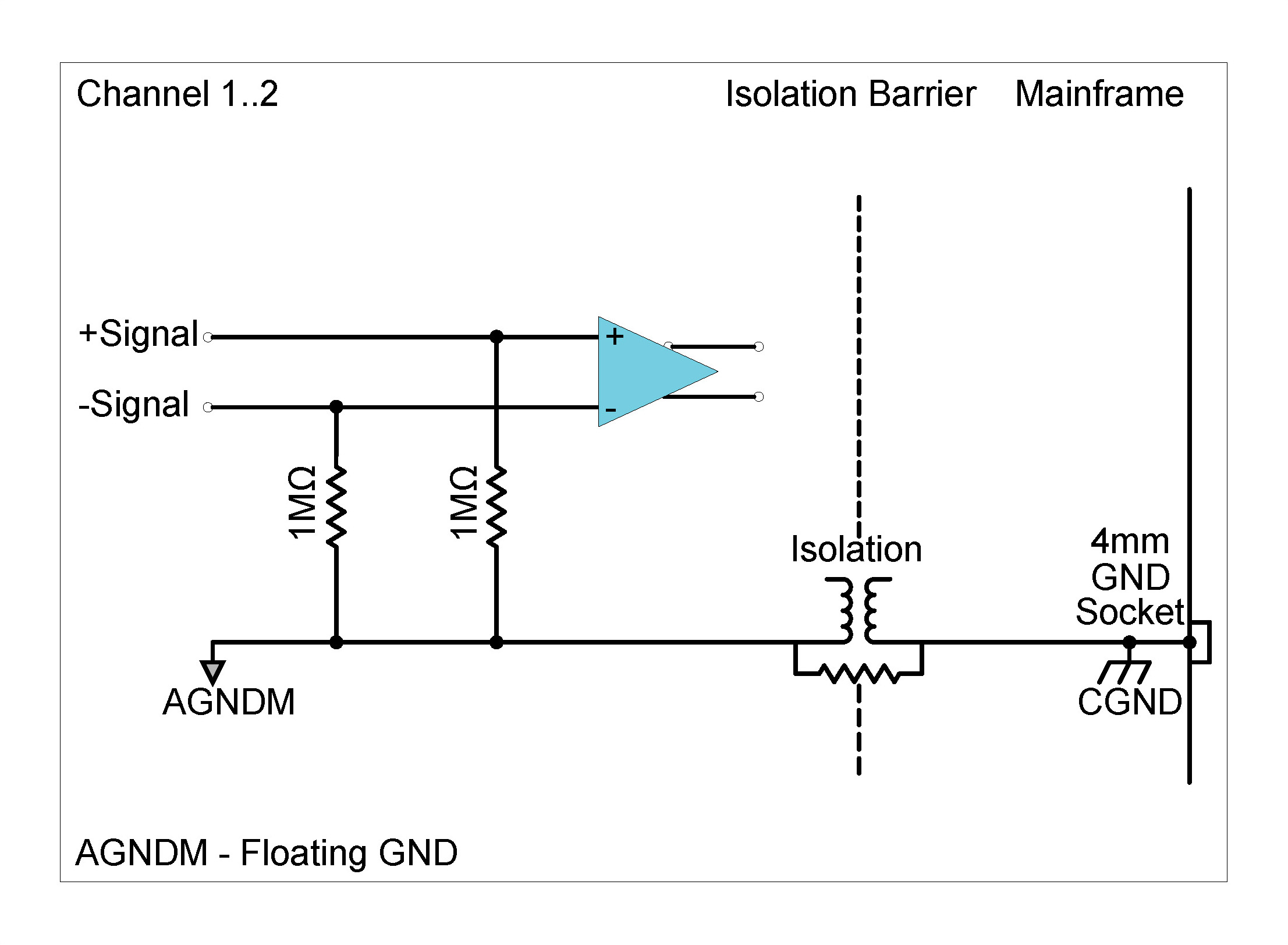

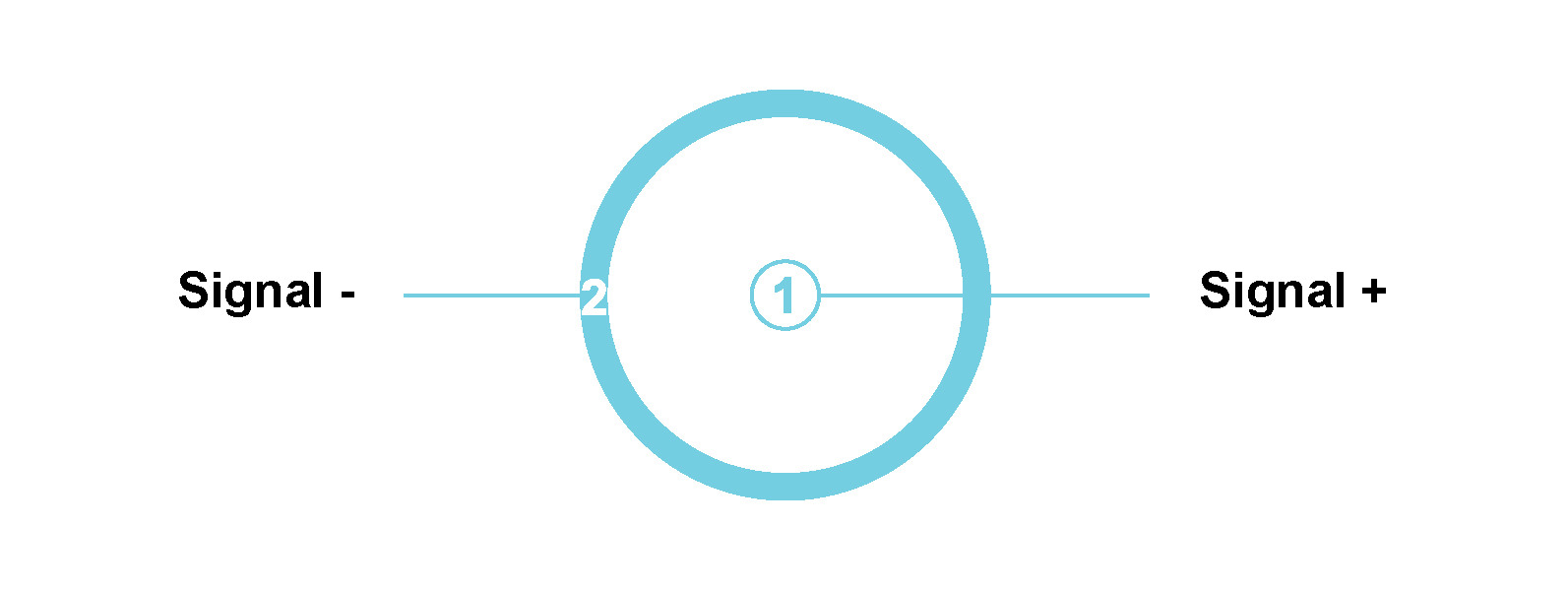

| Input Biasing Settings | Differential Float (Balanced Float) | Both the positive and negative signal inputs are connected through 1 MΩ to floating ground | |||

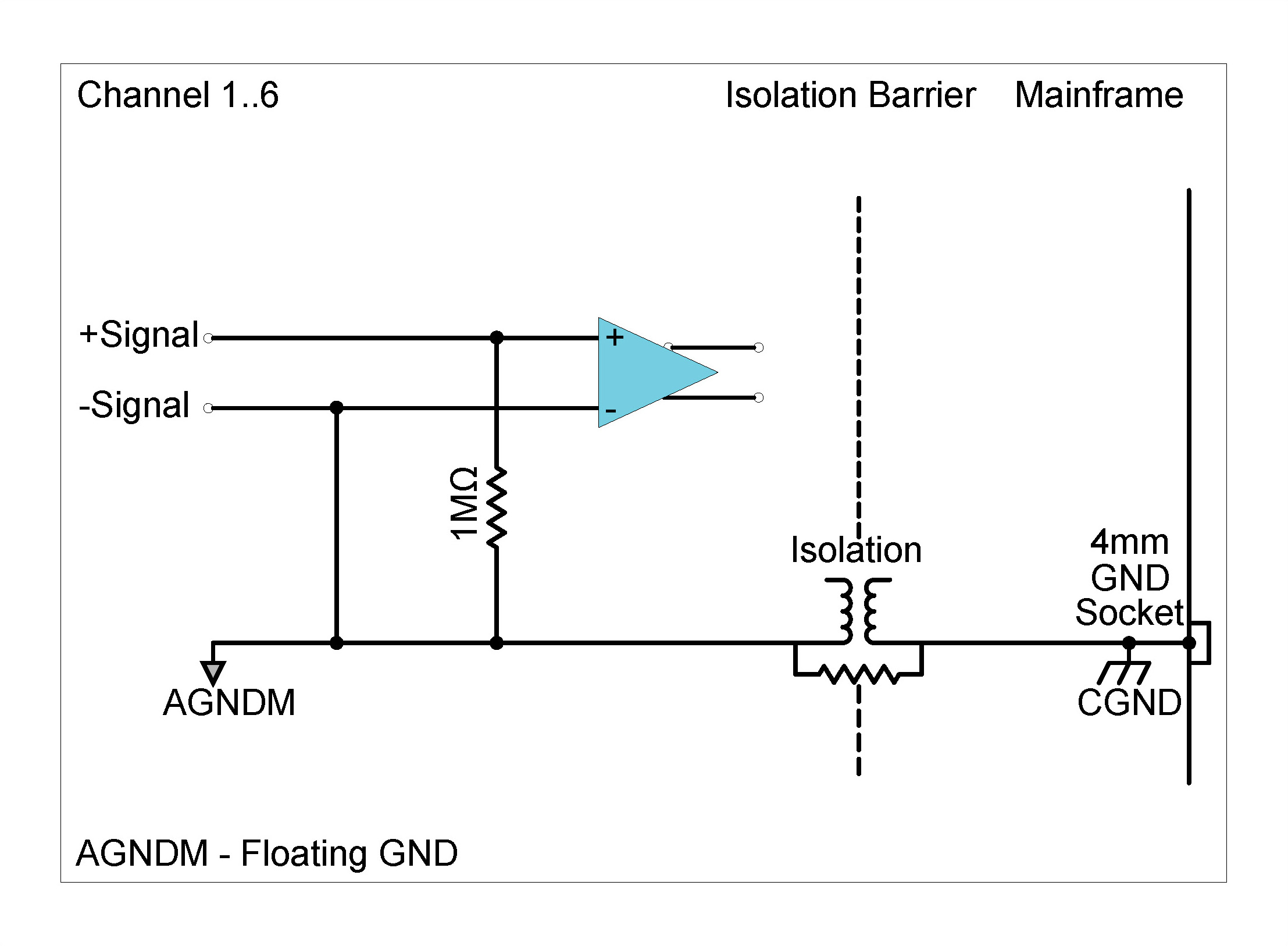

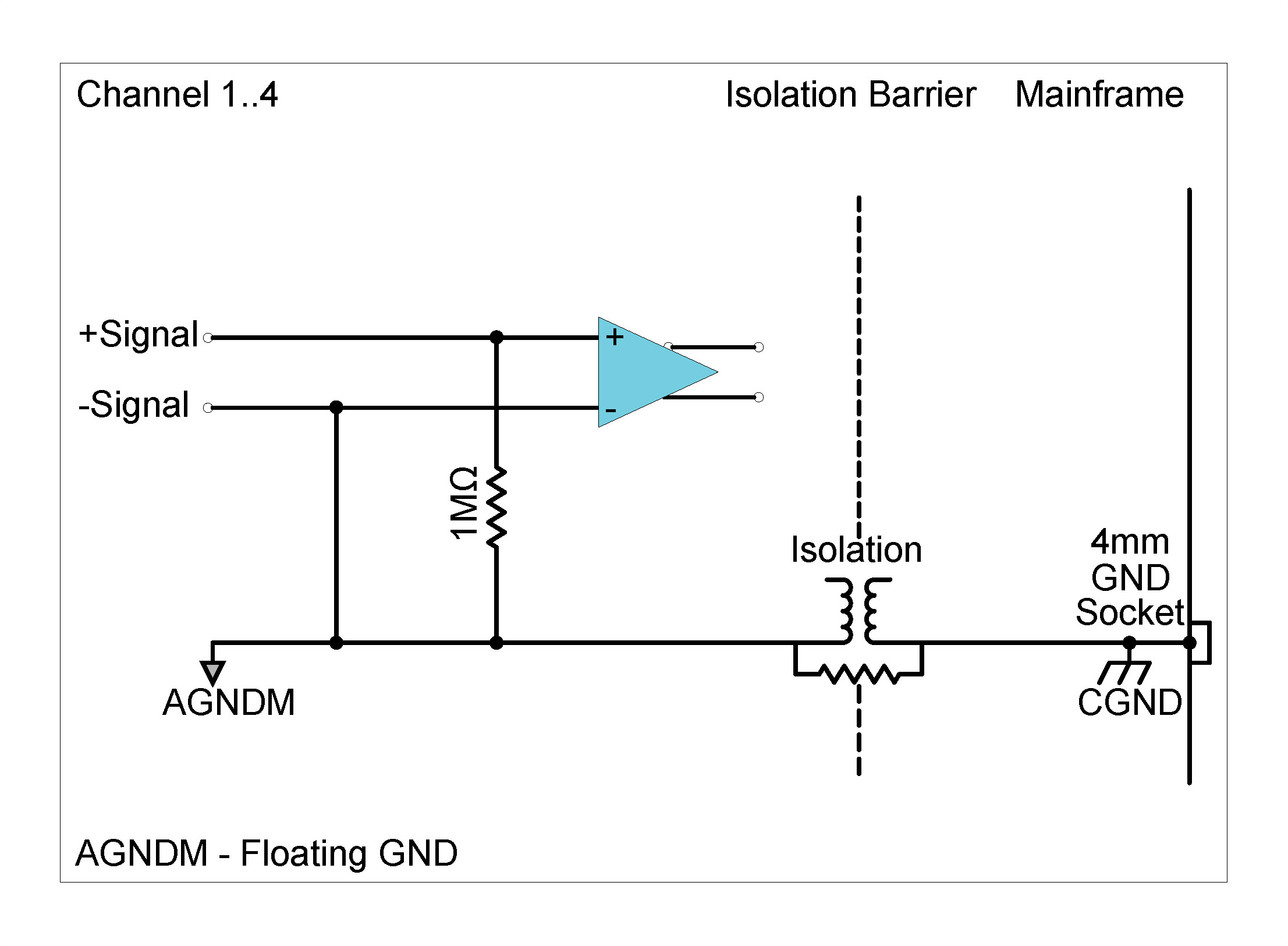

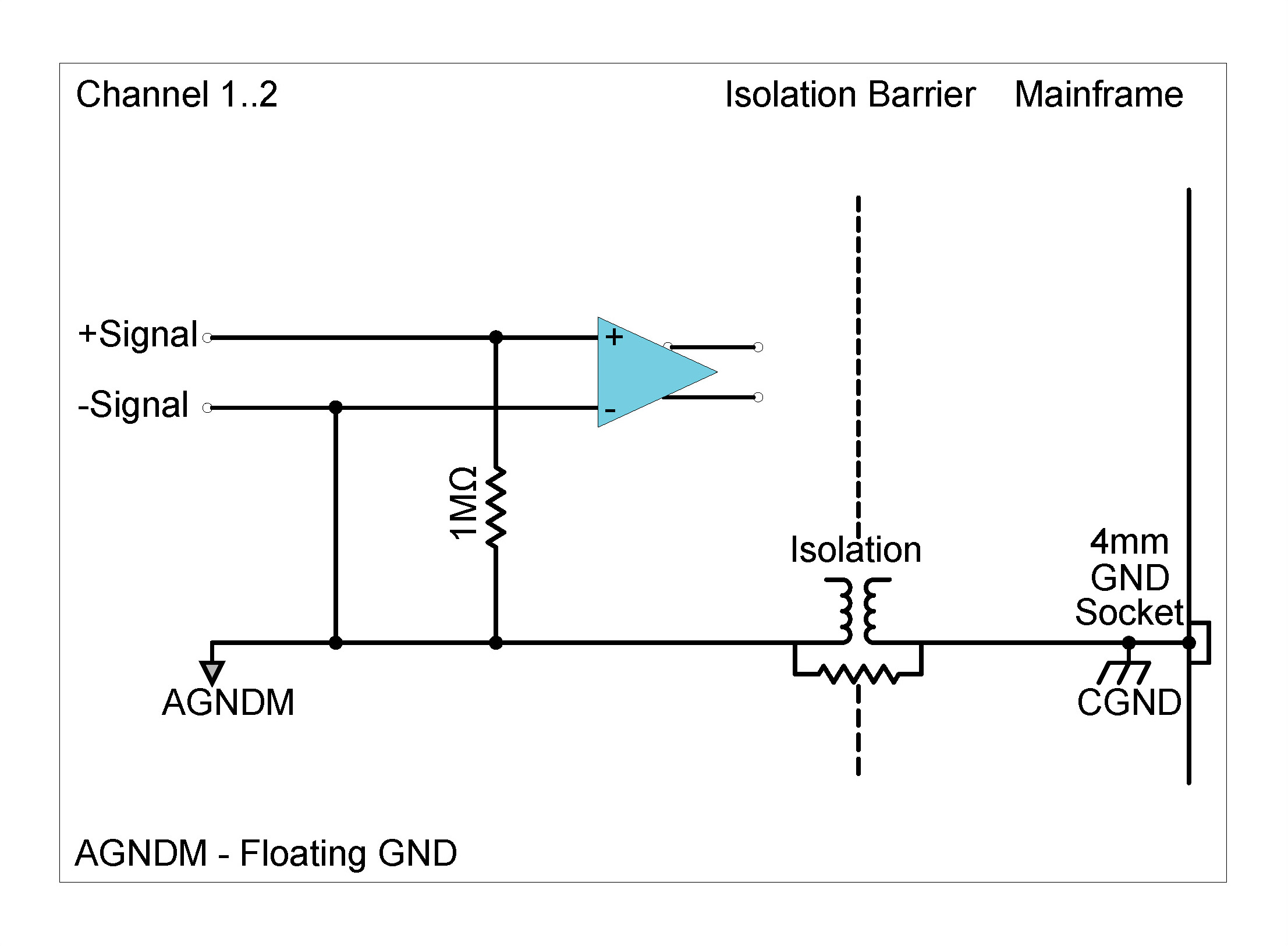

| Single-Ended Float (Unbalanced Float) | Positive signal input connected through 1 MΩ to floating ground; Negative signal input connected to floating ground | ||||

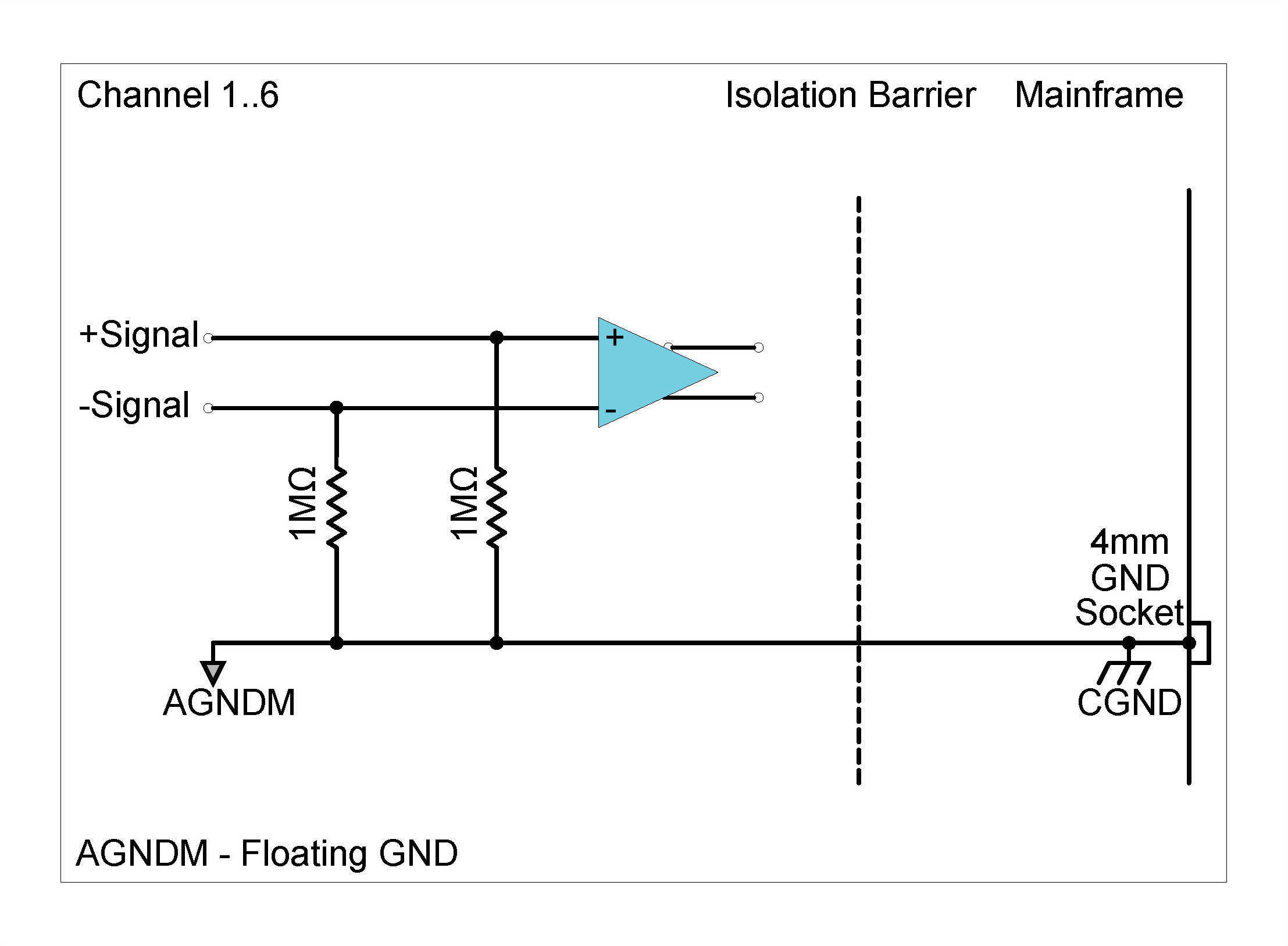

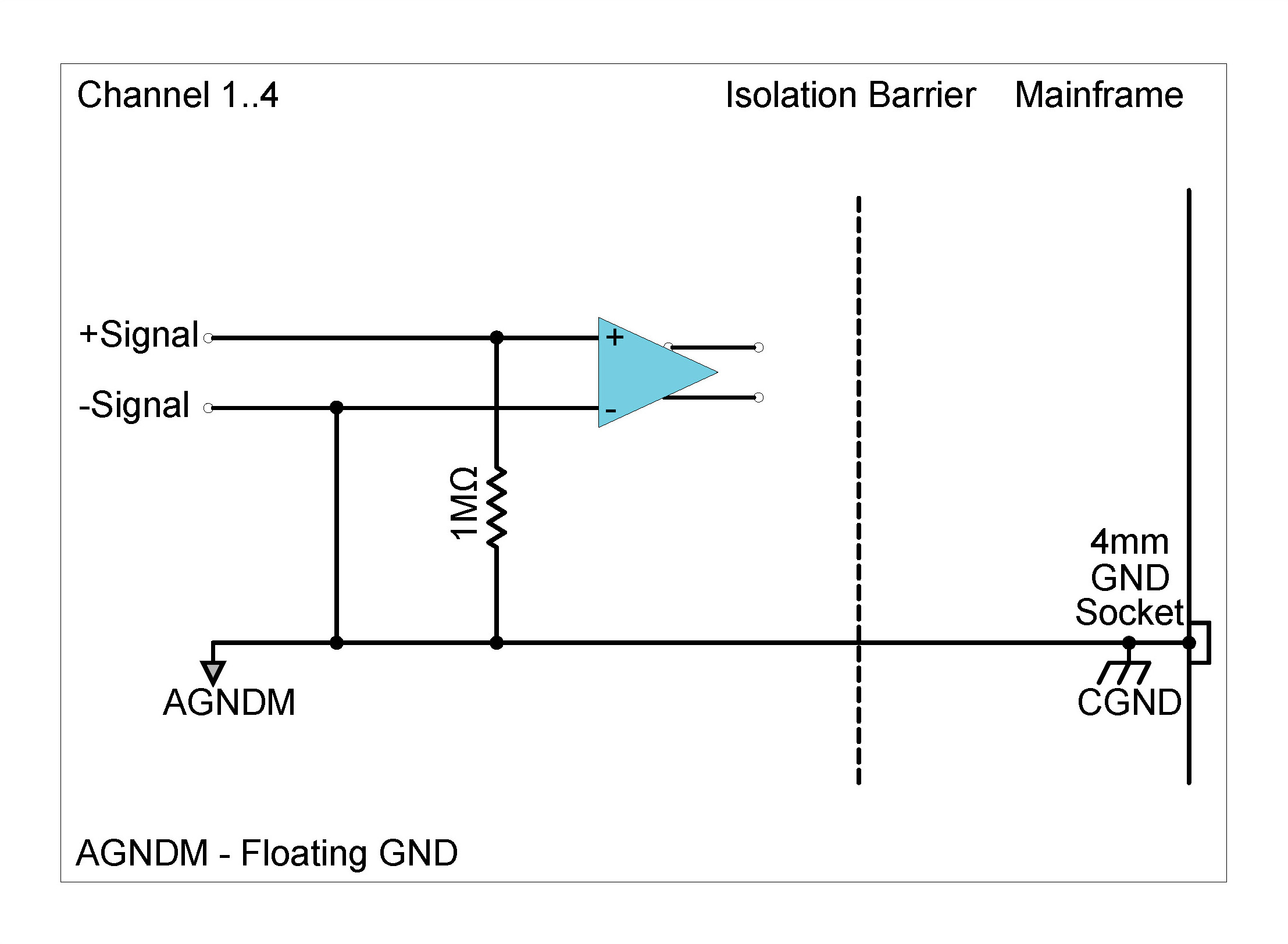

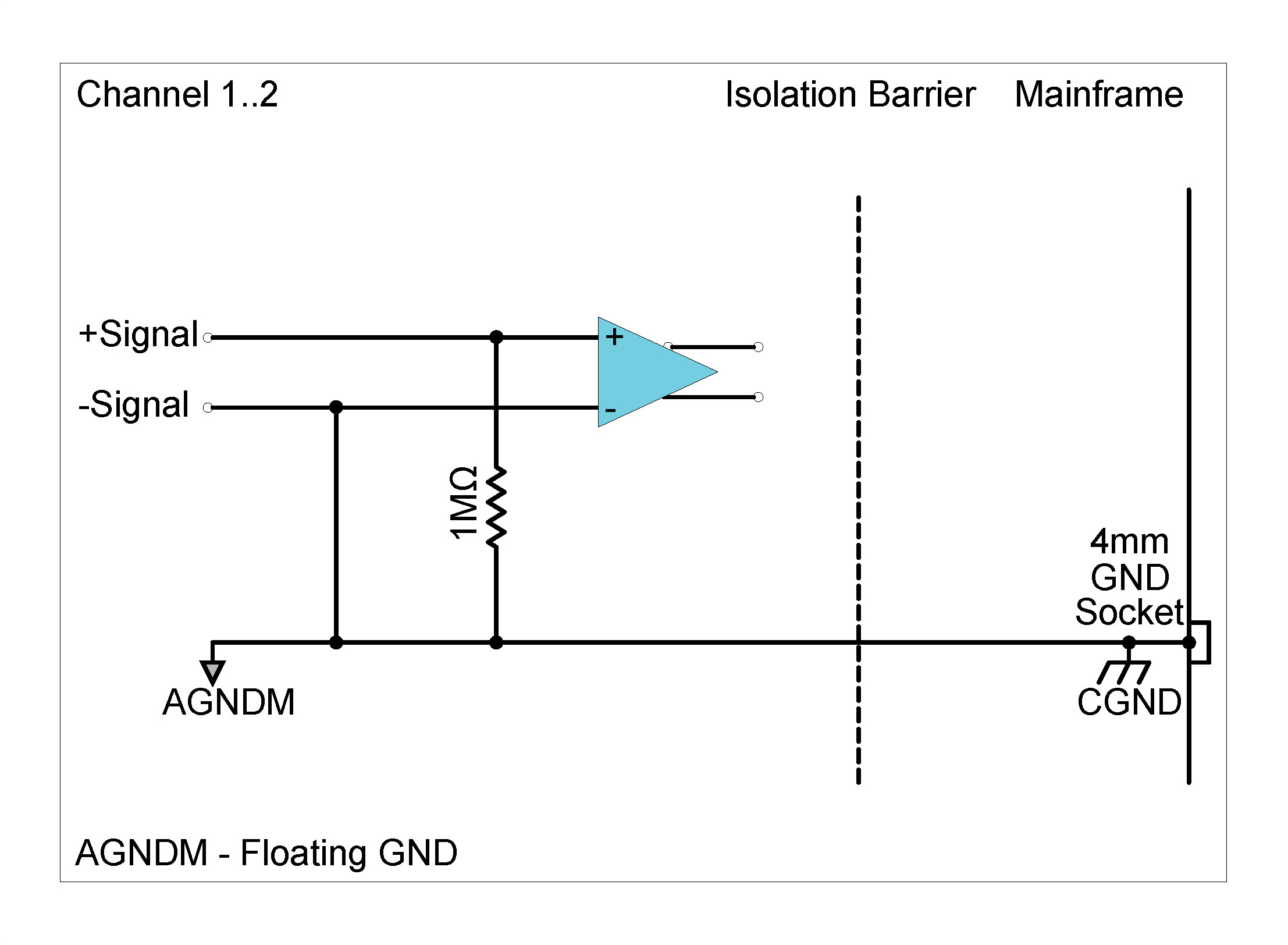

| Single-Ended GND (Unbalanced GND) | Positive signal input connected through 1 MΩ to ground; Negative signal input connected to ground | ||||

| Input Impedance | Differential | 2 MΩ ‖ 80 pF | |||

| Single-Ended | 1 MΩ ‖ 100 pF | ||||

|

Digital Low-Pass Filter Filter scales with sampling rate |

Passband | fs x 0.433 Hz | |||

| Stopband | fs x 0.499 Hz | ||||

| Passband ripple | ±0.005 dB | ||||

| Stopband attenuation | 105 dB | ||||

|

Phase Accuracy Channels in similar range |

Typical1 | <0.2° at 10 kHz> | |||

ICS42 Specifications

[1] Measured in 10 V range at 102.4 kSa/s

ICS42 Specifications continue

| DC Voltage Accuracy | Input Range (Peak) | Reading + % Range | ||

| ±100 mV | 0.200 % + 0.200 % | |||

| ±1 V | 0.068 % + 0.020 % | |||

| ±10 V | 0.113 % + 0.015 % | |||

|

Noise Input terminated by 50 Ω resistor |

Input Range (Peak) | Guaranteed | Typical | |

| 10 Hz to 22 kHz | ±100 mV | < 2.6 µVrms | < 2.2 µVrms | |

| 10 Hz to 44.3 kHz | < 4 µVrms | < 3 µVrms | ||

| 10 Hz to 22 kHz | ±1 V | < 9 µVrms | < 6 µVrms | |

| 10 Hz to 44.3 kHz | < 14 µVrms | < 10 µVrms | ||

| 10 Hz to 22 kHz | ±10 V | < 45 µVrms | < 40 µVrms | |

| 10 Hz to 44.3 kHz | < 113 µVrms | < 84 µVrms | ||

|

Dynamic Range2 Input terminated by 50 Ω resistor |

Input Range (Peak) | Typical | ||

| ±100 mV | > 120 dB | |||

| ±1 V | > 130 dB | |||

| ±10 V | > 130 dB | |||

|

Signal to Noise Ratio Input terminated by 50 Ω resistor |

Input Range (Peak) | Typical | ||

| ±10 V | > 104 dB; 22 kHz bandwidth | |||

|

Amplitude Flatness Relative to 1 kHz Measured up to 0.39 x fs |

Sampling Rate (fs) | Input Range (Peak) | Attenuation (Input signal level 100 % of full range) | |

| 51.2 kSa/s | ±100 mV | − 0.06 dB | ||

| 102.4 kSa/s | − 0.10 dB | |||

| 51.2 kSa/s | ±1 V | − 0.04 dB | ||

| 102.4 kSa/s | − 0.05 dB | |||

| 51.2 kSa/s | ±10 V | − 0.03 dB | ||

| 102.4 kSa/s | − 0.04 dB | |||

| Crosstalk | Input Range (Peak) | Guaranteed | Typical | |

| ±100 mV | 113 dB | 118 dB | ||

| ±1 V | 110 dB | 115 dB | ||

| ±10 V | 102 dB | 107 dB | ||

ICS42 Specifications

2 Dynamic range calculated at sampling rate of 51.2 kSa/s,

with a 4096-point FFT.

Specification number: SP151000, Release 2.4. The Module settings and measurement conditions that were used during specification measurements are available on request.

Functionality per Channel

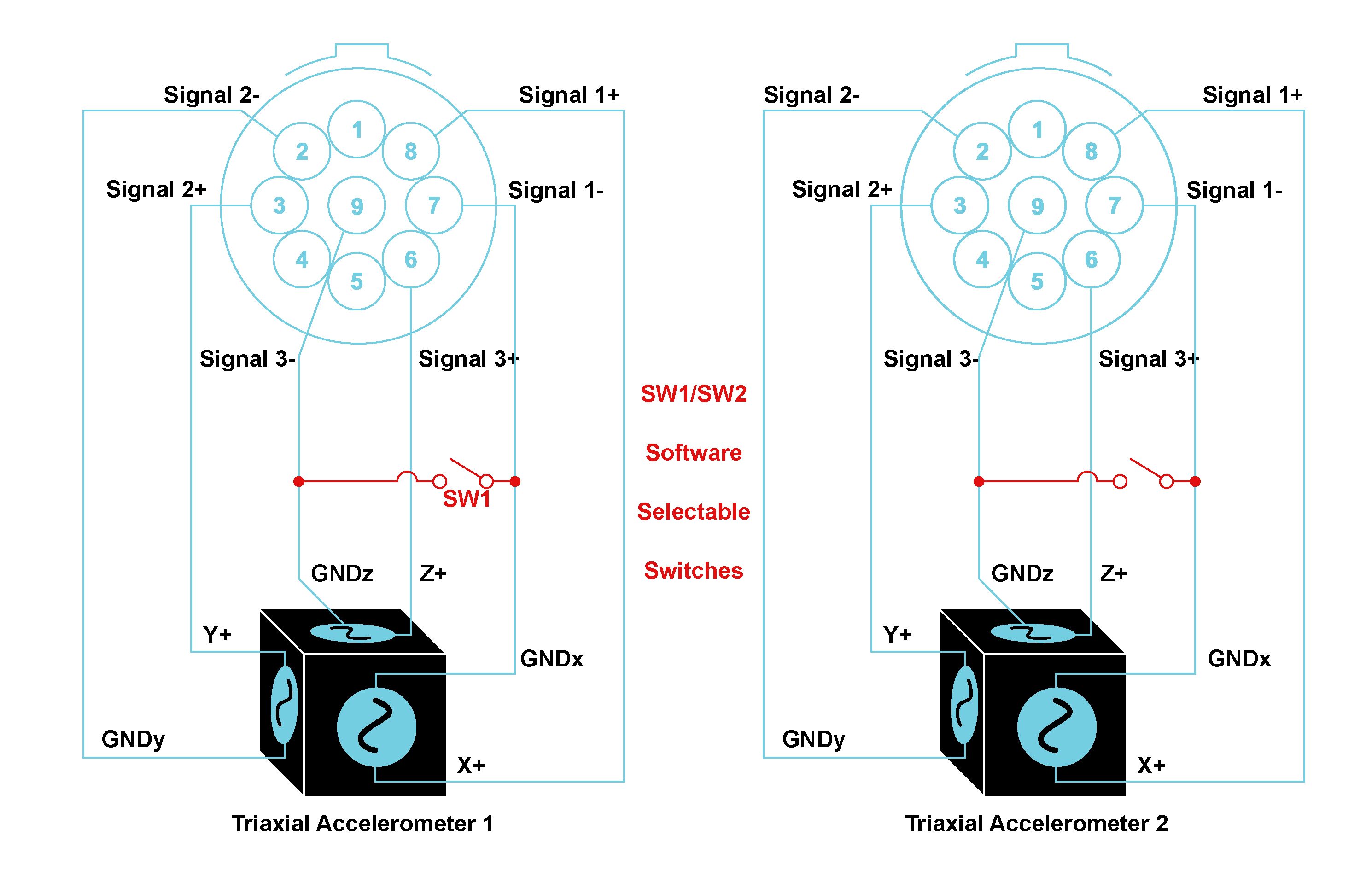

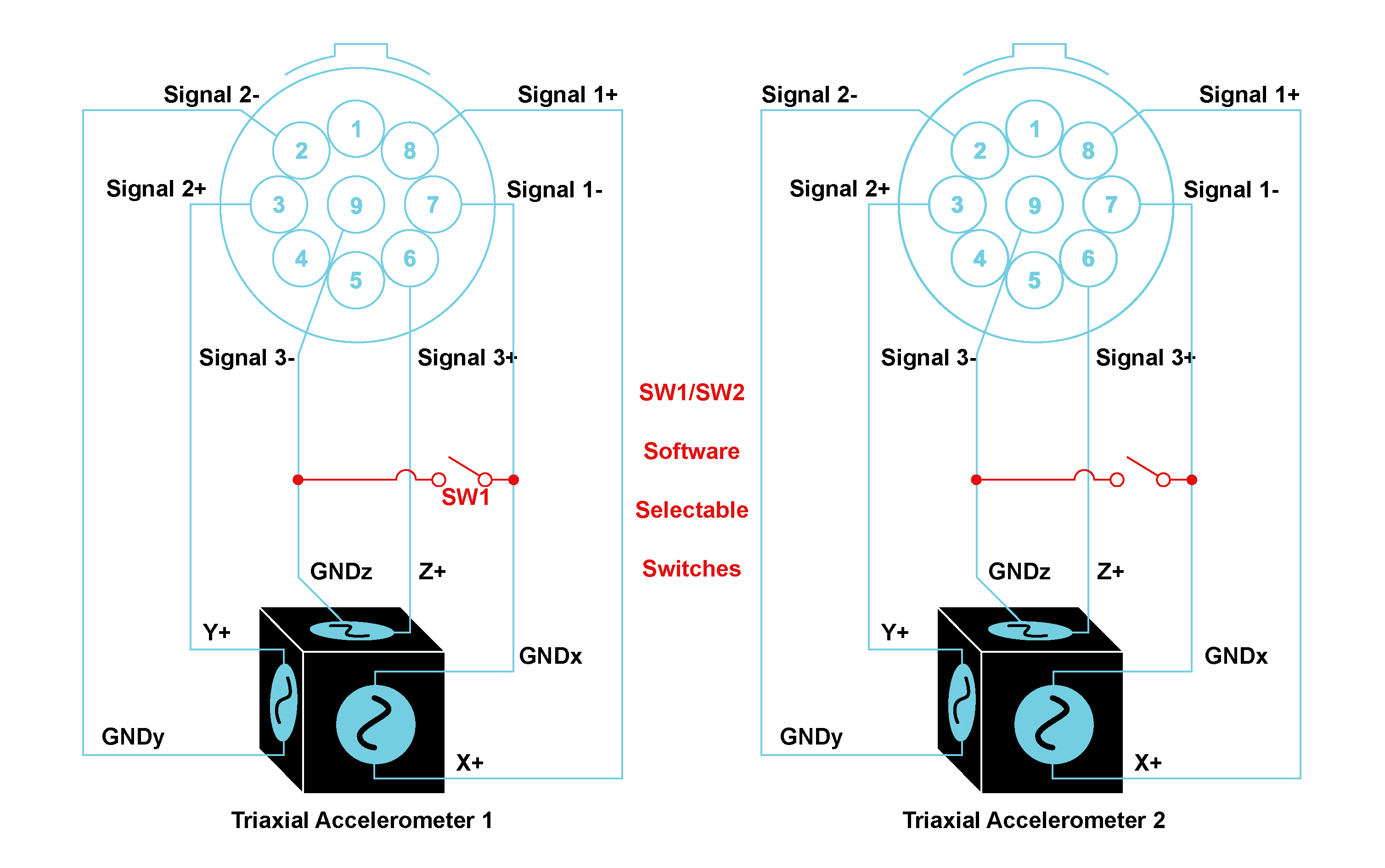

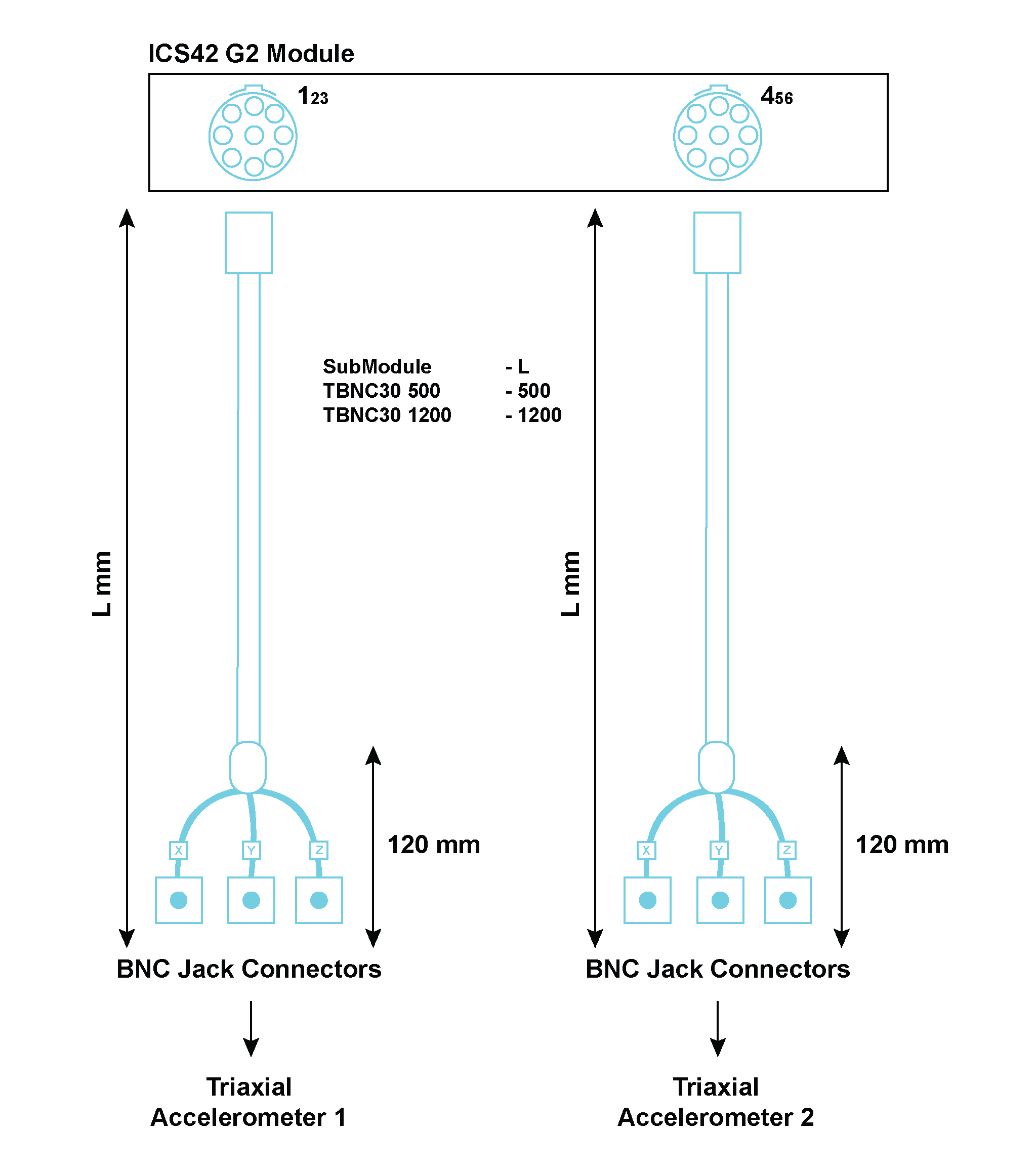

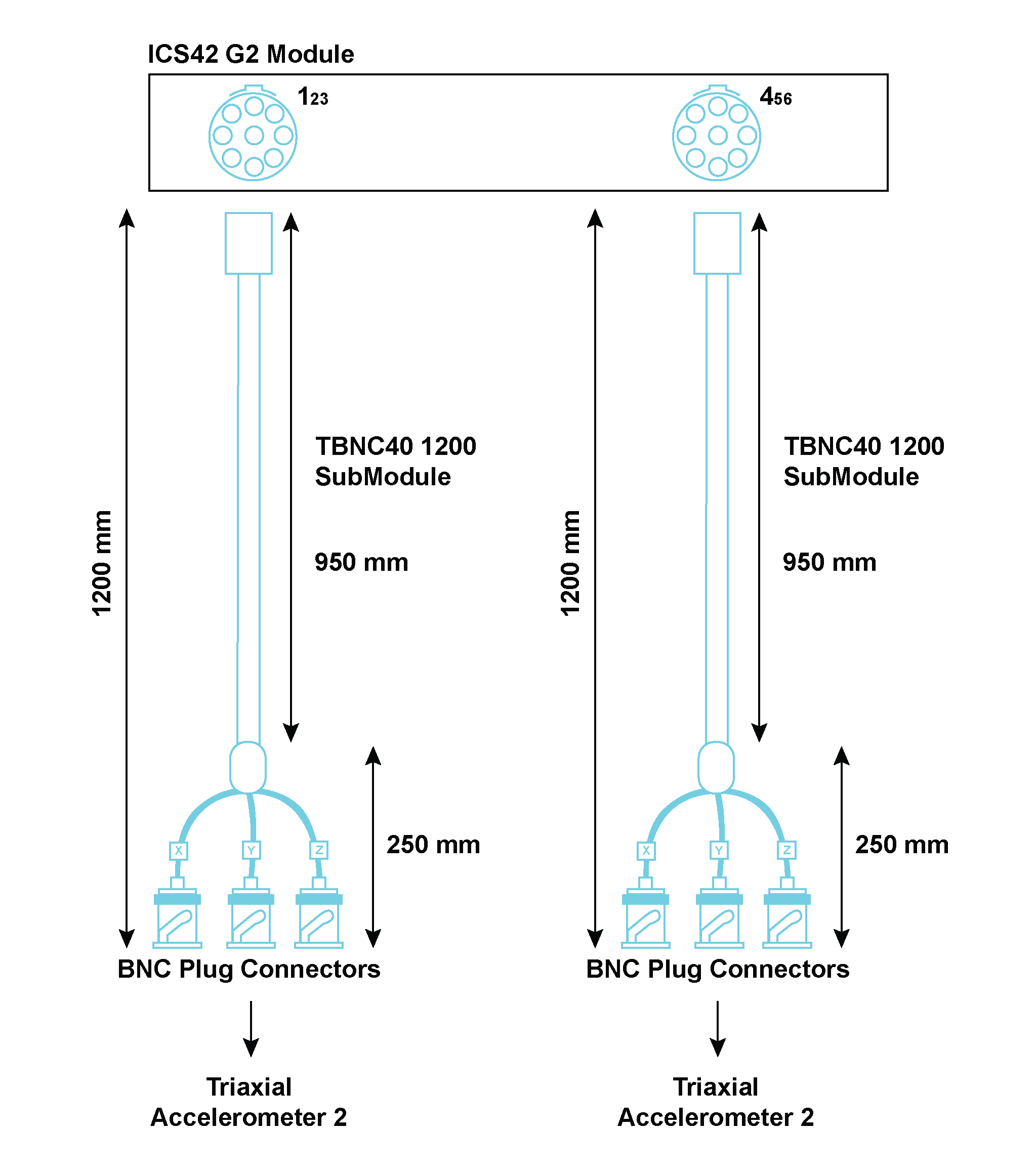

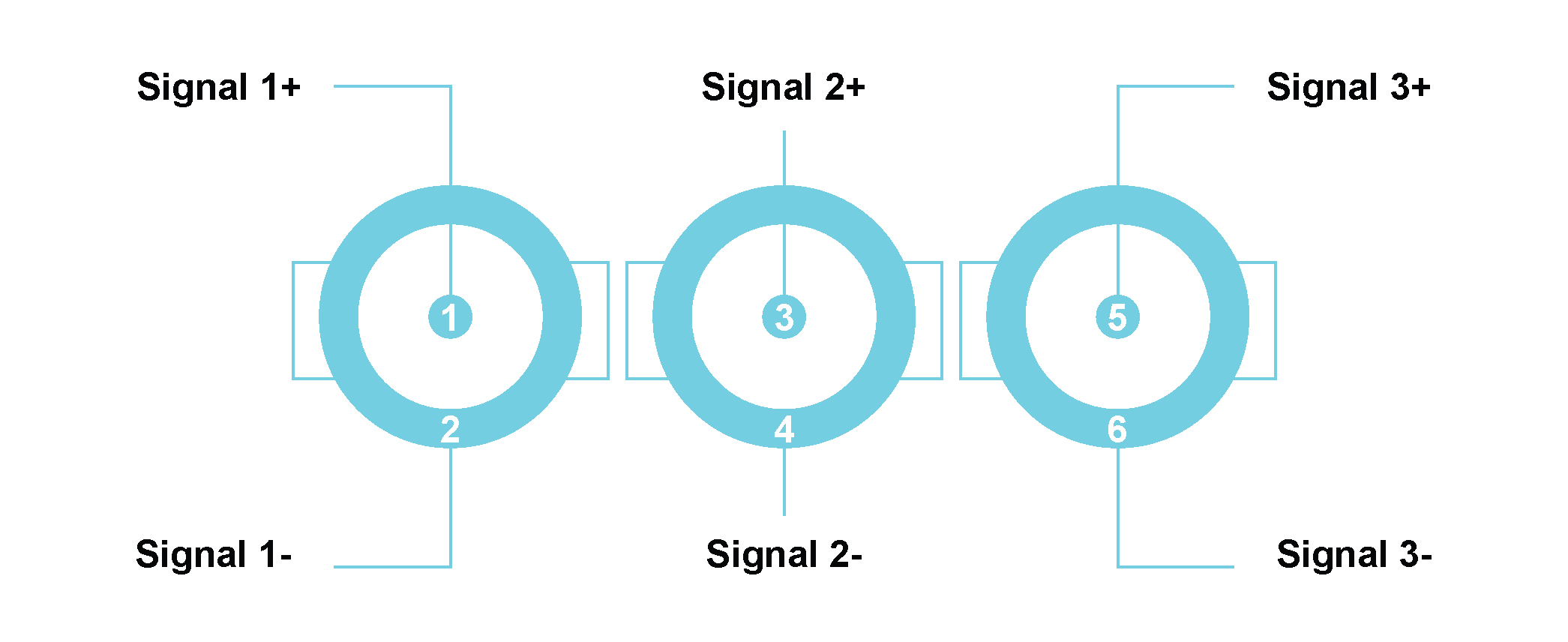

Accelerometer connections per Module

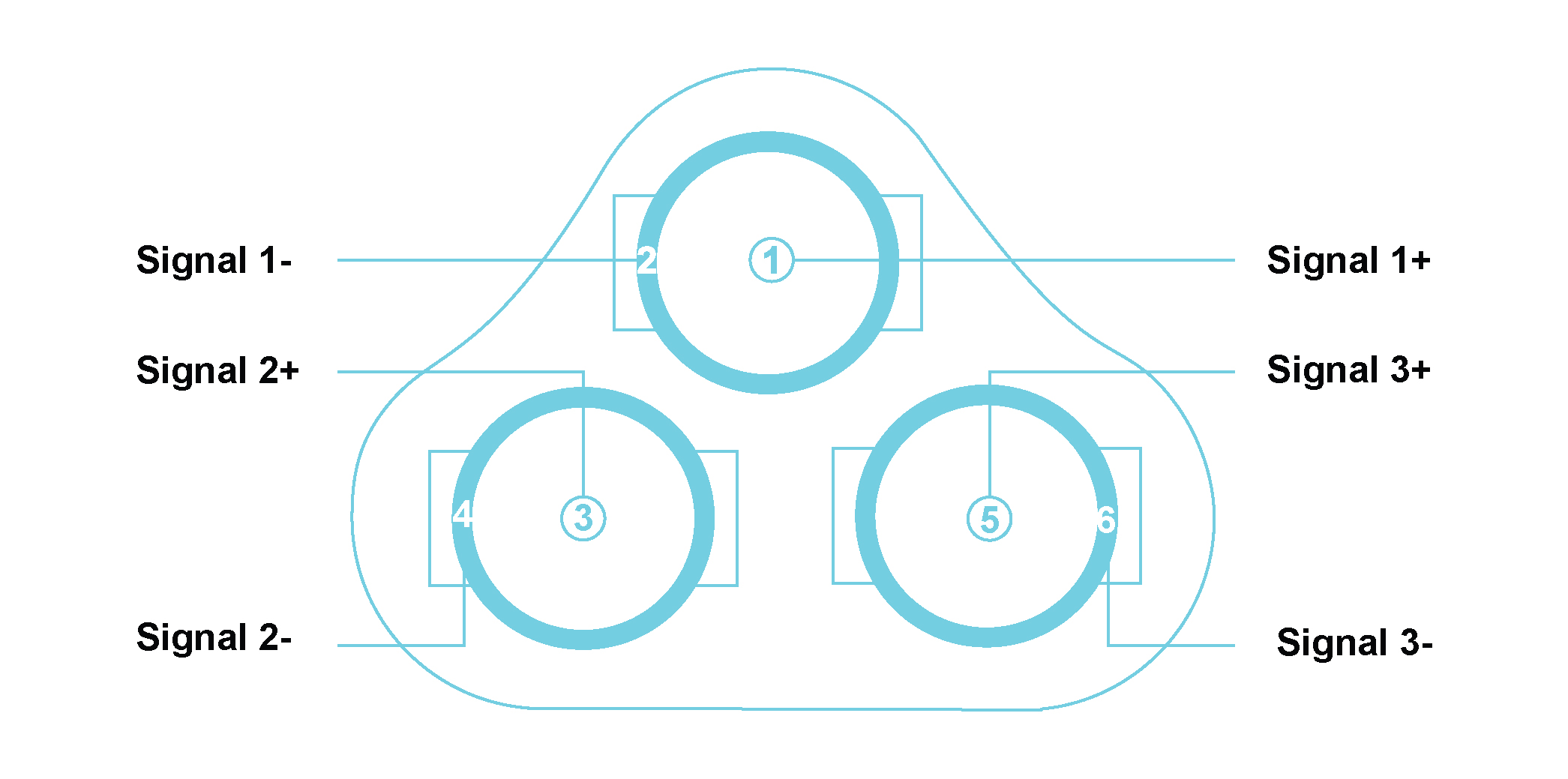

The ICS42 can accept inputs from single ICP® accelerometers as well as triaxial ICP® accelerometers. The connectors on the front panel are ideally designed to connect to two triaxial sensors per Module. The LEMO® 9-way EHG.0B connectors Module Pin Definition indicates where the signal connections of each X, Y and Z and the common return of the triaxial sensor can be connected.

Grounding options

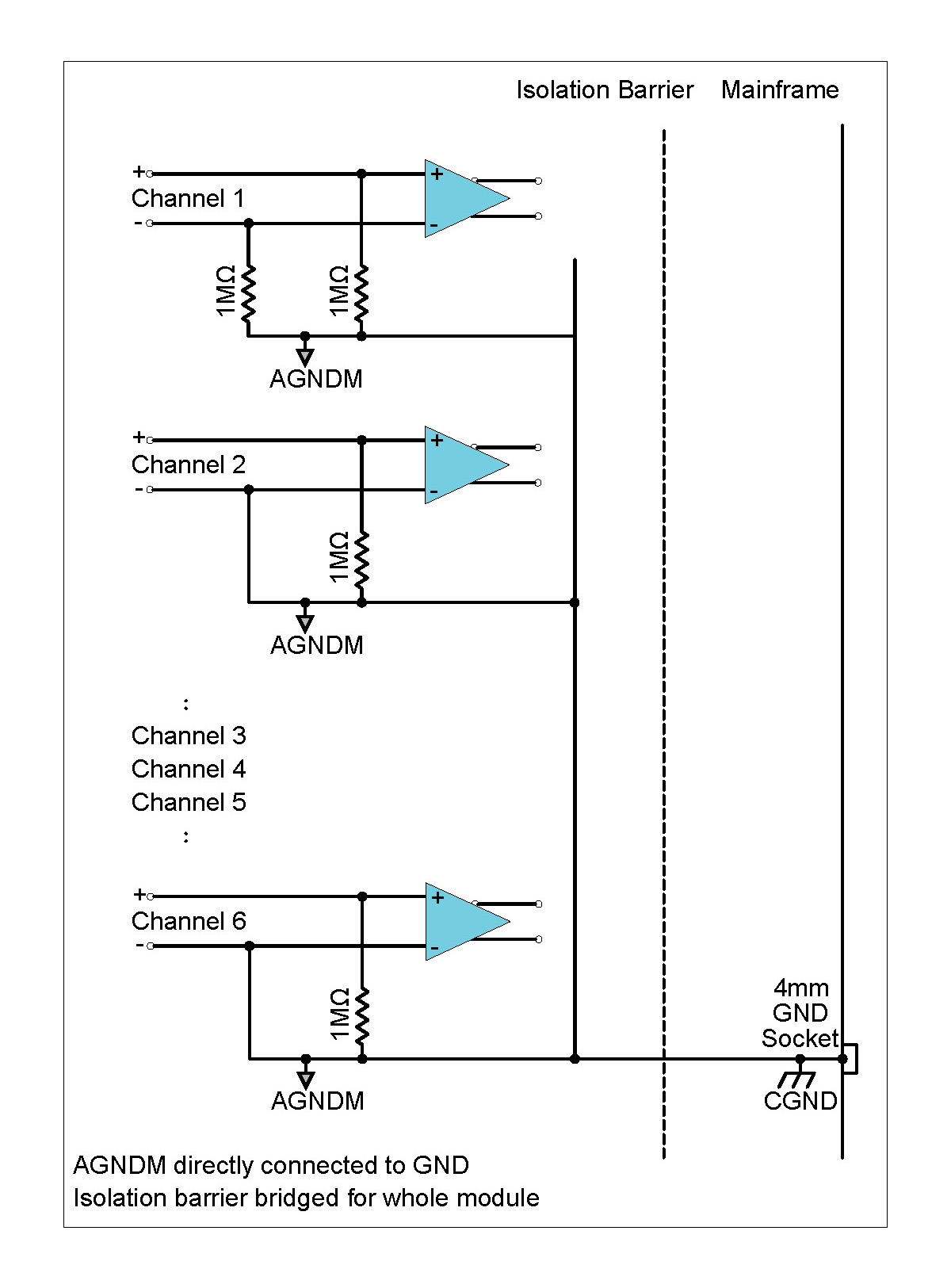

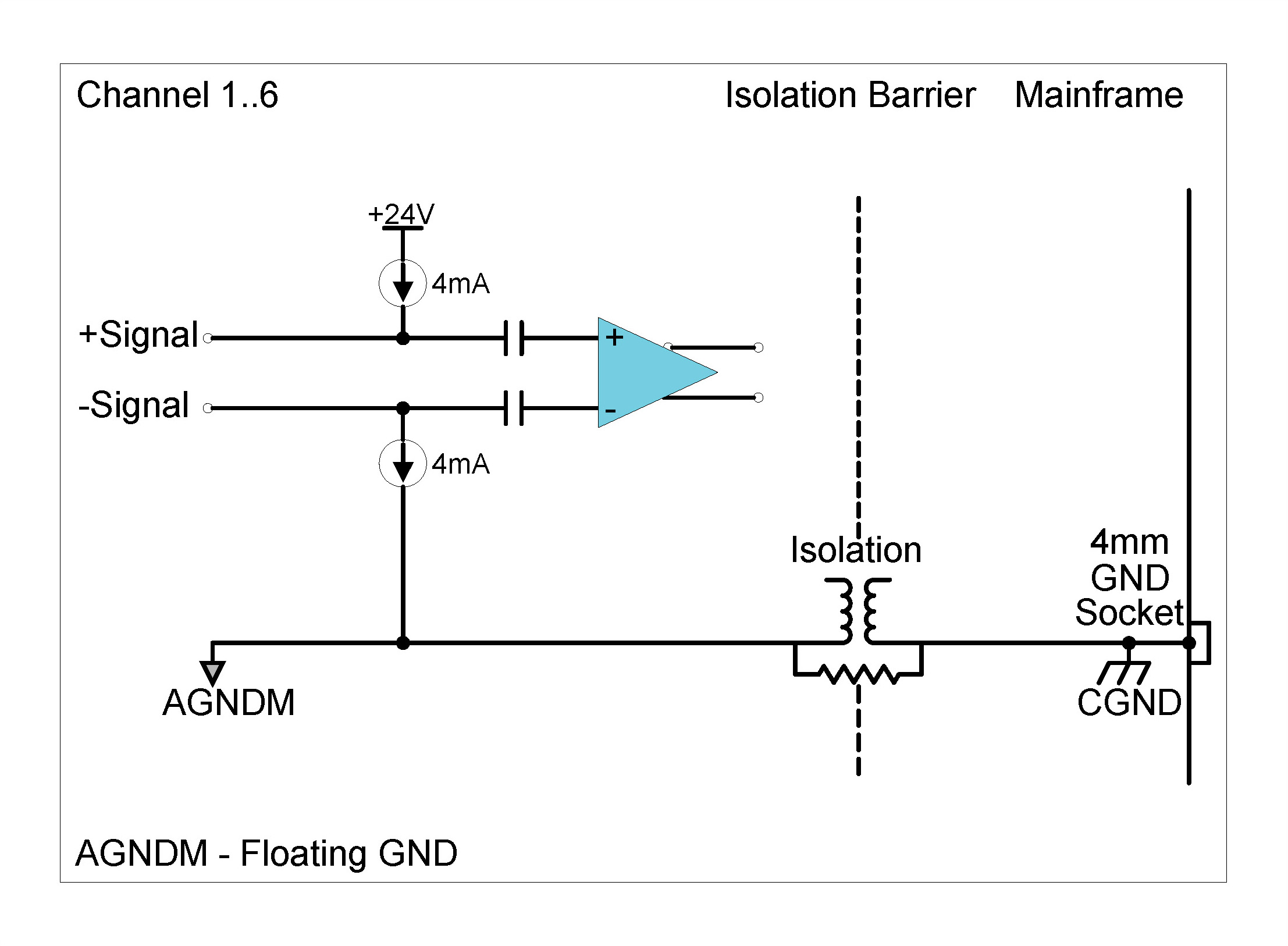

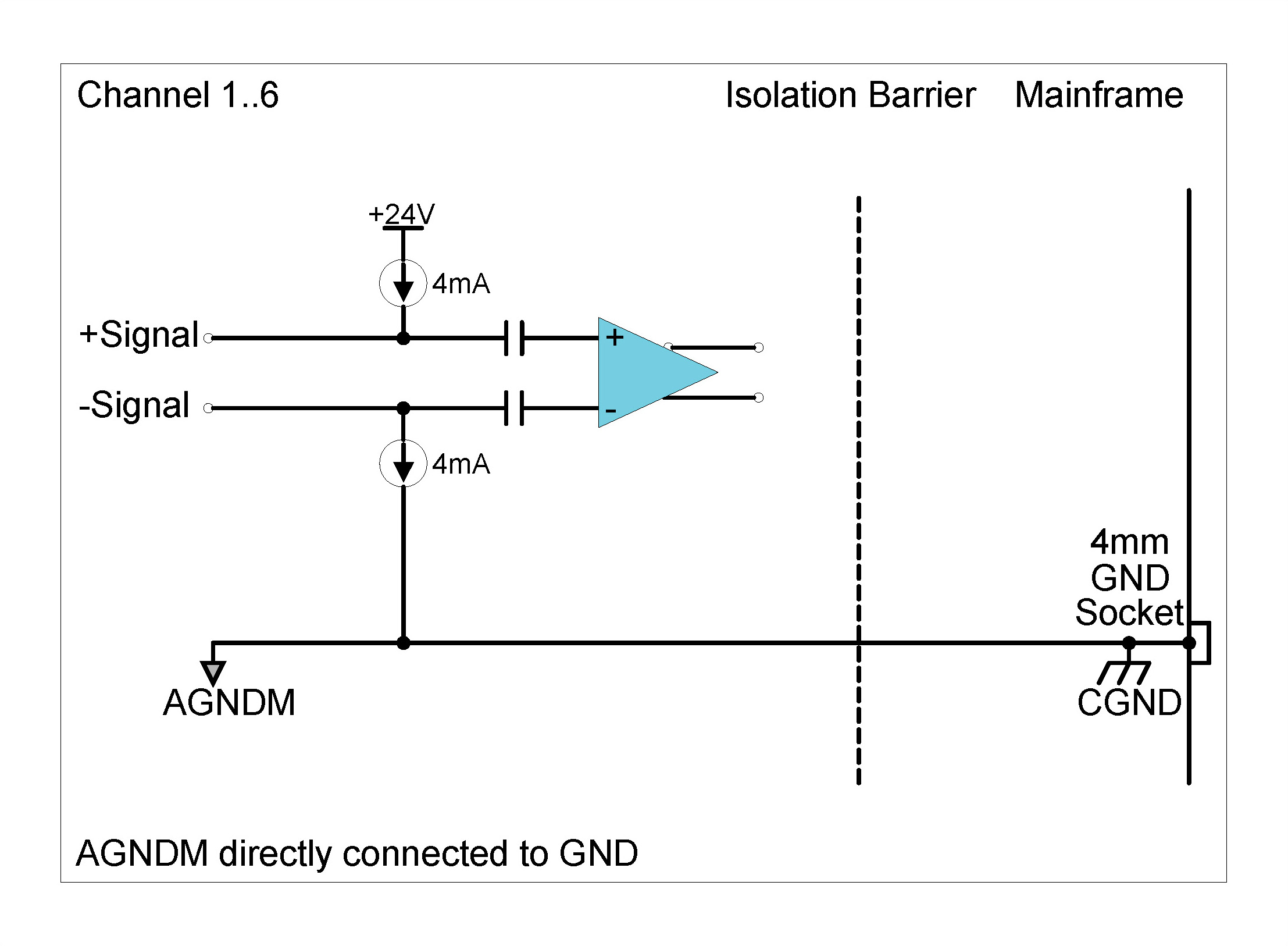

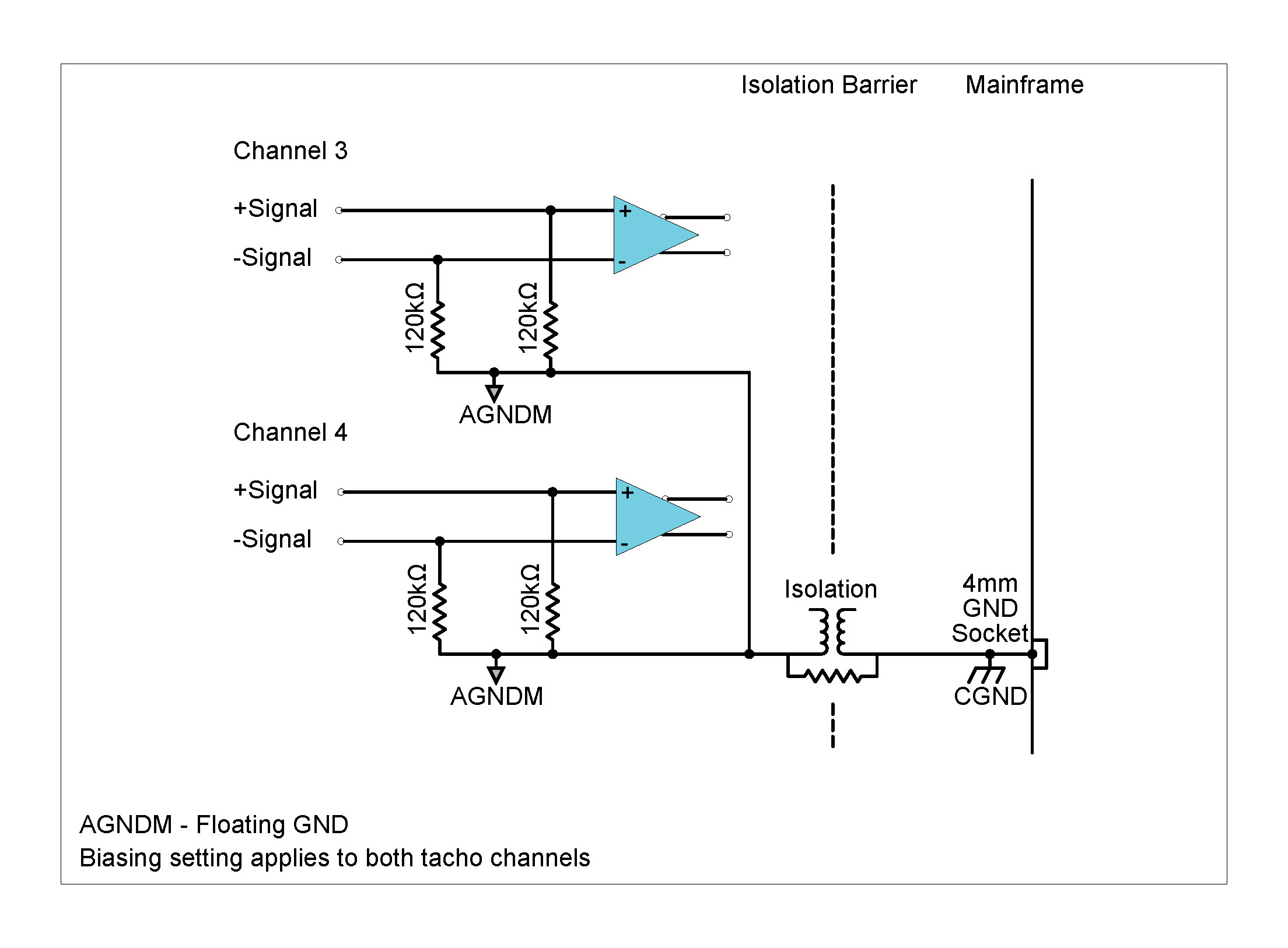

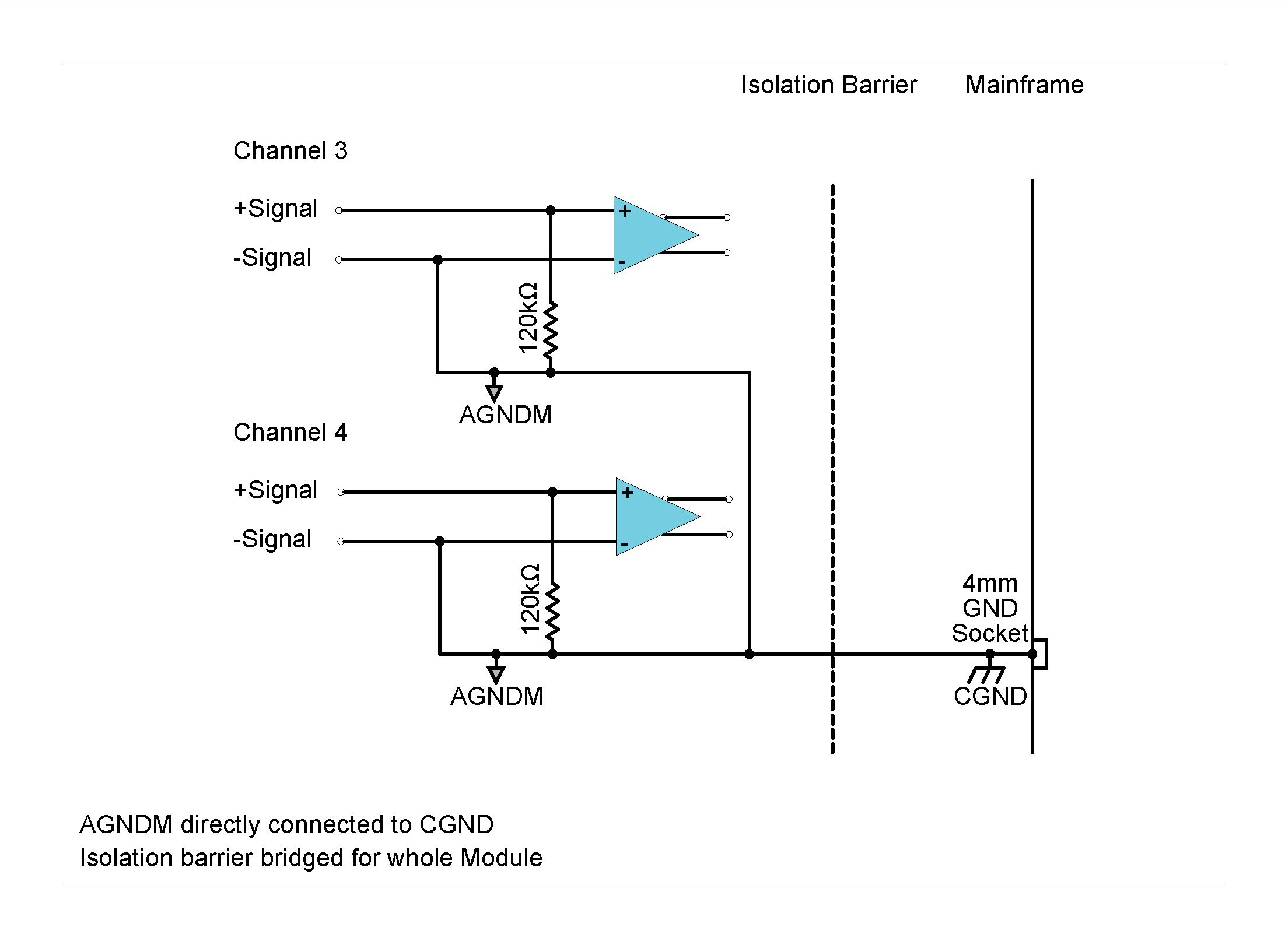

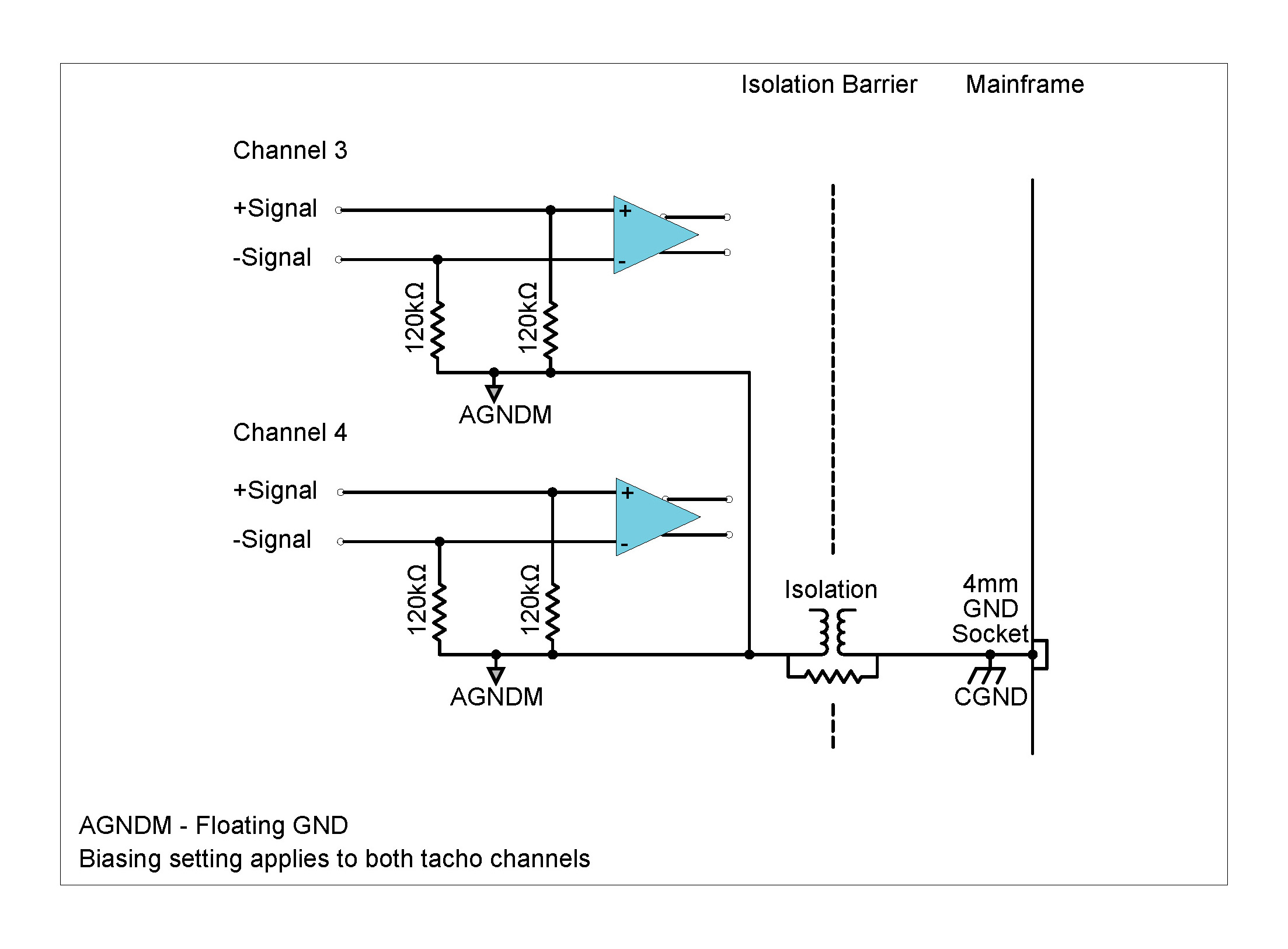

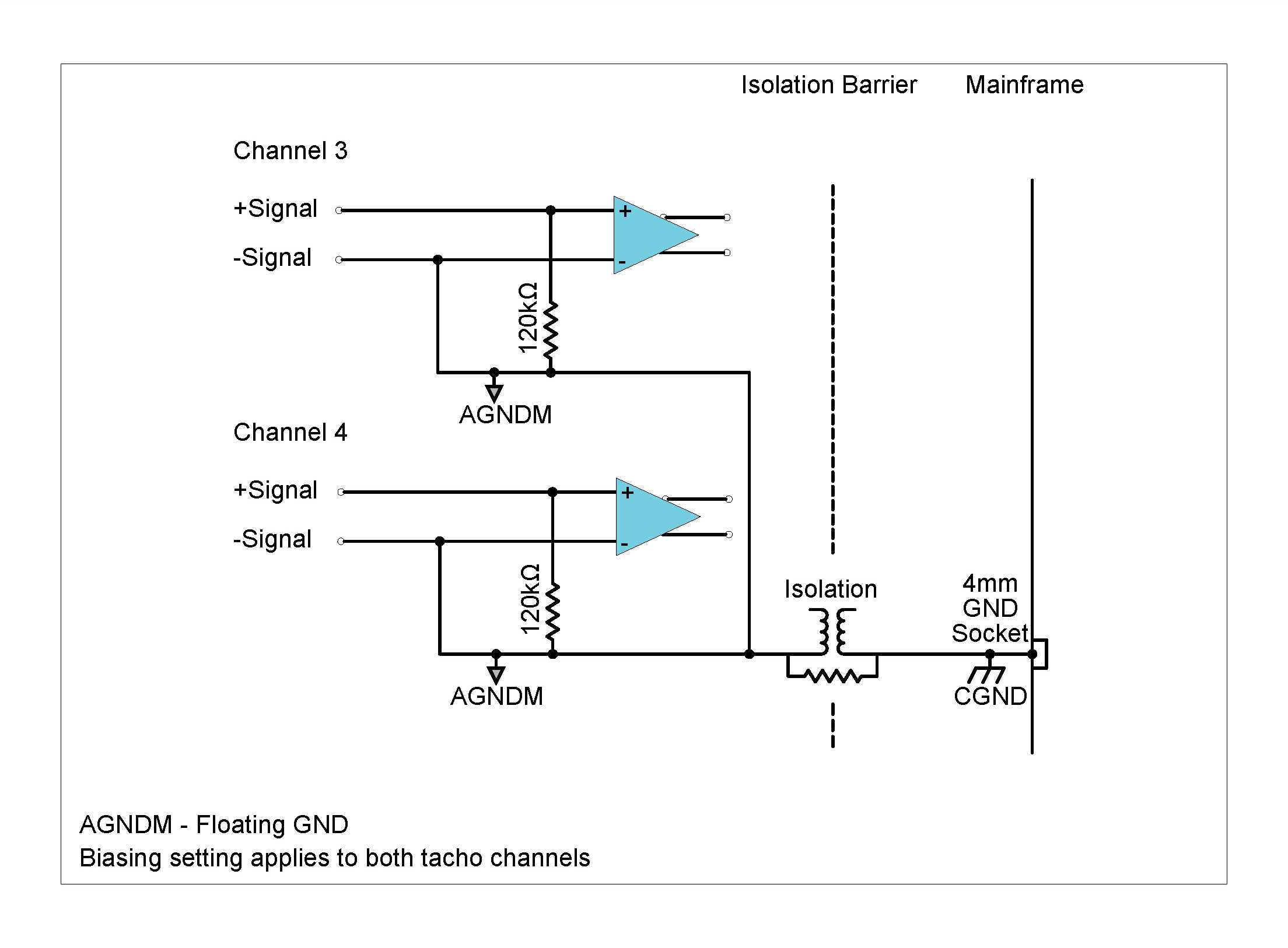

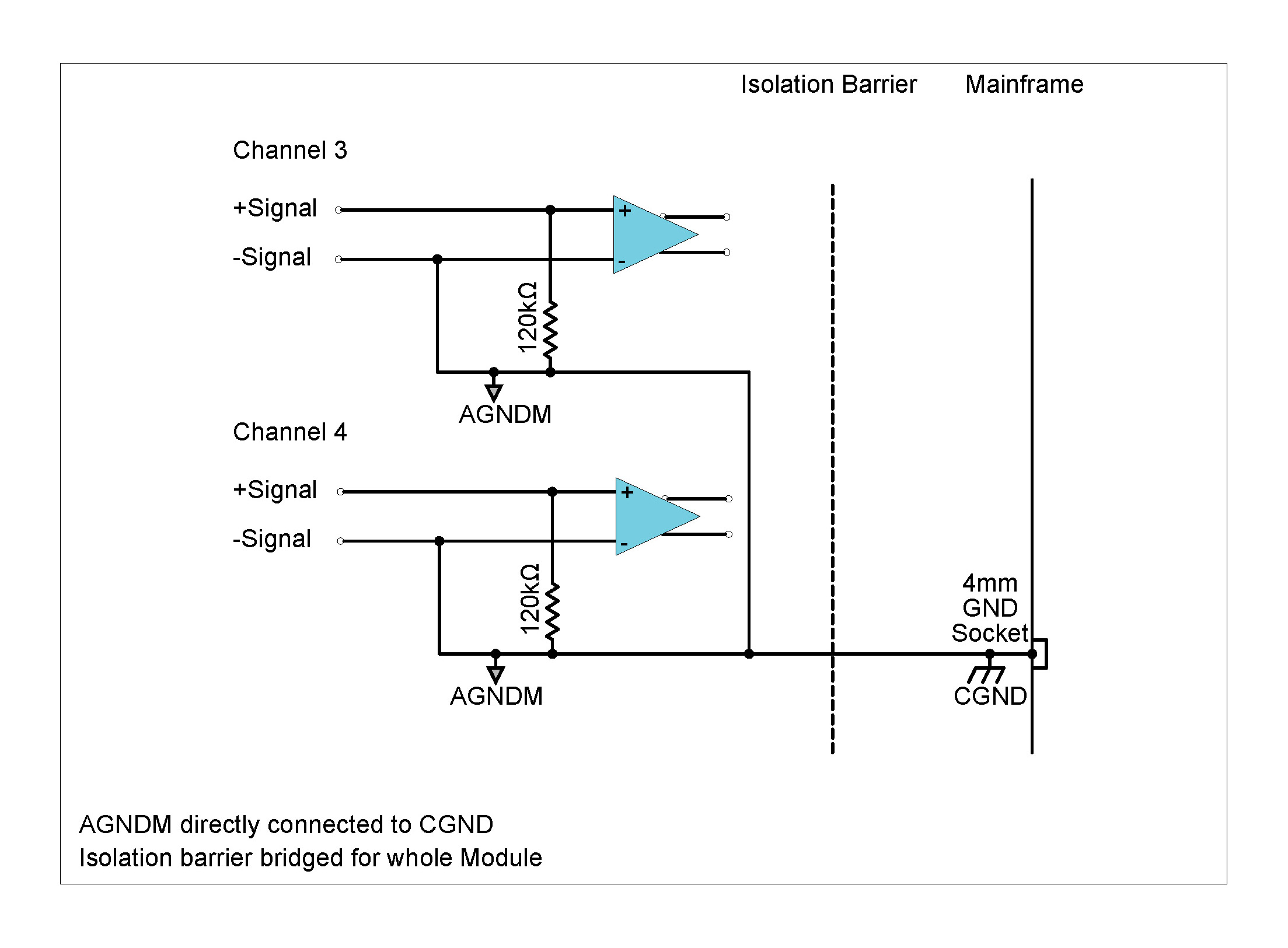

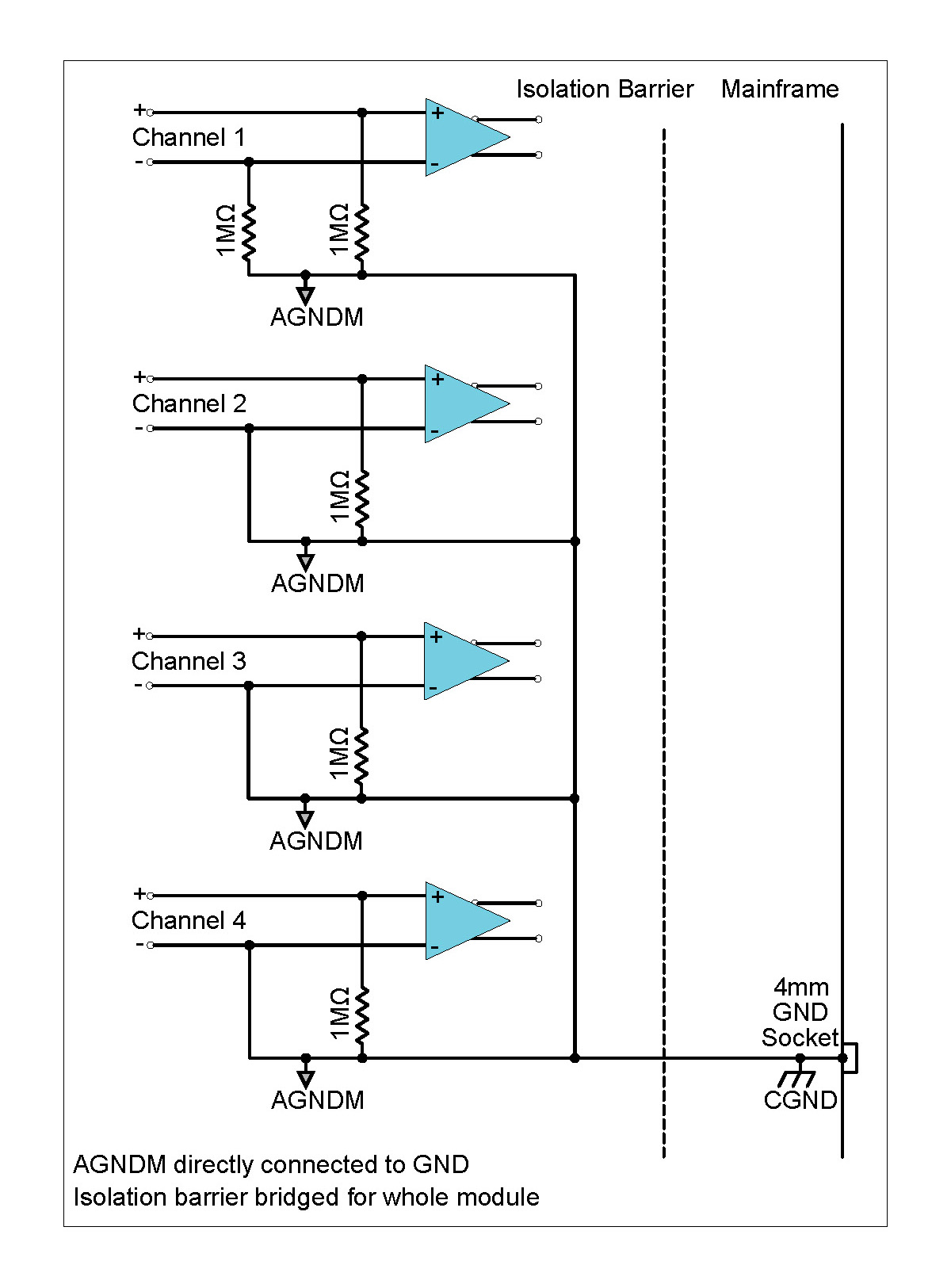

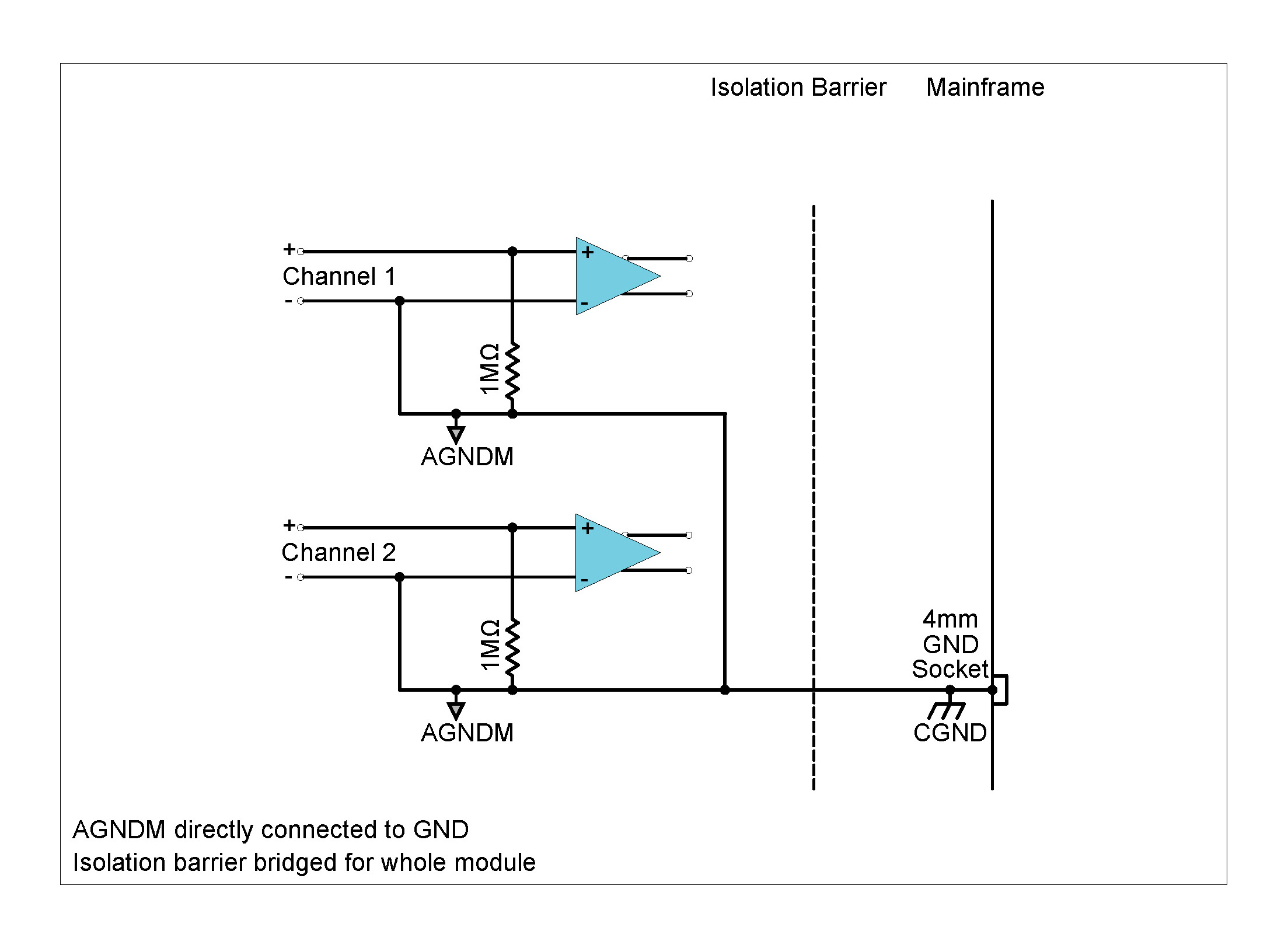

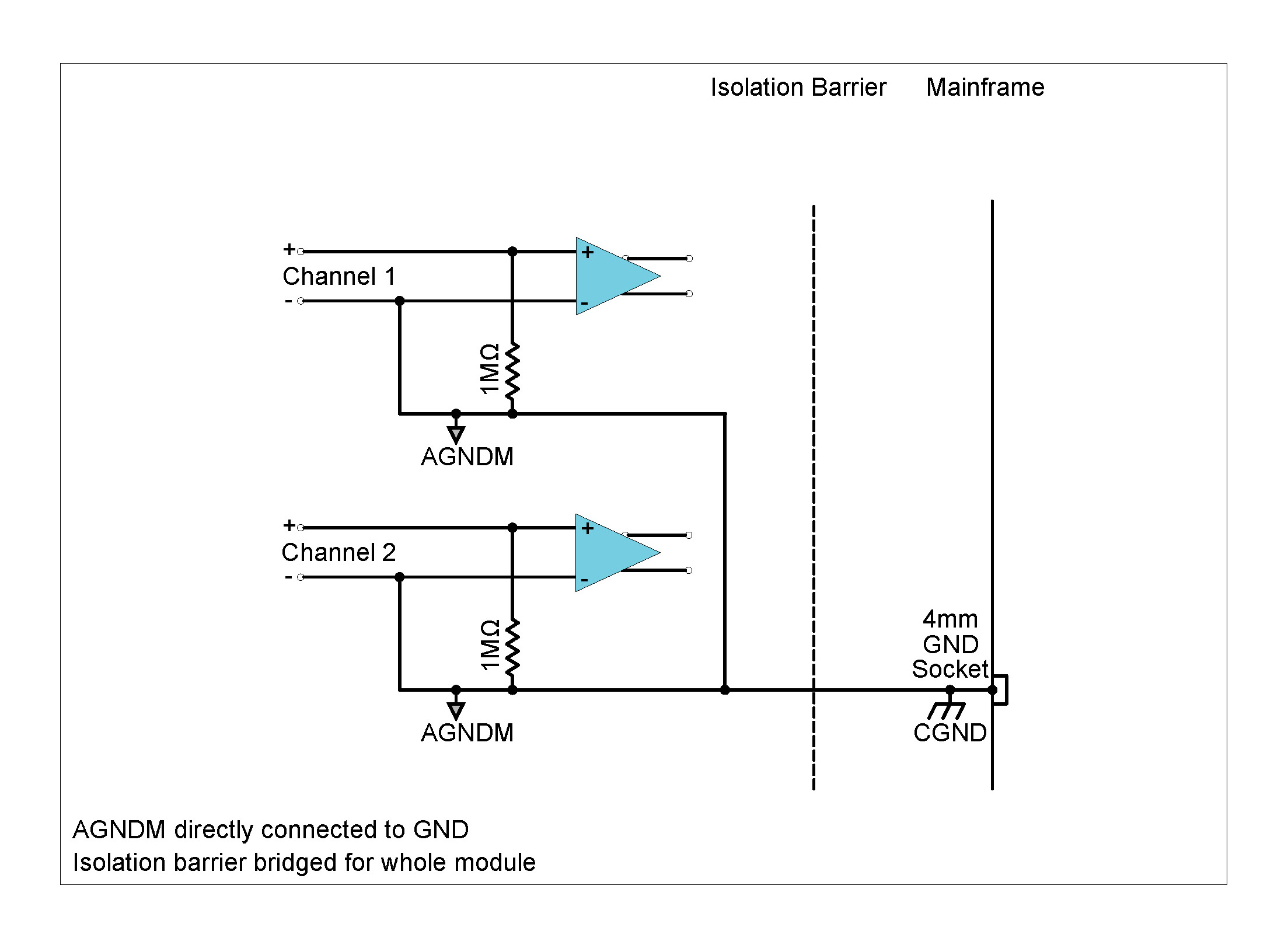

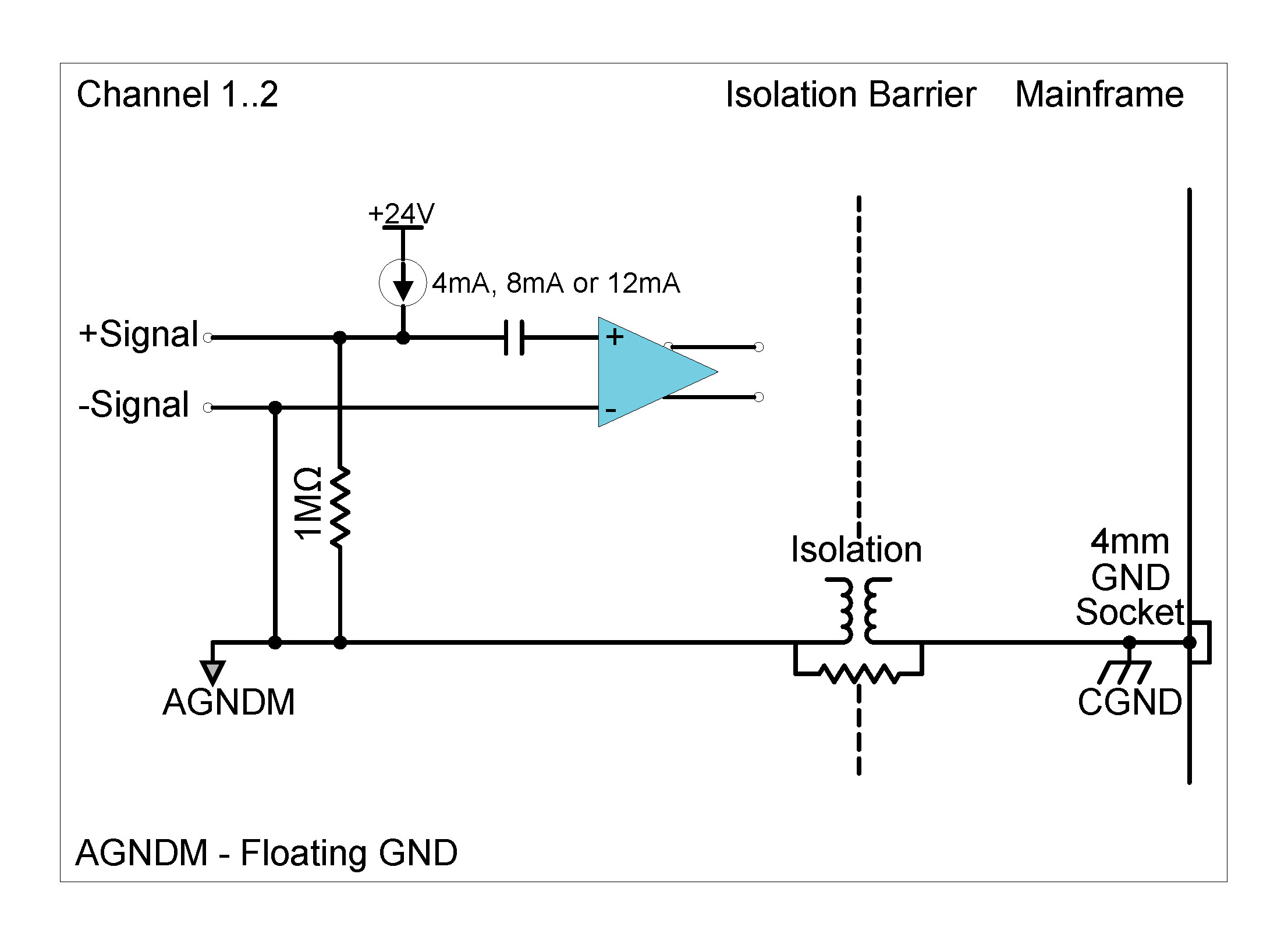

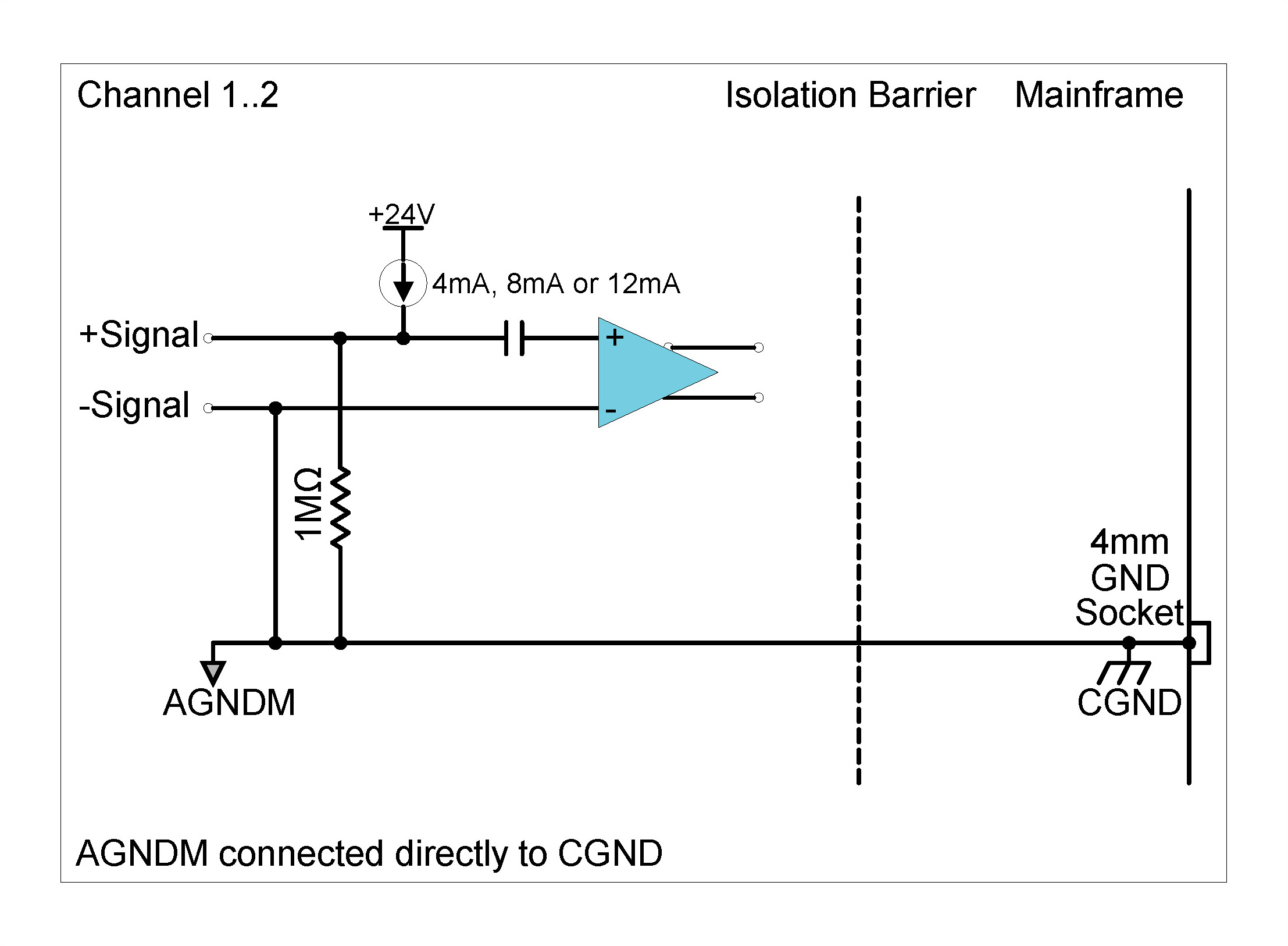

There are four ALI mode grounding options available on the ICS42:

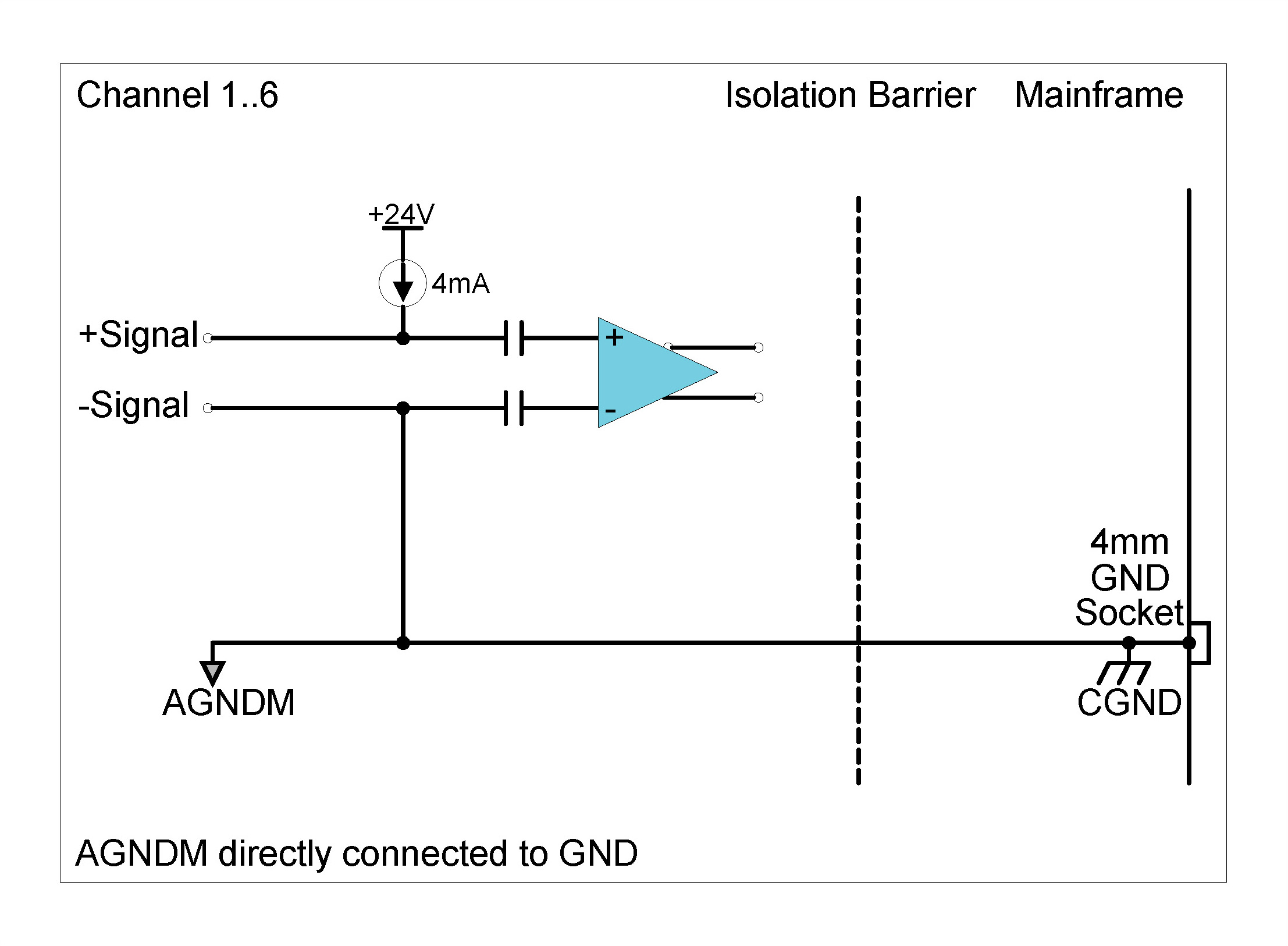

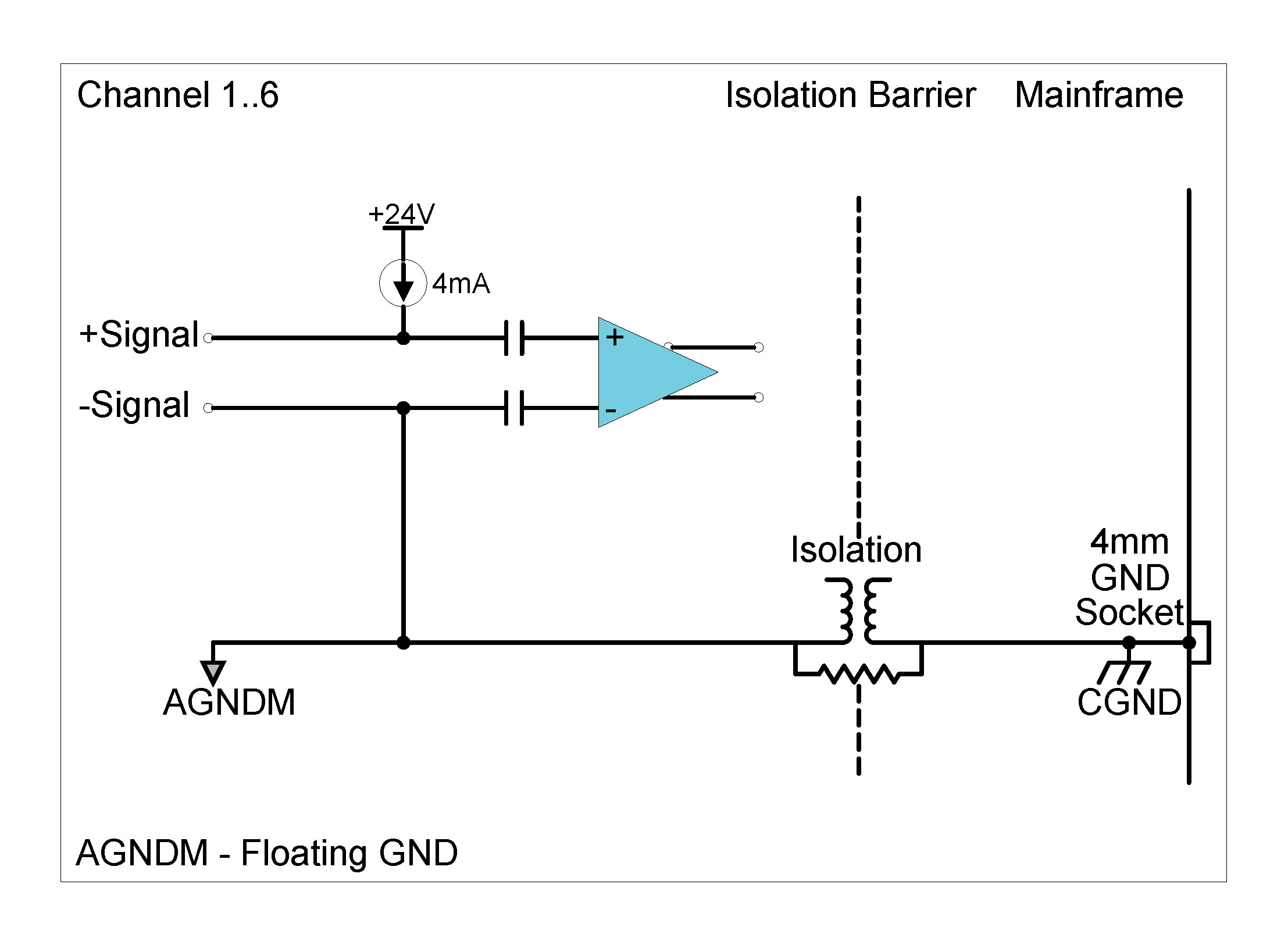

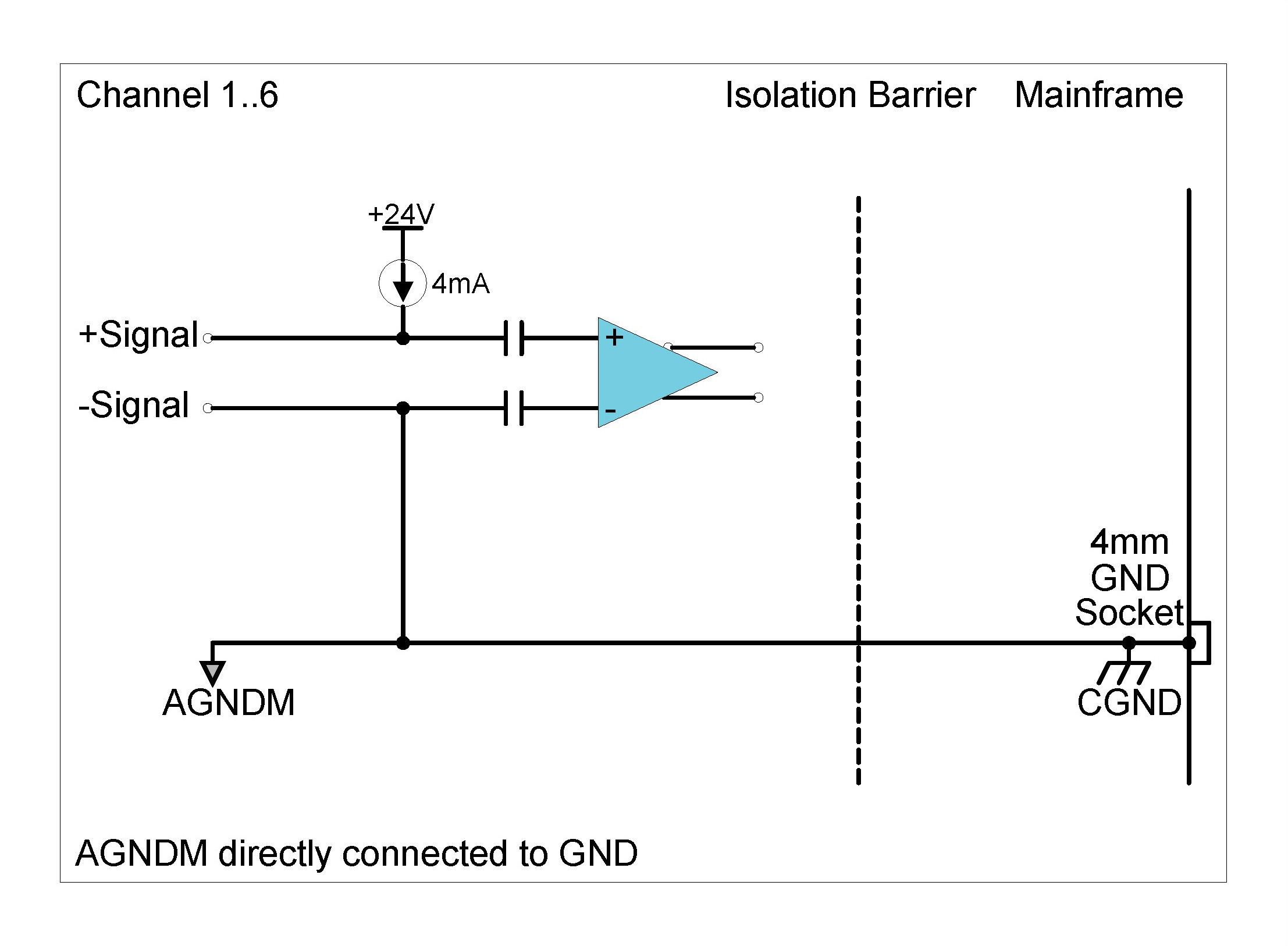

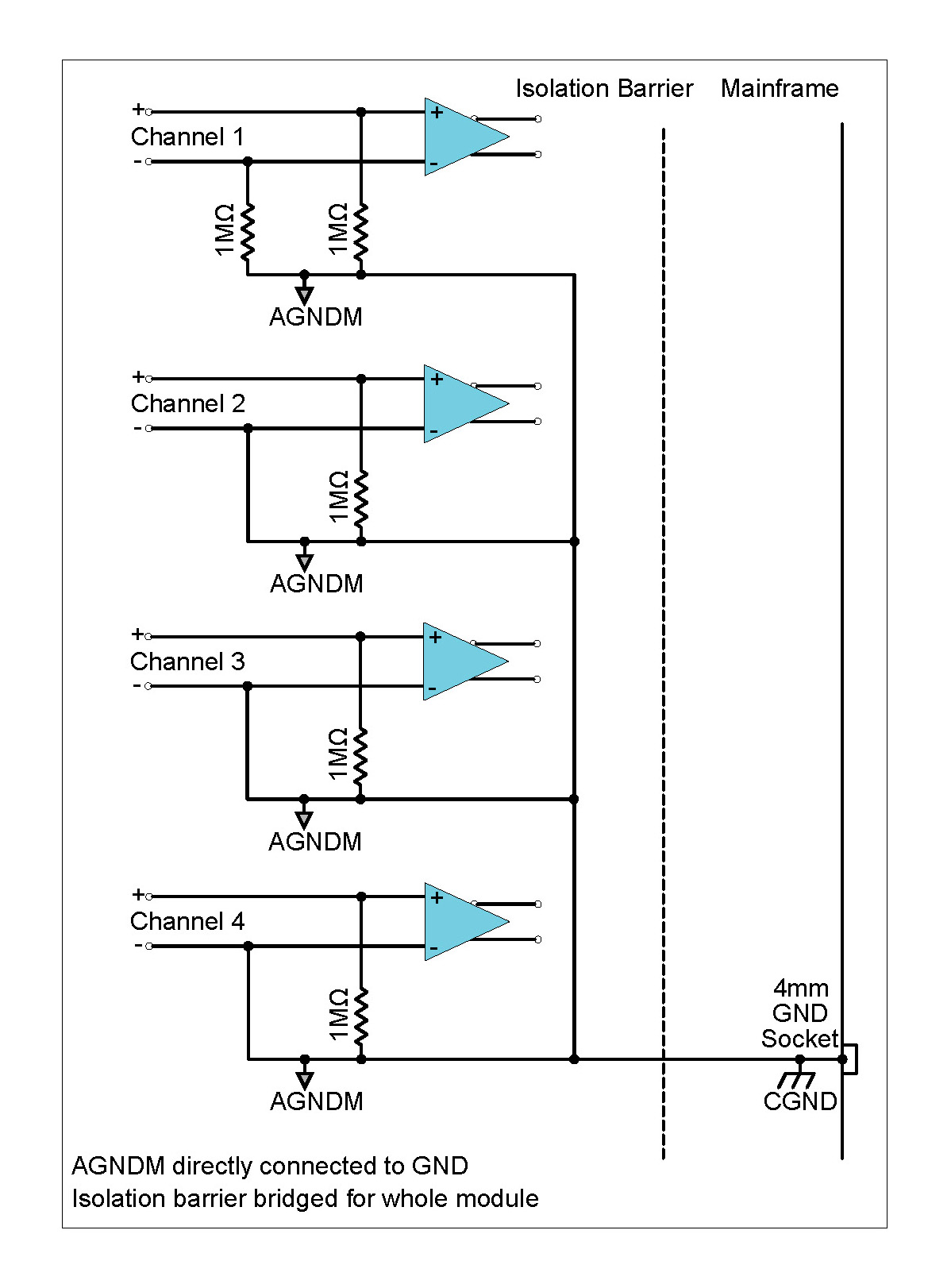

Grounding Diagrams: ALI mode (Voltage Input mode)

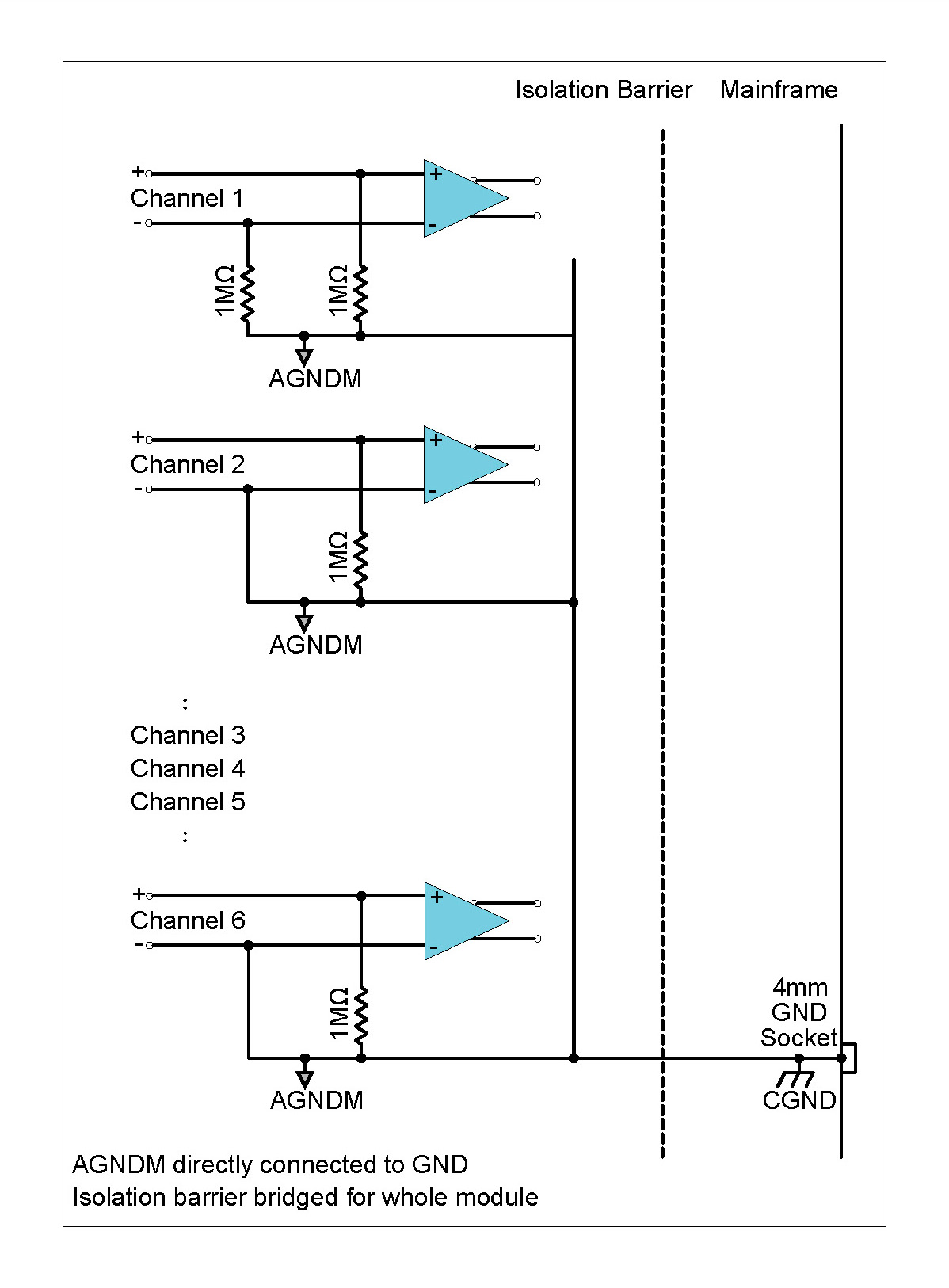

Although each channel in the ICS42 can be set individually as to its grounding type, enabling the ground option on any one channel will cause the isolation barrier of the module to be bridged (i.e. on all six channels AGNDM will be directly connected to CGND).

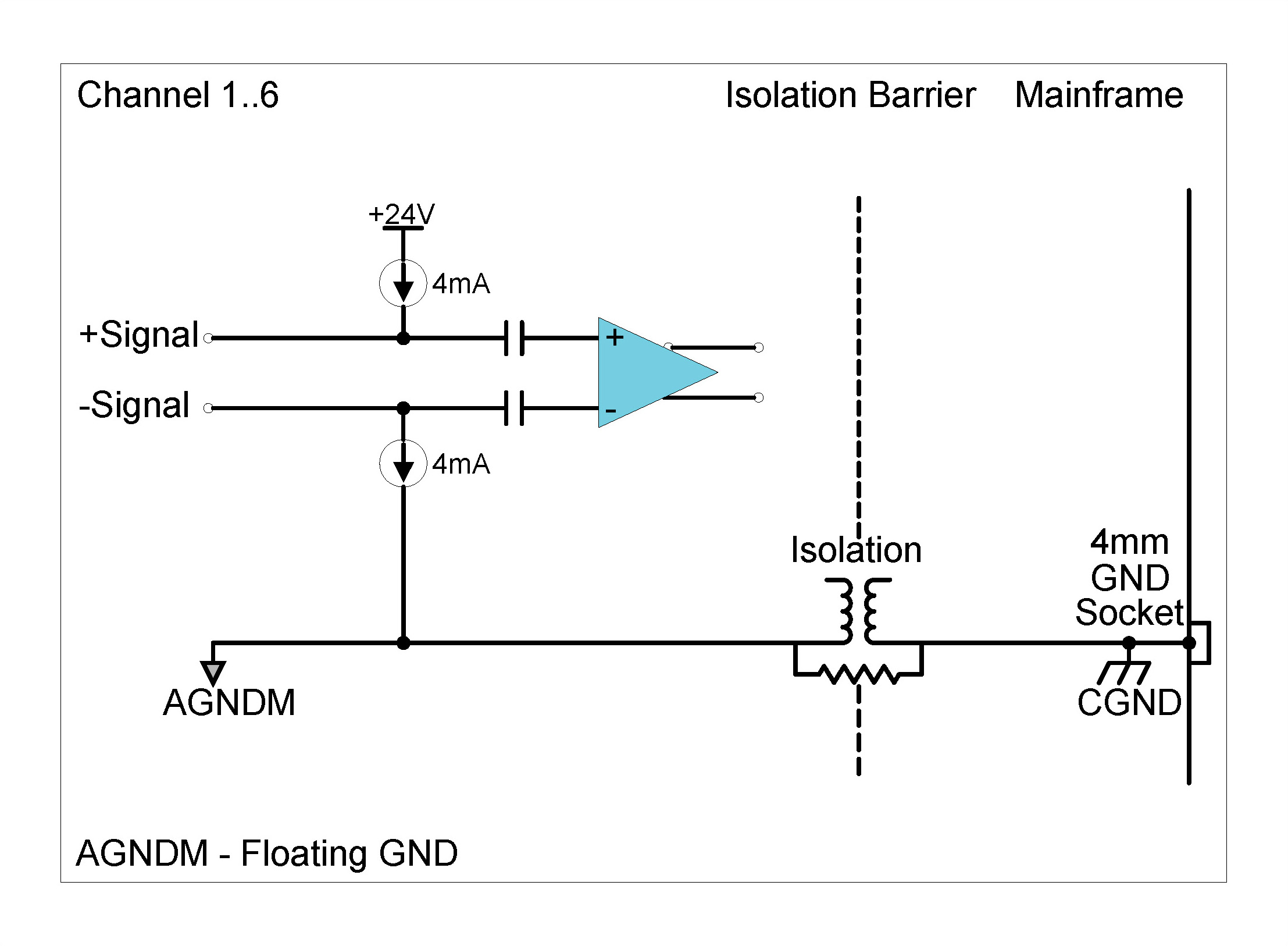

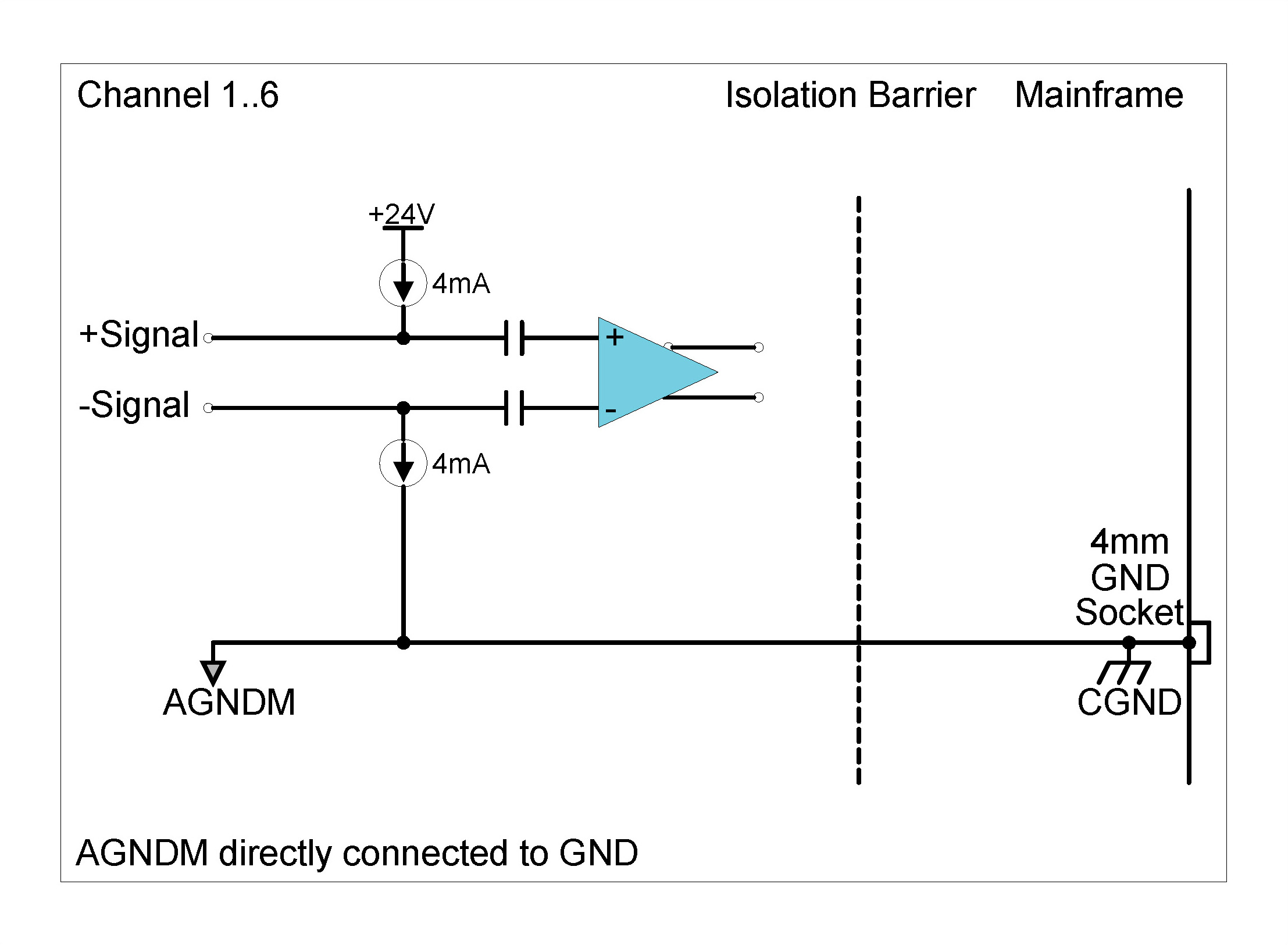

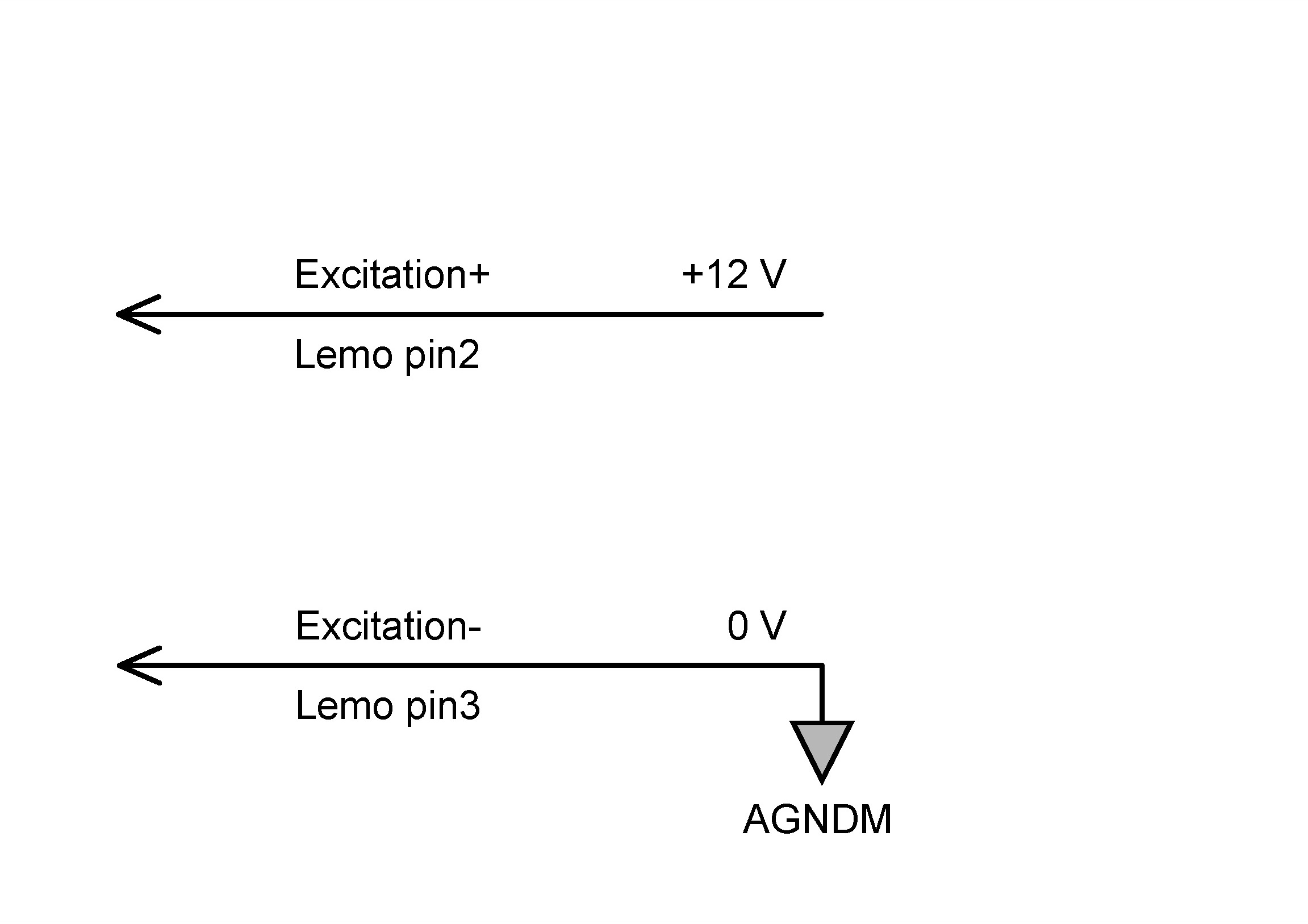

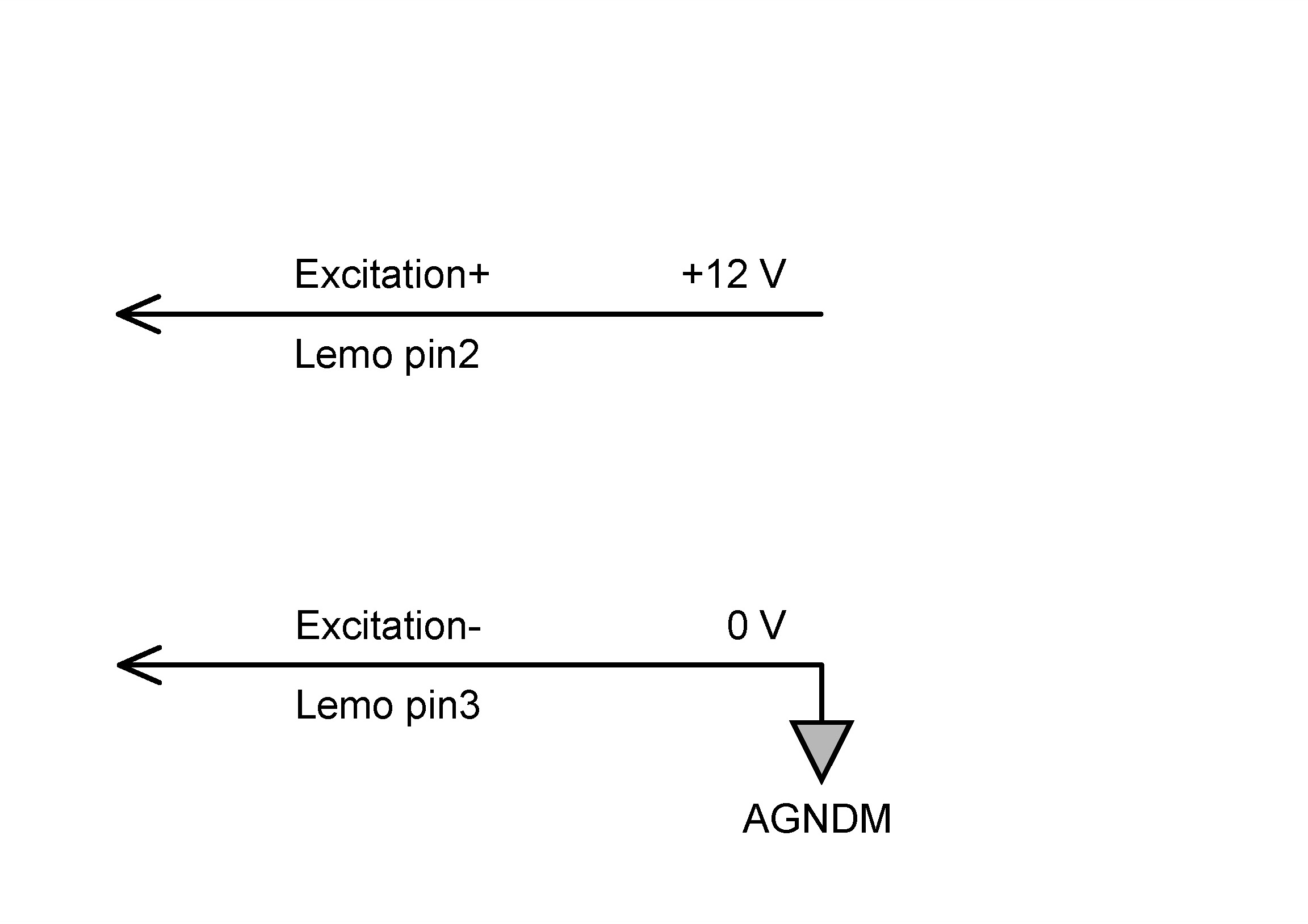

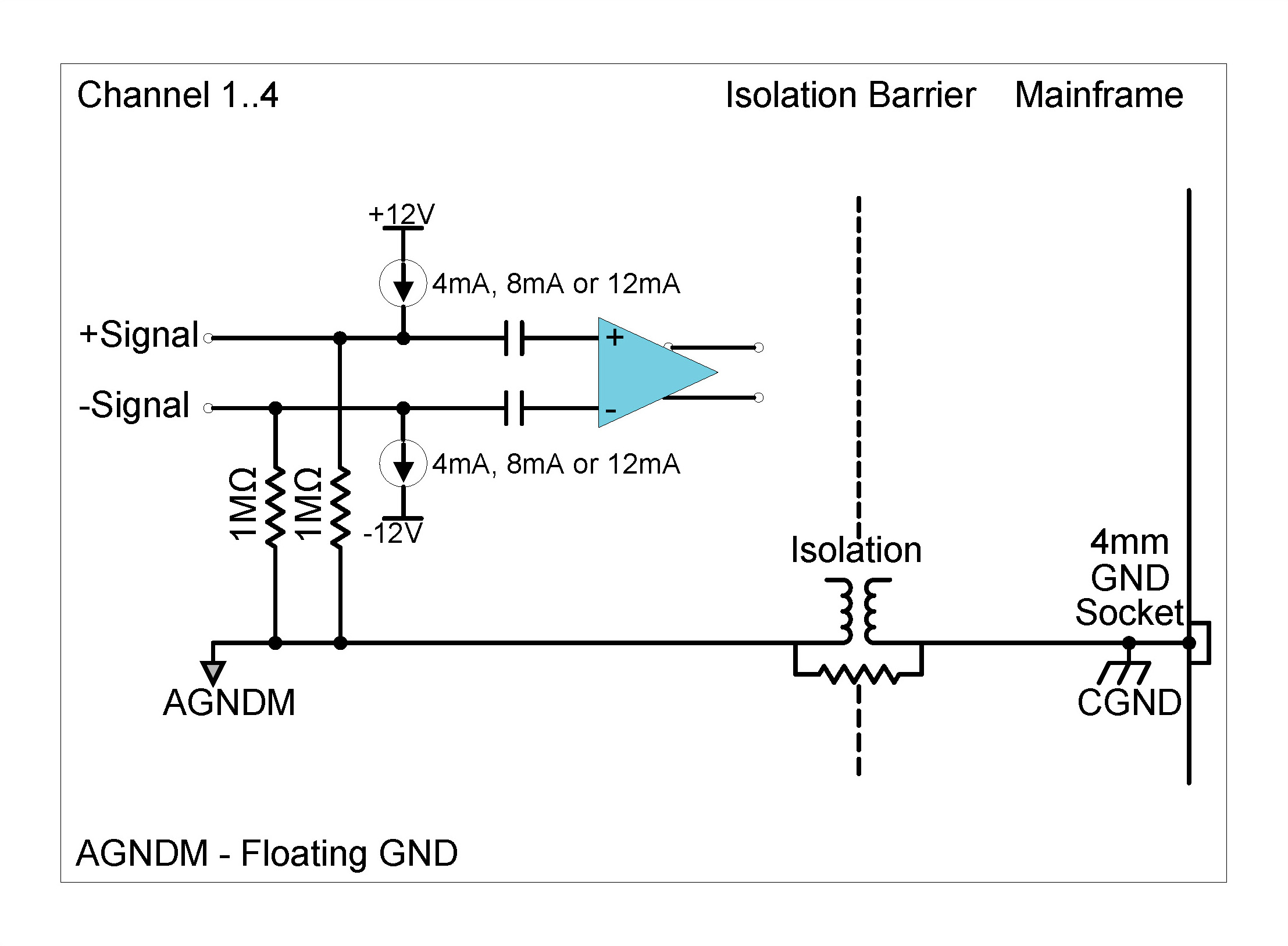

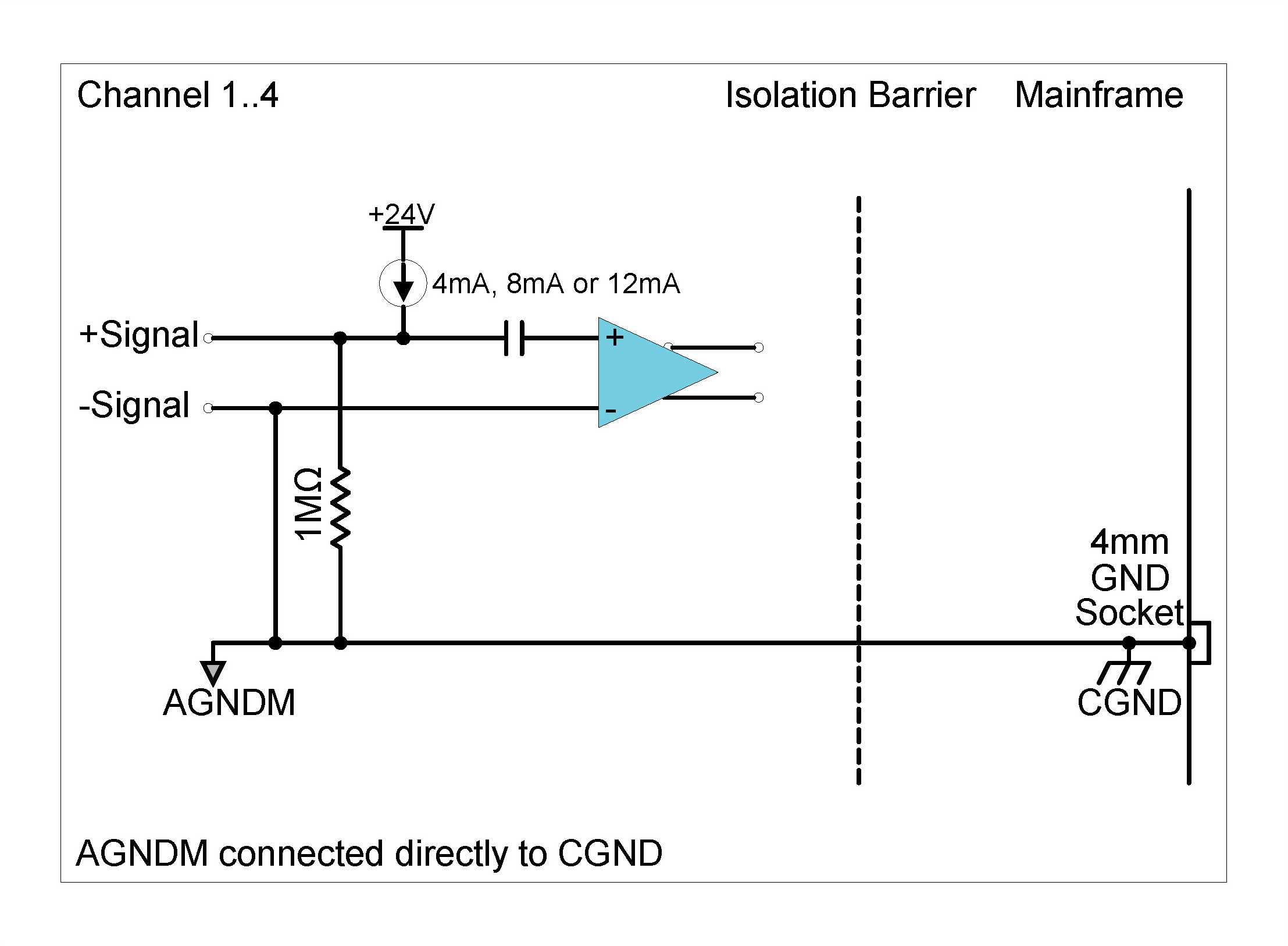

Excitation Diagrams: ICP® Mode

There are two biasing options when using ICP® input mode with 4 mA current excitation, either differential of single-ended. The Biasing settings are independent of the grounding options. The following table shows the different possible settings for the ICS42 Module in ICP® input mode:

| Excitation voltage | Biasing settings | Grounding options |

|---|---|---|

| 24 V (Asymmetrical) | Differential | Ground or Floating ground |

| 24 V (Asymmetrical) | Single-ended | Ground or Floating ground |

ICS42 Module Settings in ICP® input mode with 4 mA current excitation

Description

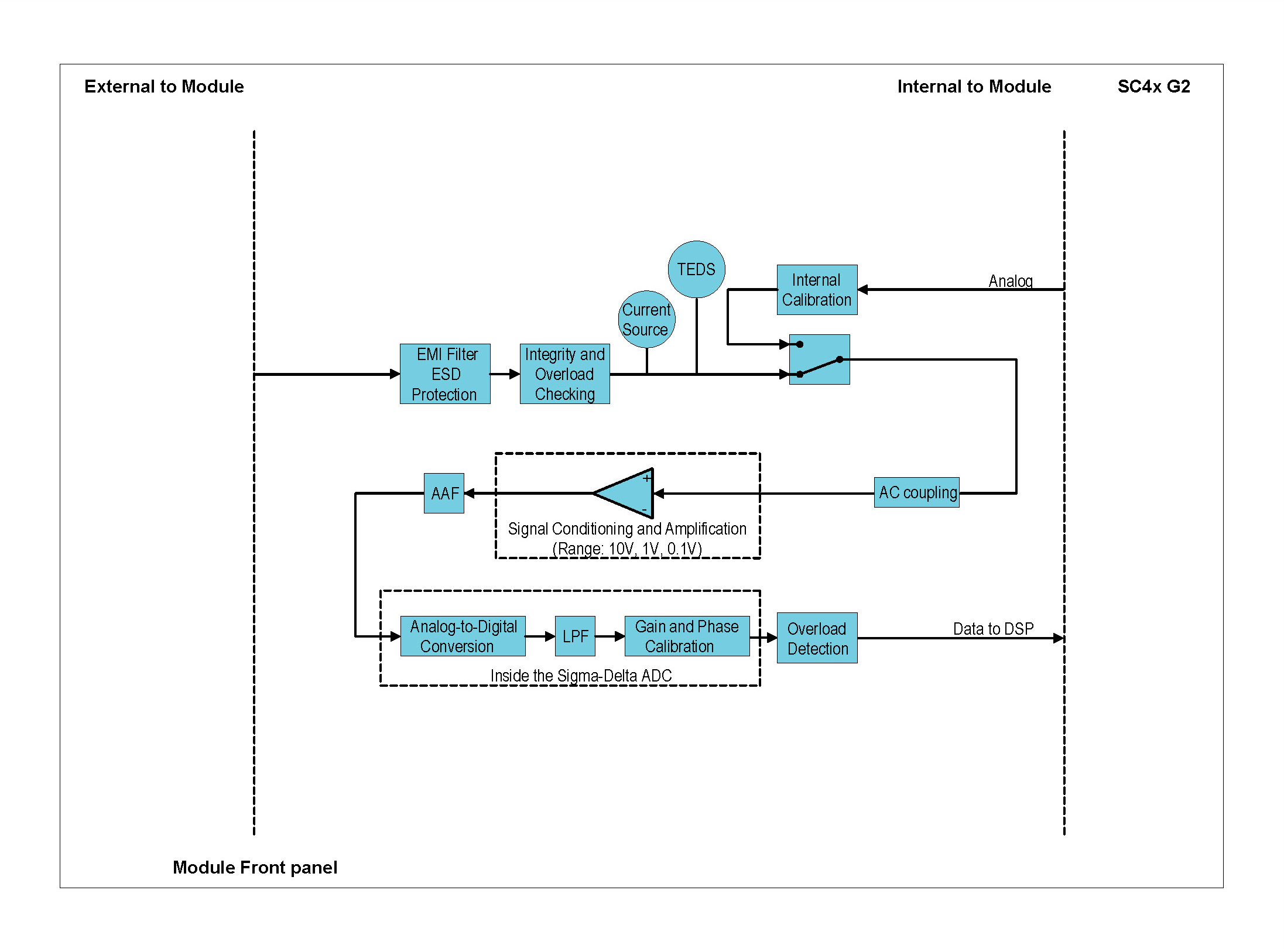

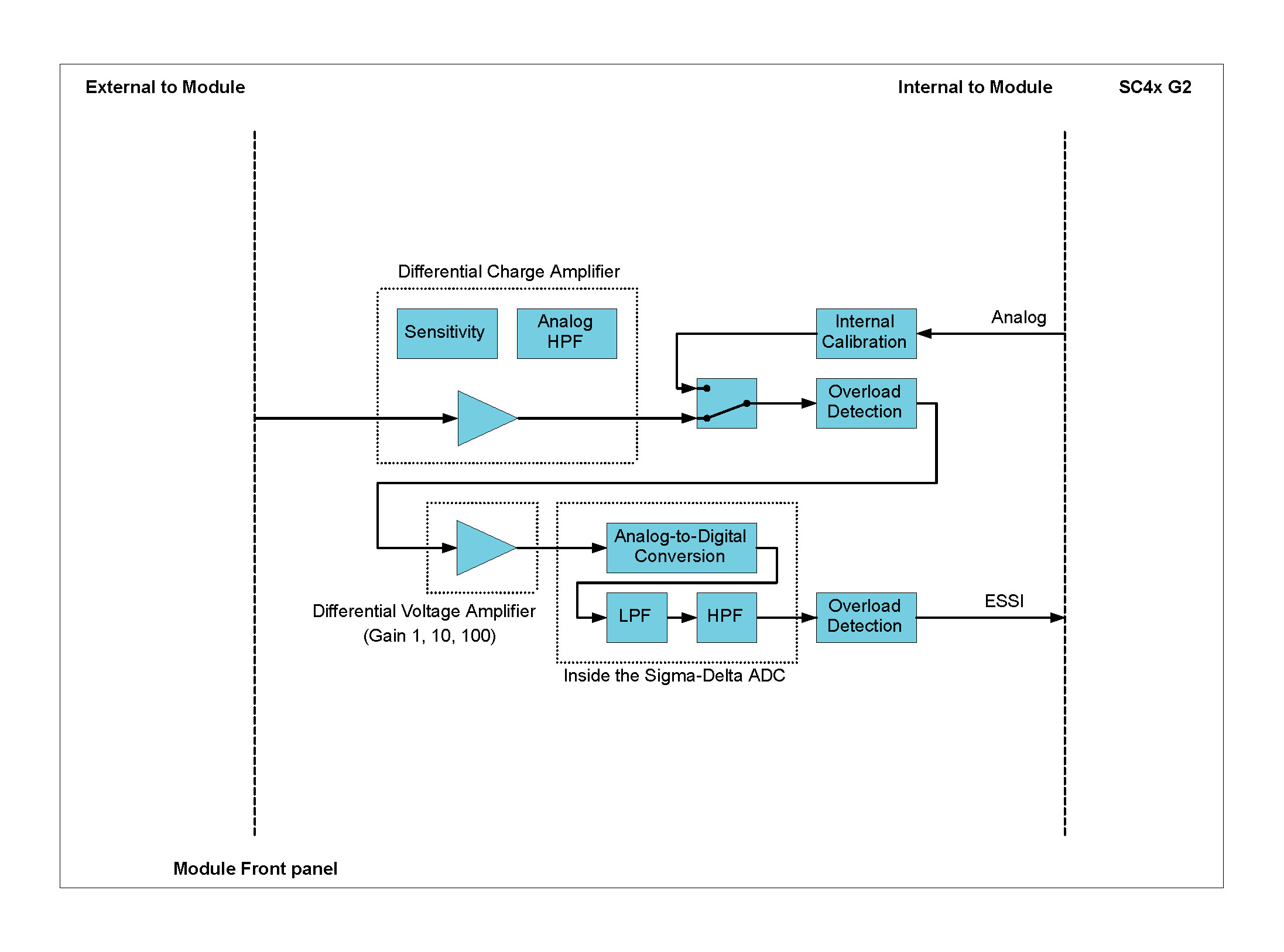

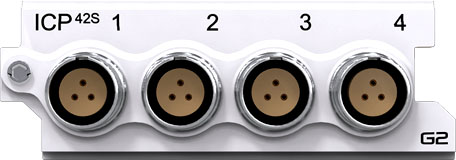

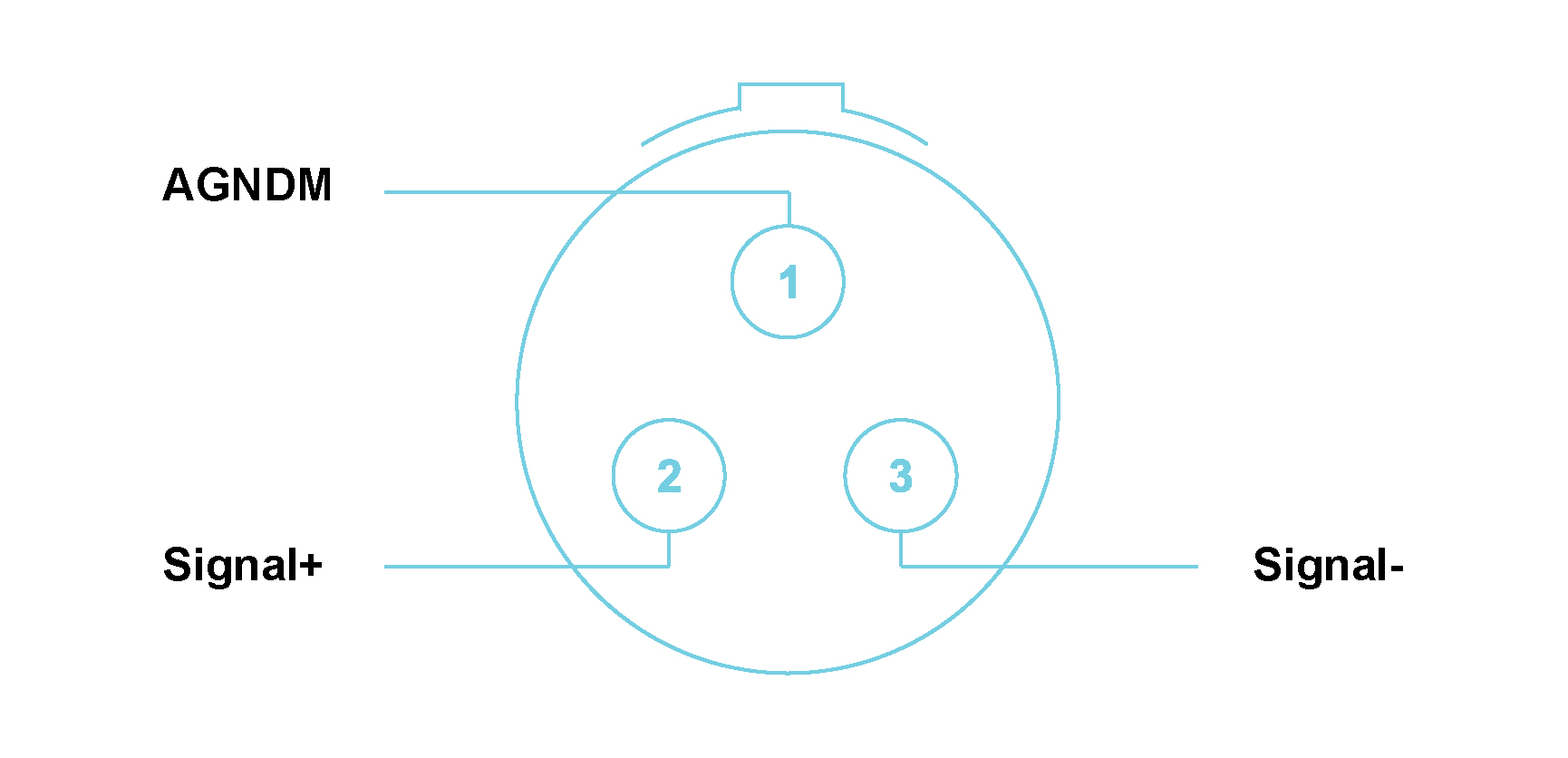

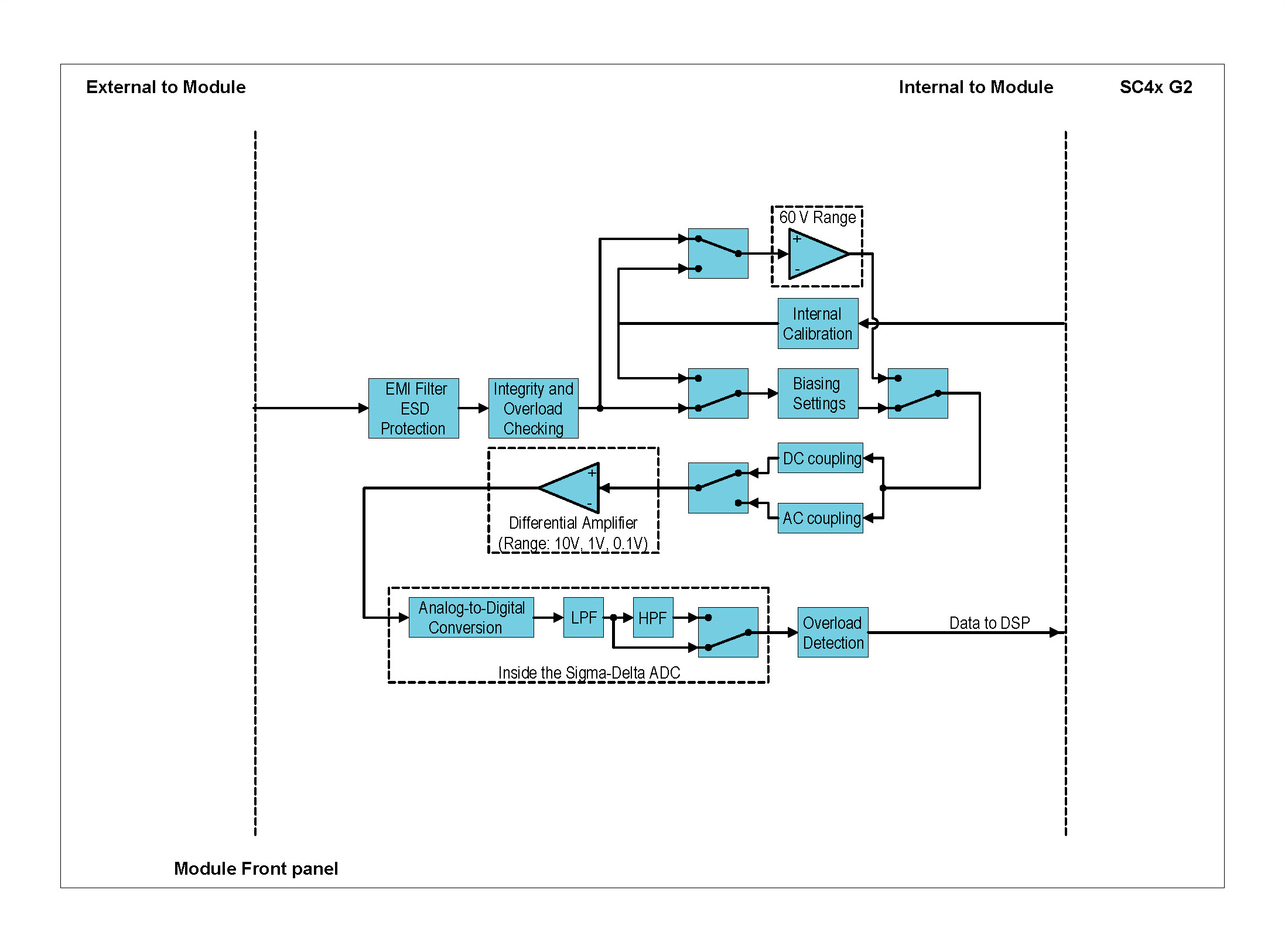

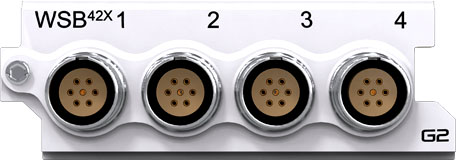

The CHS42X Module can be used with ICP® based accelerometers, force and pressure sensors, quartz or piezoelectric ceramic sensors or to measure analog voltages. The Module can be used:

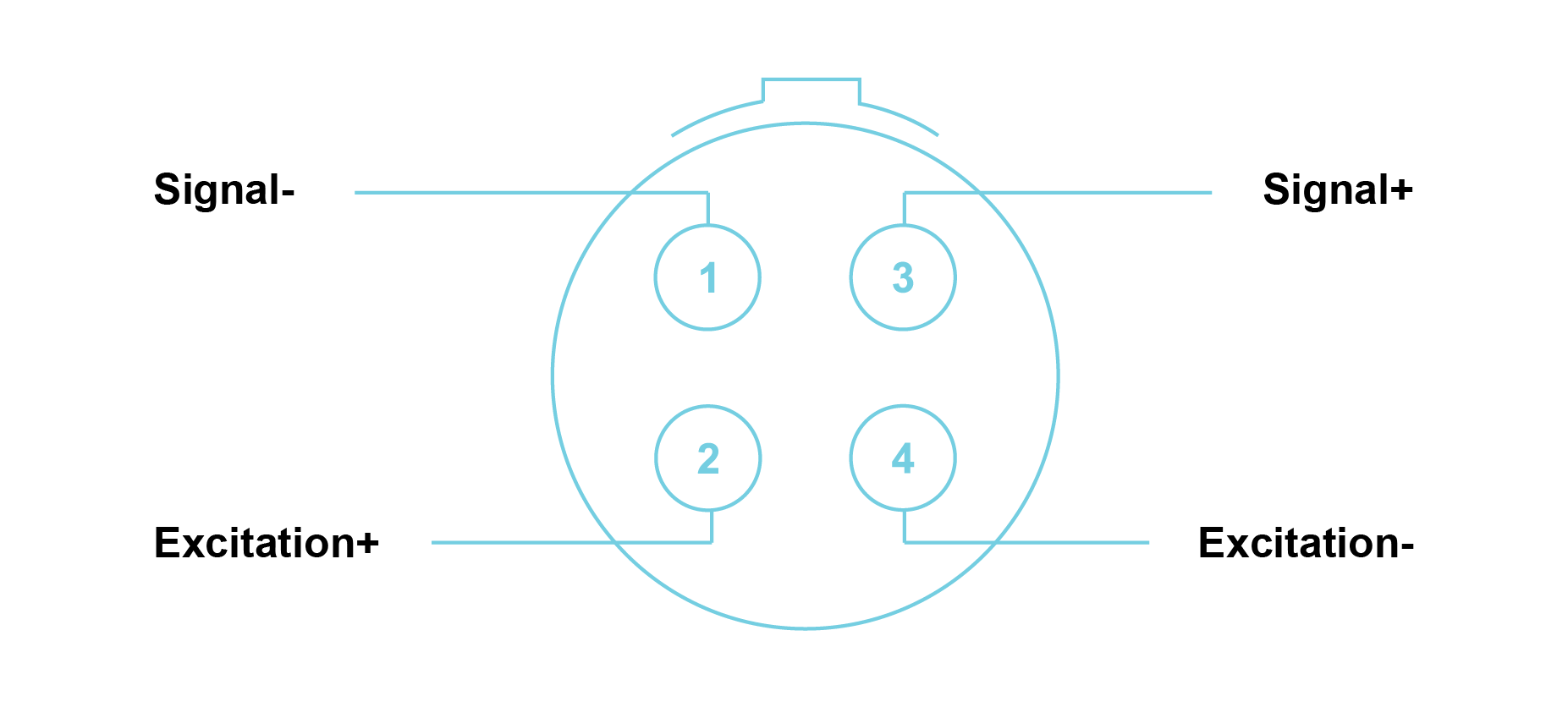

| Front Panel | Connector Information and Pin Definitions |

|---|---|

|

|

CHS42X with LEMO® 9-way EHG.0B connectors Module Pin Definition (when looking into the front panel’s connector or at the rear of the cable’s connector)

ESD WARNING The CHS42X Module inputs are sensitive to ESD damage. Always take care to discharge any additional static electricity that might have built up on a cable and connector before making contact with the CHS42X Module.

ICP® and Voltage Input Mode Features

Please note:The features and specifications may

vary based on the software package utilized with the

DECAQ

CHS42X ICP® and Voltage Input Mode Specifications

| Interface | ICP® | ICP® sensors | |||

| ALI | For analog source voltages | ||||

| Input Coupling | ICP® | AC | |||

| ALI | DC or AC | ||||

| AC Coupling Frequency Response | ICP®/ALI | Attenuation | Min | Max | Unit |

| -3 dB | - | 0.16 | Hz | ||

| Other Sampling Rates | Available through digital LP filters and decimation | ||||

| Optional First Order High-Pass Filter | -3 dB @ 1 Hz | ||||

| Module Calibration | Internal amplitude and phase calibration | ||||

| Protection | ICP®/ALI | 2 kV ESD | |||

| ICP® | Short circuit between sensor case and ground | ||||

| Galvanic Isolation | 50 V | ||||

CHS42X Module ICP® and Voltage Input Mode

Features

| -3 dB Bandwidth | DC to 44.3 kHz | ||

| Maximum Sampling Rate (fs) per Channel | 102.4 kSa/s | ||

| A/D Conversion | 24-bit | ||

| Input Voltage Ranges (Peak) | ±100 mV; ±1 V; ±10 V | ||

| ICP® mode | 4 mA constant current at 24 V excitation | ||

| Input Biasing Settings | Differential Float (Balanced Float) | Both the positive and negative signal inputs are connected through 1 MΩ to floating ground | |

| Single-Ended Float (Unbalanced Float) | Positive signal input connected through 1 MΩ to floating ground; Negative signal input connected to floating ground | ||

| Single-Ended GND (Unbalanced GND) | Positive signal input connected through 1 MΩ to ground; Negative signal input connected to ground | ||

| Input Impedance | Differential | 2 MΩ ‖ 80 pF | |

| Single Ended | 1 MΩ ‖ 100 pF | ||

|

Digital Low-Pass Filter Filter scales with sampling rate |

Passband | fs x 0.433 Hz | |

| Stopband | fs x 0.499 Hz | ||

| Passband Ripple | ±0.005 dB | ||

| Stopband Attenuation | 105 dB | ||

|

Phase Accuracy for Voltage Input / ICP® Mode All channels in Voltage Input / ICP® mode |

Typical1 | ±0.2° at 10 kHz | |

|

Phase Accuracy for Charge and Voltage Input / ICP®

mode Channels in combination of Charge and Voltage Input / ICP® mode |

Typical2,3 | ±0.7° at 10 kHz | |

CHS42X Module ICP® and Voltage Input Mode

Specifications 1Measured in 10 V range at 102.4

kSa/s with all channels in voltage input / ICP® mode.

2Measured in 10 V range at 102.4 kSa/s with 3 channels in

charge mode and 3 channels in voltage input mode.

3Valid

for charge mode sensitivities 1 mV/pC and 0.1 mV/pC.

| DC Voltage Accuracy | Input Range (Peak) | Reading + % Range | ||

| ±100 mV | 0.200 % + 0.200 % | |||

| ±1 V | 0.068 % + 0.020 % | |||

| ±10 V | 0.113 % + 0.015 % | |||

|

Noise Input terminated by 50 Ω resistor |

Input Range (Peak) | Guaranteed | Typical | |

| 10 Hz to 22 kHz | ±100 mV | < 2.6 µVrms | < 2.2 µVrms | |

| 10 Hz to 44.3 kHz | < 4 µVrms | < 3 µVrms | ||

| 10 Hz to 22 kHz | ±1 V | < 9 µVrms | < 6 µVrms | |

| 10 Hz to 44.3 kHz | < 14 µVrms | < 10 µVrms | ||

| 10 Hz to 22 kHz | ±10 V | < 45 µVrms | < 40 µVrms | |

| 10 Hz to 44.3 kHz | < 113 µVrms | < 84 µVrms | ||

| Dynamic Range4 Input terminated by 50 Ω resistor | Input Range (Peak) | Typical | ||

| ±100 mV | > 120 dB | |||

| ±1 V | > 130 dB | |||

| ±10 V | > 130 dB | |||

|

Amplitude Flatness Relative to 1 kHz Measured up to 0.39 x fs |

Sampling Rate (fs) | Input Range (Peak) | Attenuation (Input signal level 100 % of full range) | |

| 51.2 kSa/s | ±100 mV | − 0.06 dB | ||

| 102.4 kSa/s | − 0.10 dB | |||

| 51.2 kSa/s | ±1 V | − 0.04 dB | ||

| 102.4 kSa/s | − 0.05 dB | |||

| 51.2 kSa/s | ±10 V | − 0.03 dB | ||

| 102.4 kSa/s | − 0.04 dB | |||

| Crosstalk | Input Range (Peak) | Guaranteed | Typical | |

| ±100 mV | 113 dB | 118 dB | ||

| ±1 V | 110 dB | 115 dB | ||

| ±10 V | 102 dB | 107 dB | ||

CHS42X Module ICP® and Voltage Input Mode Specifications

4 Dynamic range calculated at sampling rate of 51.2 kSa/s,

with a 4096-point FFT.

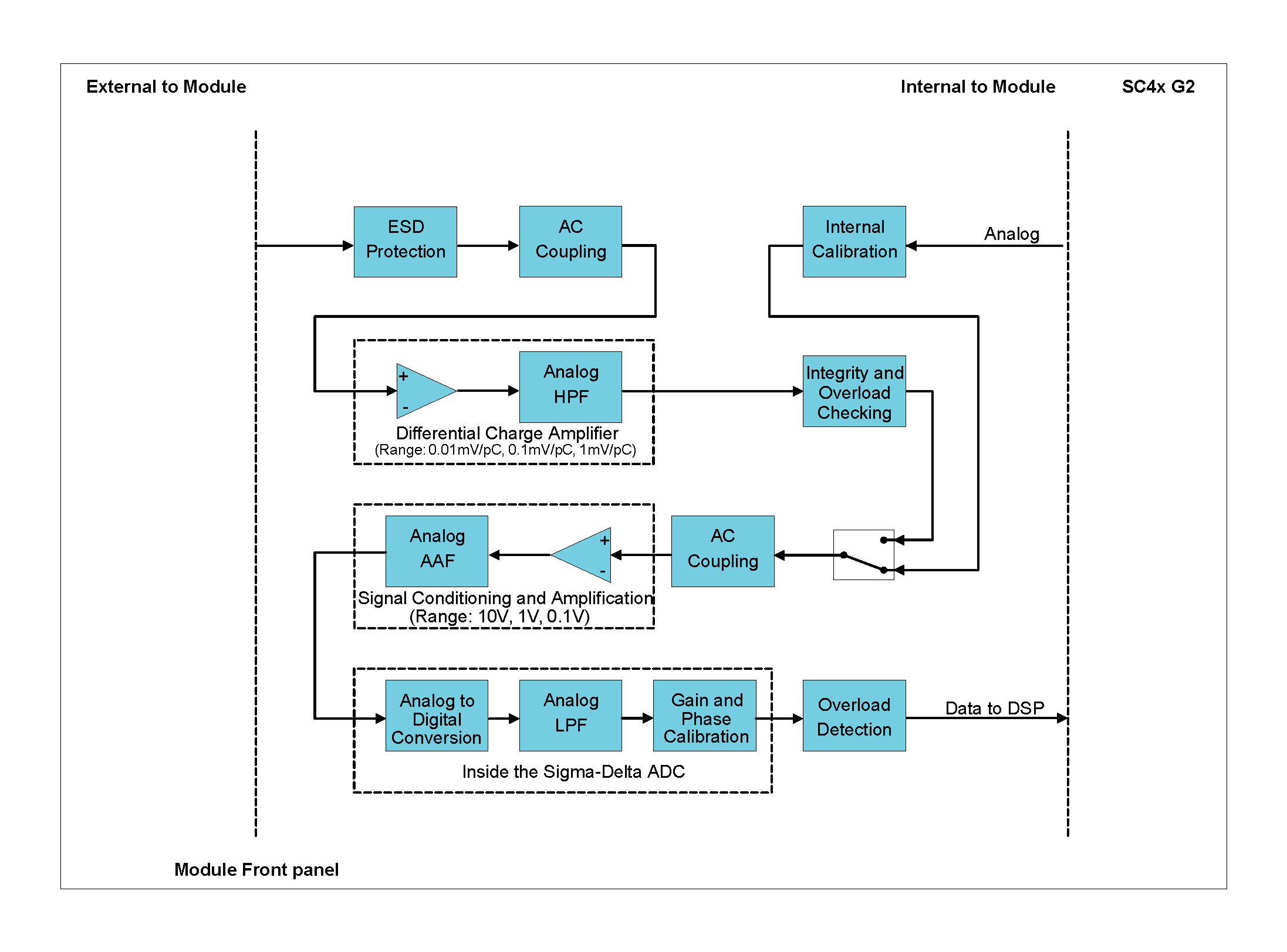

Charge Input Mode Features5

5 Charge mode channels cannot be mixed with non-charge

mode channels within a connector.

Please note:The features and specifications may vary based on the software package utilized with the DECAQ

Charge Input Mode Specifications

| Interface | For piezoelectric sensors | ||

| Voltage Amplifier Range (Peak) | ±100 mV, ±1 V, ±10 V | ||

| Input Charge Range (Peak) | 1 mV/pC | ±10 000 pC | |

| 0.1 mV/pC | ±100 000 pC | ||

| 0.01 mV/pC | ±1 000 000 pC | ||

| -3 dB High Pass Frequency | 1 mV/pC | 0.16 Hz | |

| 0.1 mV/pC | 0.16 Hz | ||

| 0.01 mV/pC | 0.16 Hz | ||

| Other Sampling Rates | ±100 mV, ±1 V, ±10 V | ||

| Voltage Amplifier Range (Peak) | Available through digital LP filters and decimation | ||

| Optional First Order High-Pass Filter | -3 dB @ 1 Hz | ||

| Module Calibration | Internal amplitude and phase calibration | ||

| Protection | 1 kΩ series (inline) | ||

| Galvanic Isolation | 50 V | ||

CHX42X Charge Input Mode Specifications

Charge Input Mode Specifications continue| -3 dB Bandwidth | 1 Hz to 44.3 kHz | ||

| Maximum Sampling Rate (fs) per Channel | 102.4 kSa/s | ||

| A/D Conversion | 24-bit | ||

| Input Voltage Ranges (Peak) | ±100 mV; ±1 V; ±10 V | ||

| Sensitivity Ranges (Peak) | 1 mV/pC; 0.1 mV/pC; 0.01 mV/pC; | ||

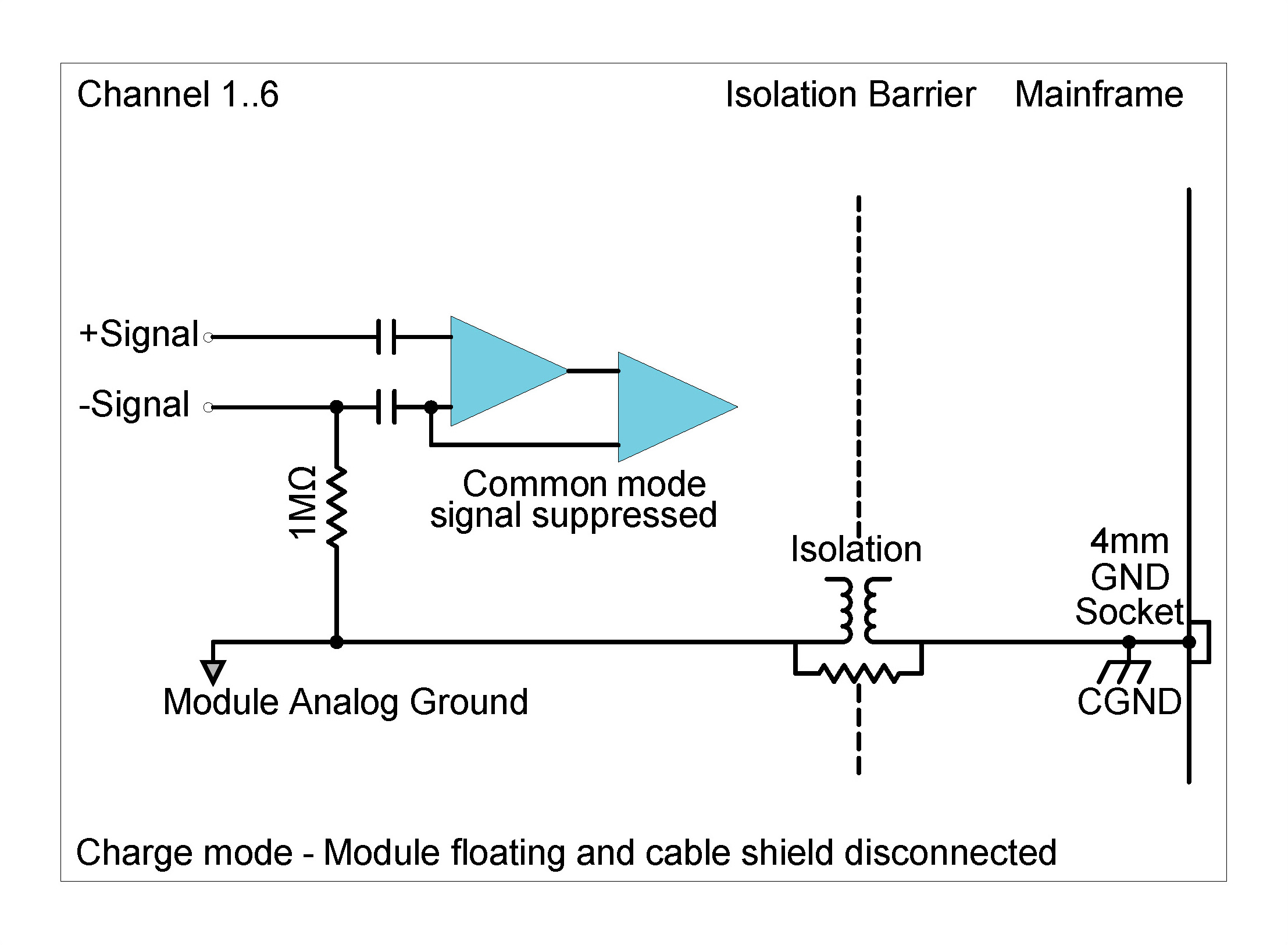

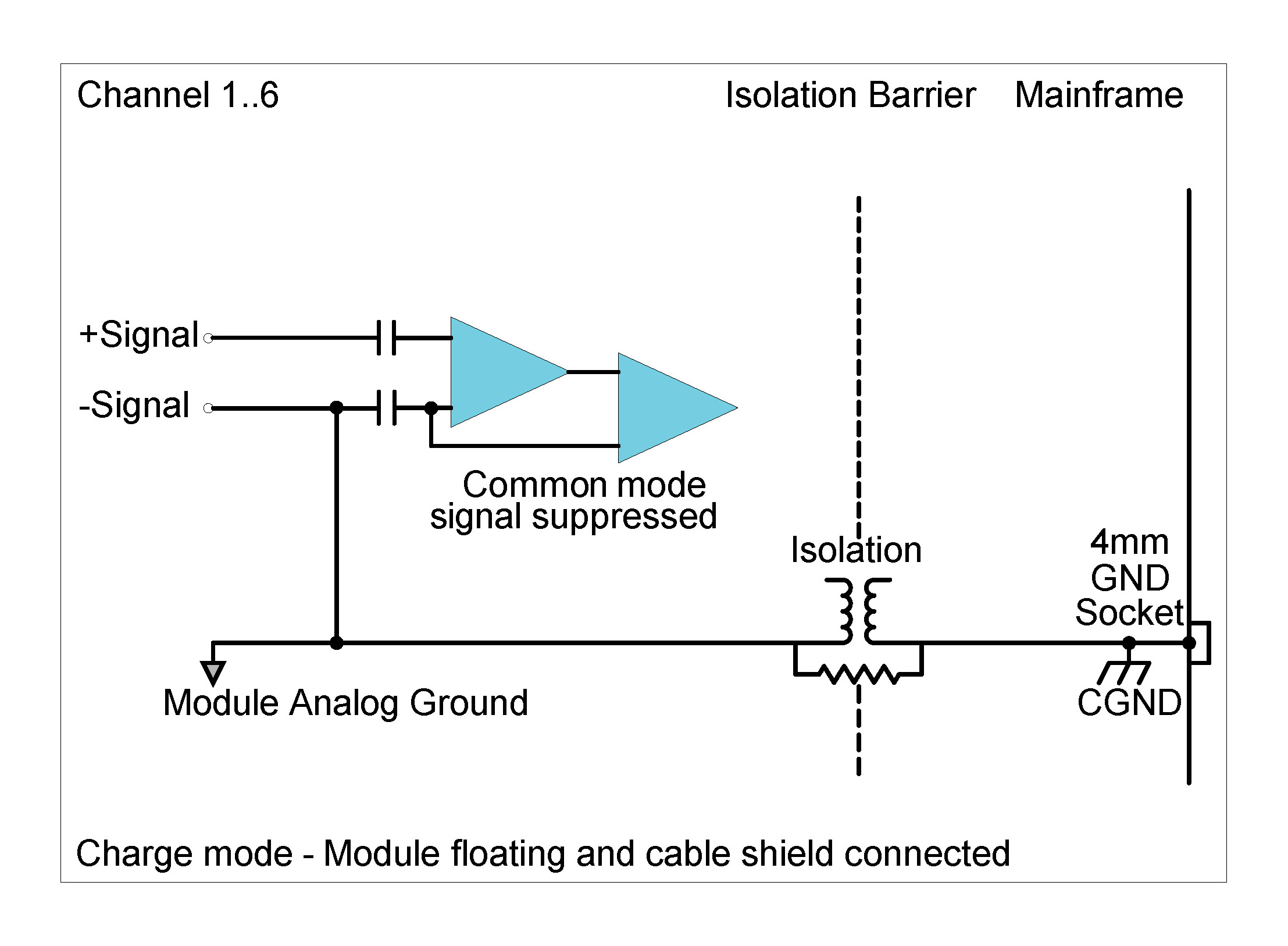

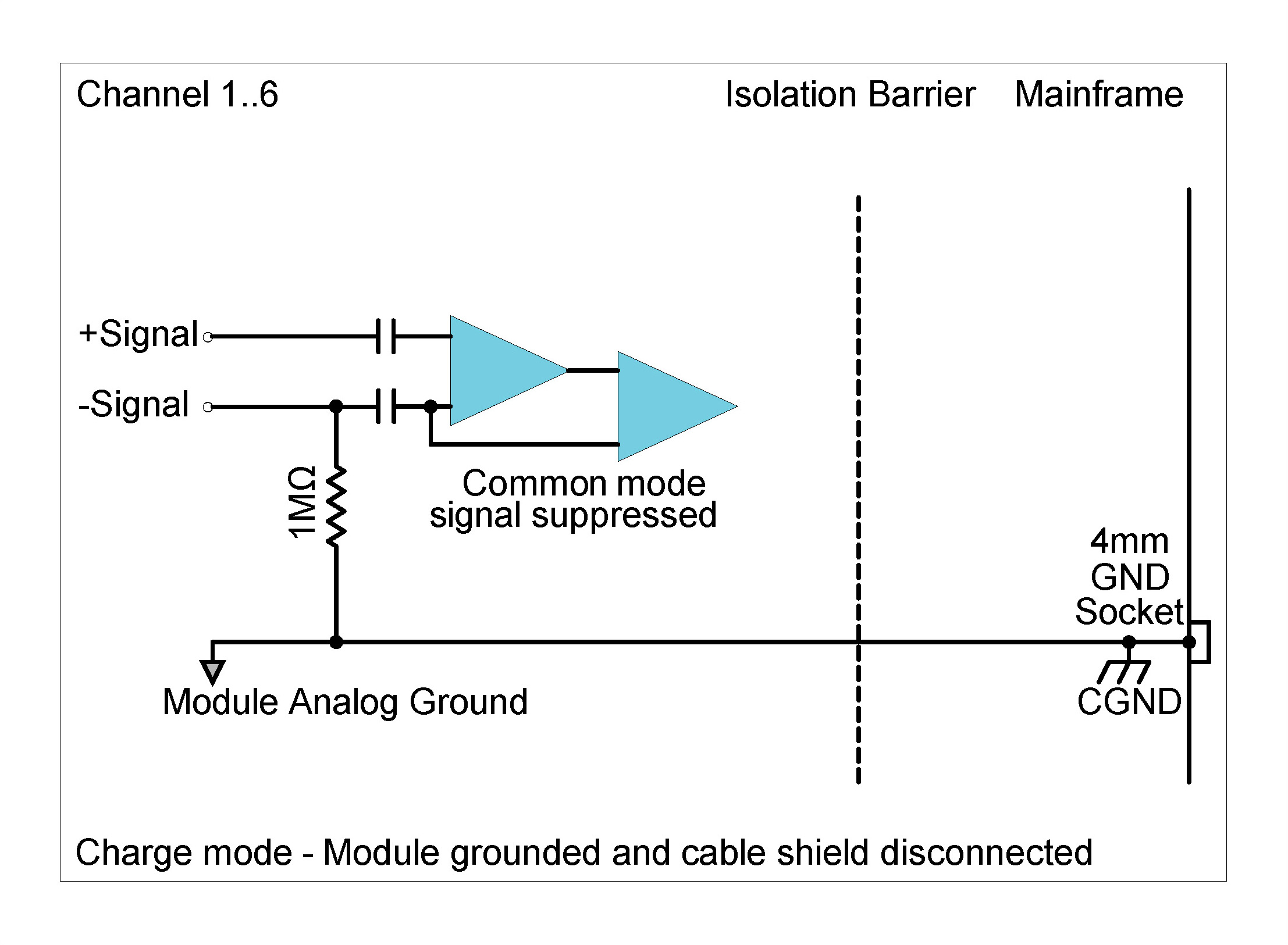

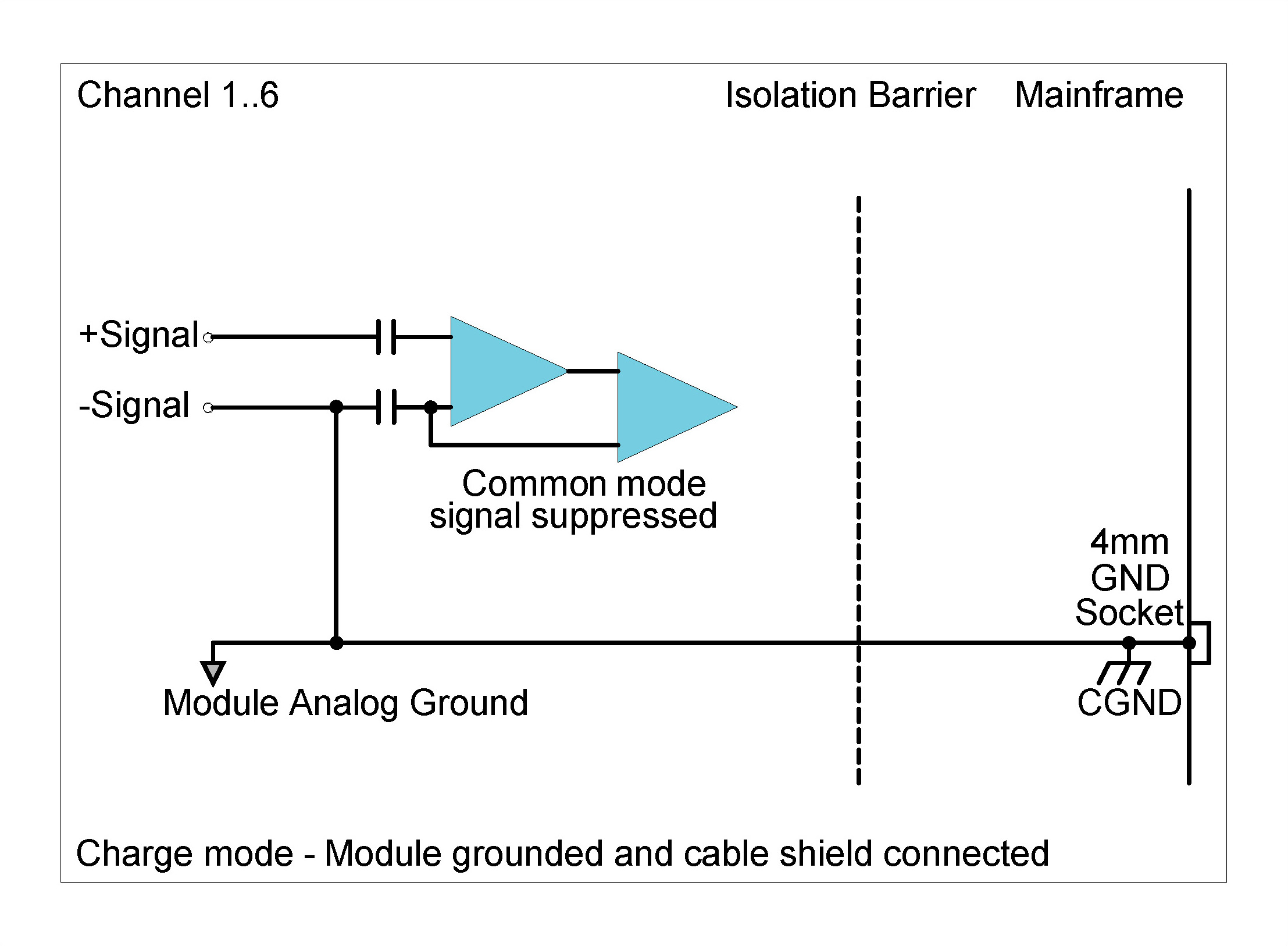

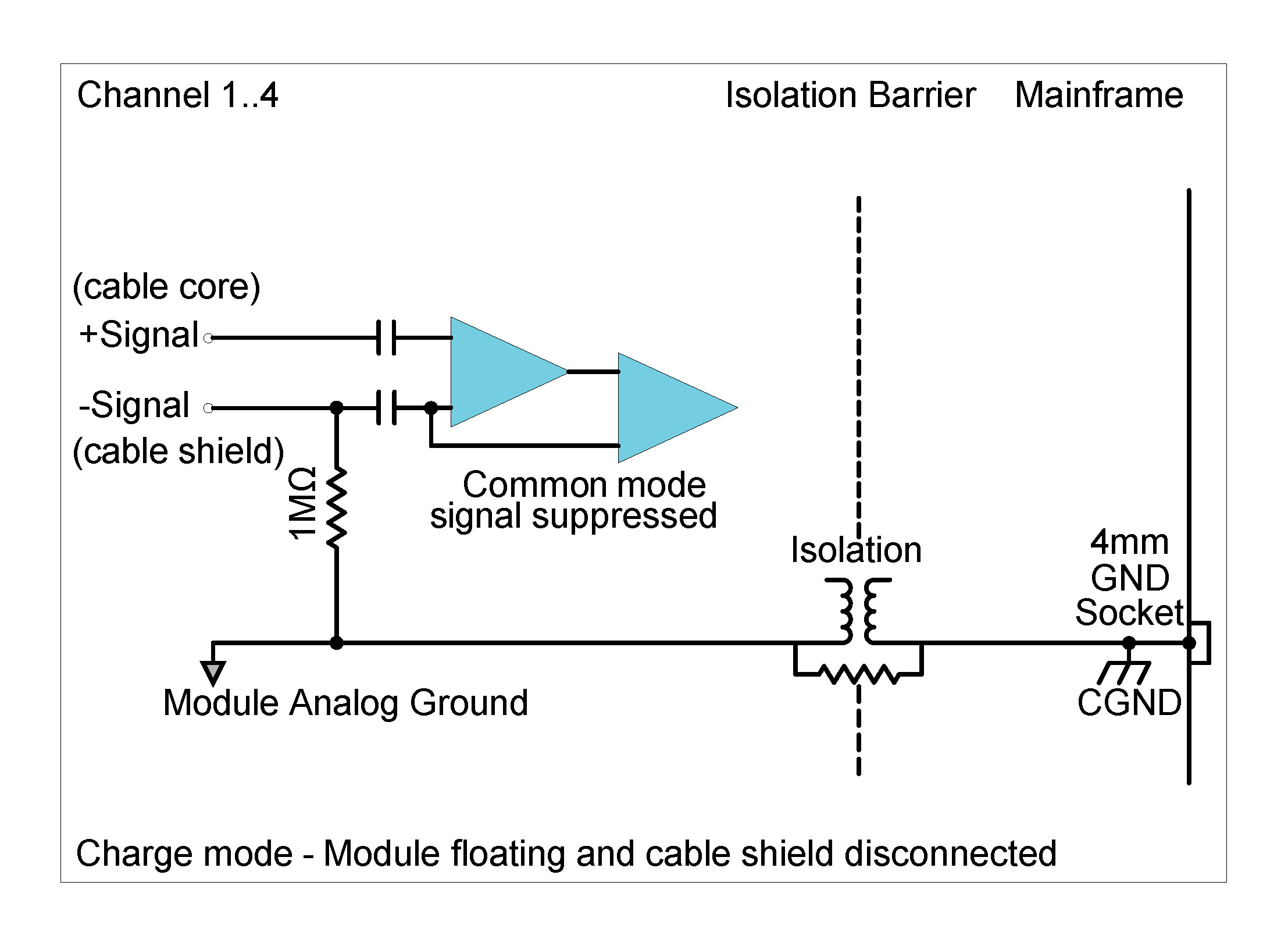

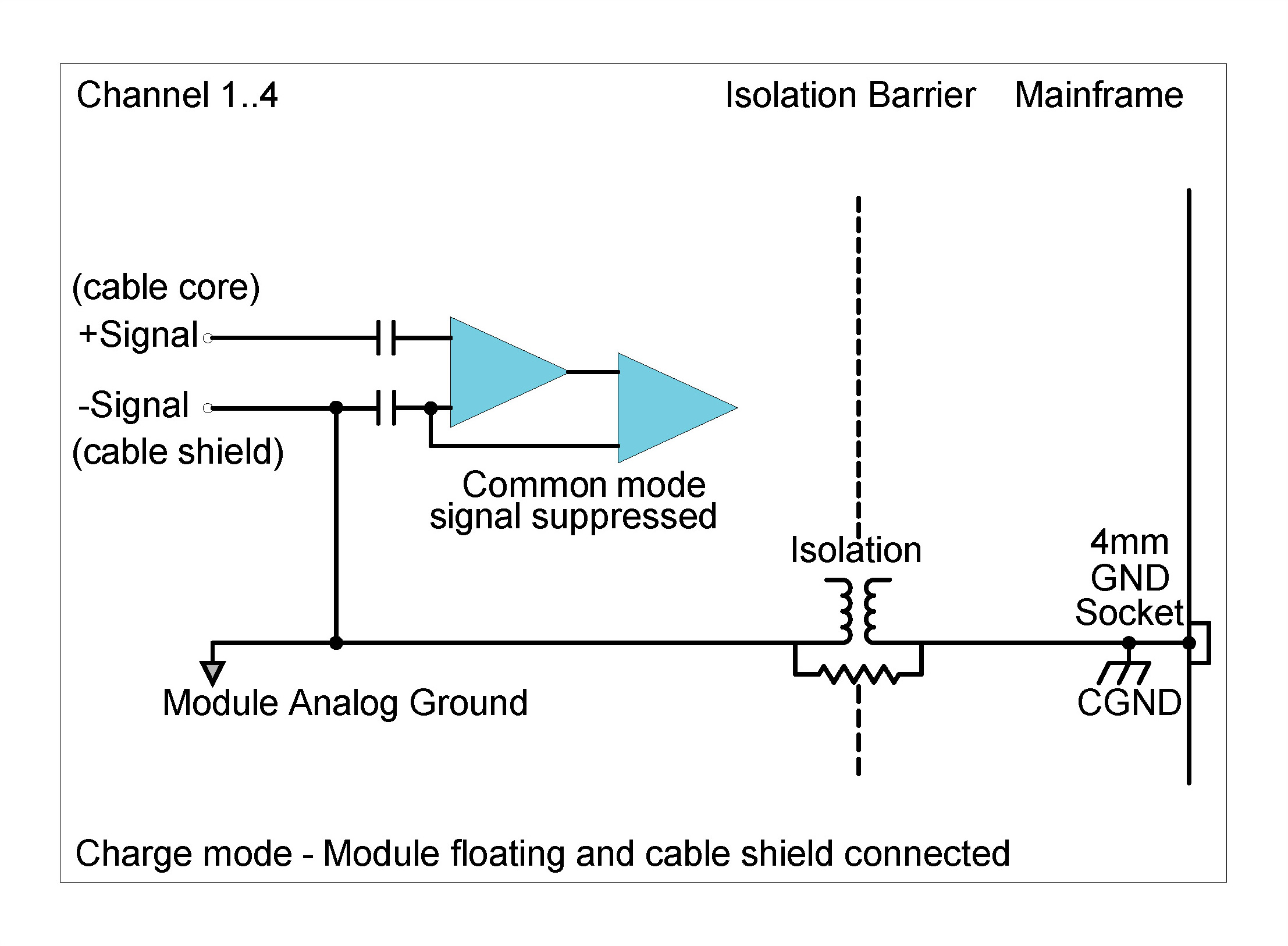

| Input Biasing Settings | Single-Ended Float | Cable Shield Disconnected | Negative signal input (cable shield) connected to floating ground through 1 MΩ |

| Cable Shield Connected | Negative signal input (cable shield) connected to floating ground | ||

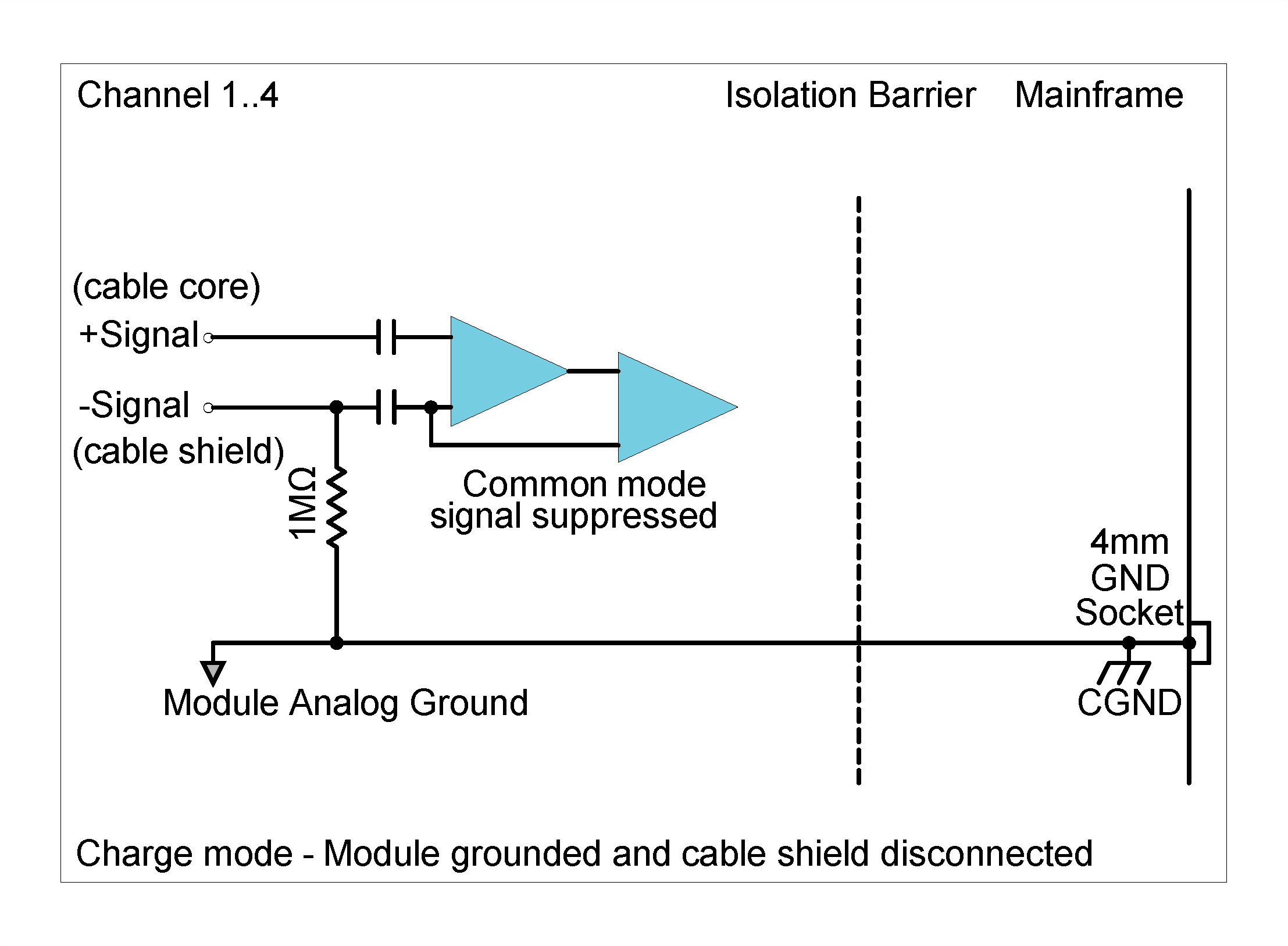

| Single-Ended GND | Cable Shield Disconnected | Negative signal input (cable shield) connected to ground through 1 MΩ | |

| Cable Shield Connected | Negative signal input (cable shield) connected to ground | ||

|

Digital Low-Pass Filter Filter scales with sampling rate |

Passband | fs x 0.433 Hz | |

| Stopband | fs x 0.499 Hz | ||

| Passband Ripple | ±0.005 dB | ||

| Stopband Attenuation | 105 dB | ||

|

Phase Accuracy for Charge Mode All channels in Charge mode |

Typical6,7 | ±0.5° at 10 kHz | |

| Phase Accuracy for Charge and Voltage Input / ICP® ModeChannels in combination of Charge and Voltage Input / ICP® mode | Typical8 | ±0.7° at 10 kHz | |

CHX42X Charge Input Mode Specifications

6Measured in 10 V range at 102.4 kSa/s with all channels in

charge mode.

7 Valid for charge mode sensitivities 1 mV/pC and 0.1

mV/pC.

8 Measured in 10 V range at 102.4 kSa/s with 3 channels in

charge mode and 3 channels in voltage input Mode

|

Charge Mode AC Voltage Accuracy Measured at 1 kHz |

Input Range(Peak) | Sensitivity Range | % Range | ||

| ±100 mV | 0.01 mV/pC | 3.0 % | |||

| 0.1 mV/pC | 3.1 % | ||||

| 1 mV/pC | 2.7 % | ||||

| ±1 V | 0.01 mV/pC | 2.5 % | |||

| 0.1 mV/pC | 2.7 % | ||||

| 1 mV/pC | 1.9 % | ||||

| ±10 V | 0.01 mV/pC | 2.5 % | |||

| 0.1 mV/pC | 2.6 % | ||||

| 1 mV/pC | 2.1 % | ||||

|

Charge Mode Noise Measured open input with 1 mV/pC sensitivity range |

Input Range (Peak) | Guaranteed | Typical | ||

| 10 Hz to 22 kHz | ±100 mV | < 6.0 µVrms | < 5.0 µVrms | ||

| 10 Hz to 44.3 kHz | < 10 µVrms | < 8.0 µVrms | |||

| 10 Hz to 22 kHz | ±1 V | < 7.0 µVrms | < 6.5 µVrms | ||

| 10 Hz to 44.3 kHz | < 14.9 µVrms | < 12.1 µVrms | |||

| 10 Hz to 22 kHz | ±10 V | < 40 µVrms | < 35 µVrms | ||

| 10 Hz to 44.3 kHz | < 125 µVrms | < 89 µVrms | |||

| Charge Mode Noise Measured open input with 0.1 mV/pC sensitivity range | Input Range (Peak) | Guaranteed | Typical | ||

| 10 Hz to 22 kHz | ±100 mV | < 6.0 µVrms | < 5.5 µVrms | ||

| 10 Hz to 44.3 kHz | < 8.0 µVrms | < 7.5 µVrms | |||

| 10 Hz to 22 kHz | ±1 V | < 7.5 µVrms | < 6.5 µVrms | ||

| 10 Hz to 44.3 kHz | < 9.0 µVrms | < 8.5 µVrms | |||

| 10 Hz to 22 kHz | ±10 V | < 90 µVrms | < 65 µVrms | ||

| 10 Hz to 44.3 kHz | < 140 µVrms | < 105 µVrms | |||

|

Charge Mode Noise Measured open input with 0.01 mV/pC sensitivity range |

Input Range (Peak) | Guaranteed | Typical | ||

| 10 Hz to 22 kHz | ±100 mV | < 10 µVrms | < 9.5 µVrms | ||

| 10 Hz to 44.3 kHz | < 8.0 µVrms | < 7.0 µVrms | |||

| 10 Hz to 22 kHz | ±1 V | < 8.5 µVrms | < 7.5 µVrms | ||

| 10 Hz to 44.3 kHz | < 9.0 µVrms | < 8.5 µVrms | |||

| 10 Hz to 22 kHz | ±10 V | < 45 µVrms | < 35 µVrms | ||

| 10 Hz to 44.3 kHz | < 50 µVrms | < 40 µVrms | |||

| Charge Mode Dynamic Range9Measured from 50 Hz to 0.40 x fs | Input Range (Peak) | Typical | |||

| 0.01 mV/pC sensitivity range | 0.1 mV/pC sensitivity range | 1 mV/pC sensitivity range | |||

| ±100 mV | > 110 dB | > 110 dB | > 110 dB | ||

| ±1 V | > 130 dB | > 130 dB | > 130 dB | ||

| ±10 V | > 130 dB | > 130 dB | > 130 dB | ||

| Charge Mode Amplitude FlatnessMeasured from 50 Hz to 0.40 x fs | Sampling Rate (fs) | Input Range (Peak) | Attenuation (input signal level 100% of full range) | ||

| 0.01 mV/pC sensitivity range | 0.1 mV/pC sensitivity range | 1 mV/pC sensitivity range | |||

| 51.2 kSa/s | ±100 mV | − 0.35 dB | − 0.24 dB | − 0.48 dB | |

| 102.4 kSa/s | − 0.45 dB | − 0.77 dB | − 1.45 dB | ||

| 51.2 kSa/s | ±1 V | − 0.18 dB | − 0.22 dB | − 0.39 dB | |

| 102.4 kSa/s | − 0.76 dB | − 0.76 dB | − 0.96 dB | ||

| 51.2 kSa/s | ±10 V | − 0.22 dB | − 0.21 dB | − 0.41 dB | |

| 102.4 kSa/s | − 0.75 dB | − 0.80 dB | − 0.99 dB | ||

CHX42X Charge Input Mode Specifications 9 Dynamic range calculated at sampling rate of 51.2 kSa/s, with a 4096-point FFT.

Specification number: SP200300, Release 1.3. Module settings and measurement conditions that were used during specification measurements are available on request.

Functionality per Channel

Connector layout

On the front panel of the CHS42X a connector layout description can be found.

Connectors marked with an  will accept ICP® as

well as voltage input signals. Connectors marked with a

will accept ICP® as

well as voltage input signals. Connectors marked with a  are capable of accepting charge signals.

are capable of accepting charge signals.

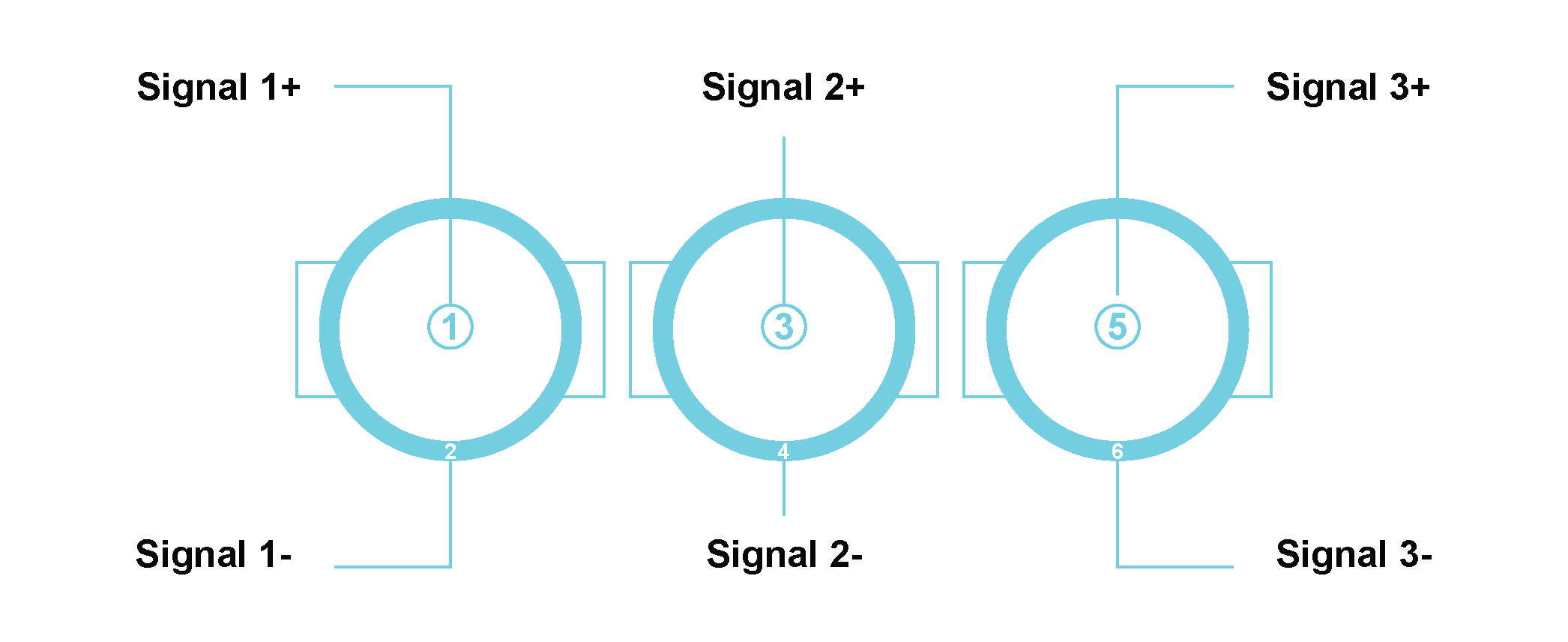

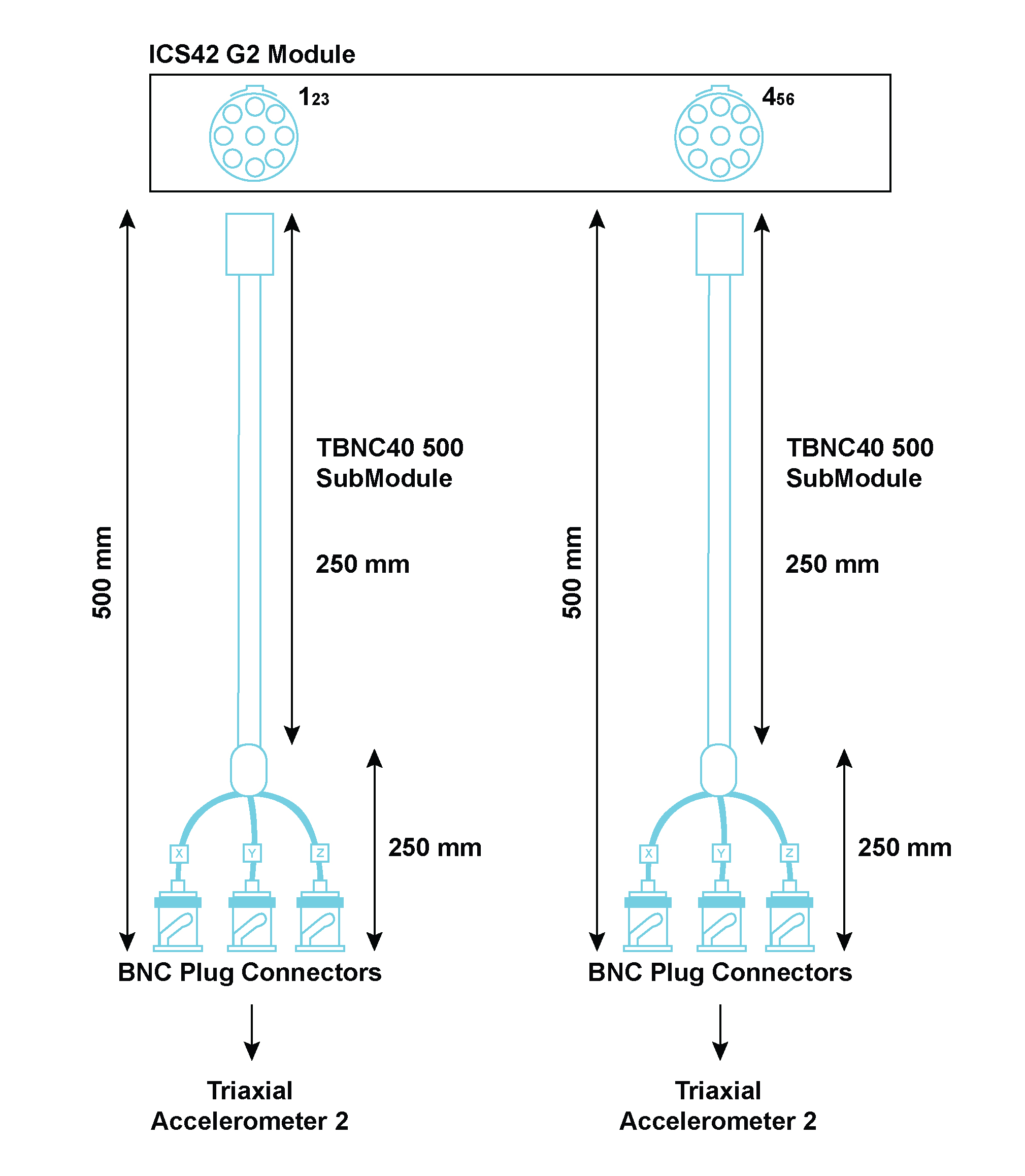

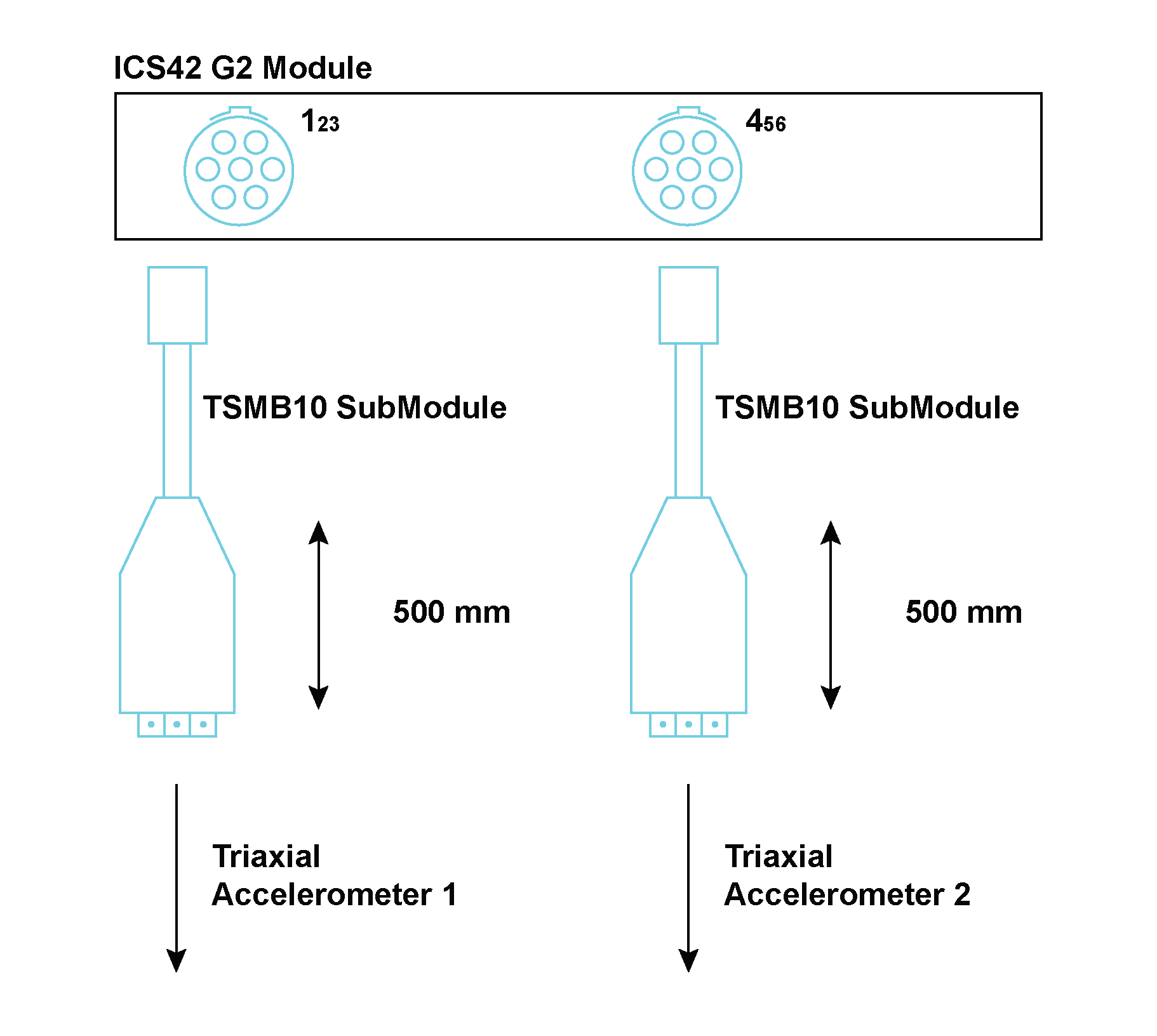

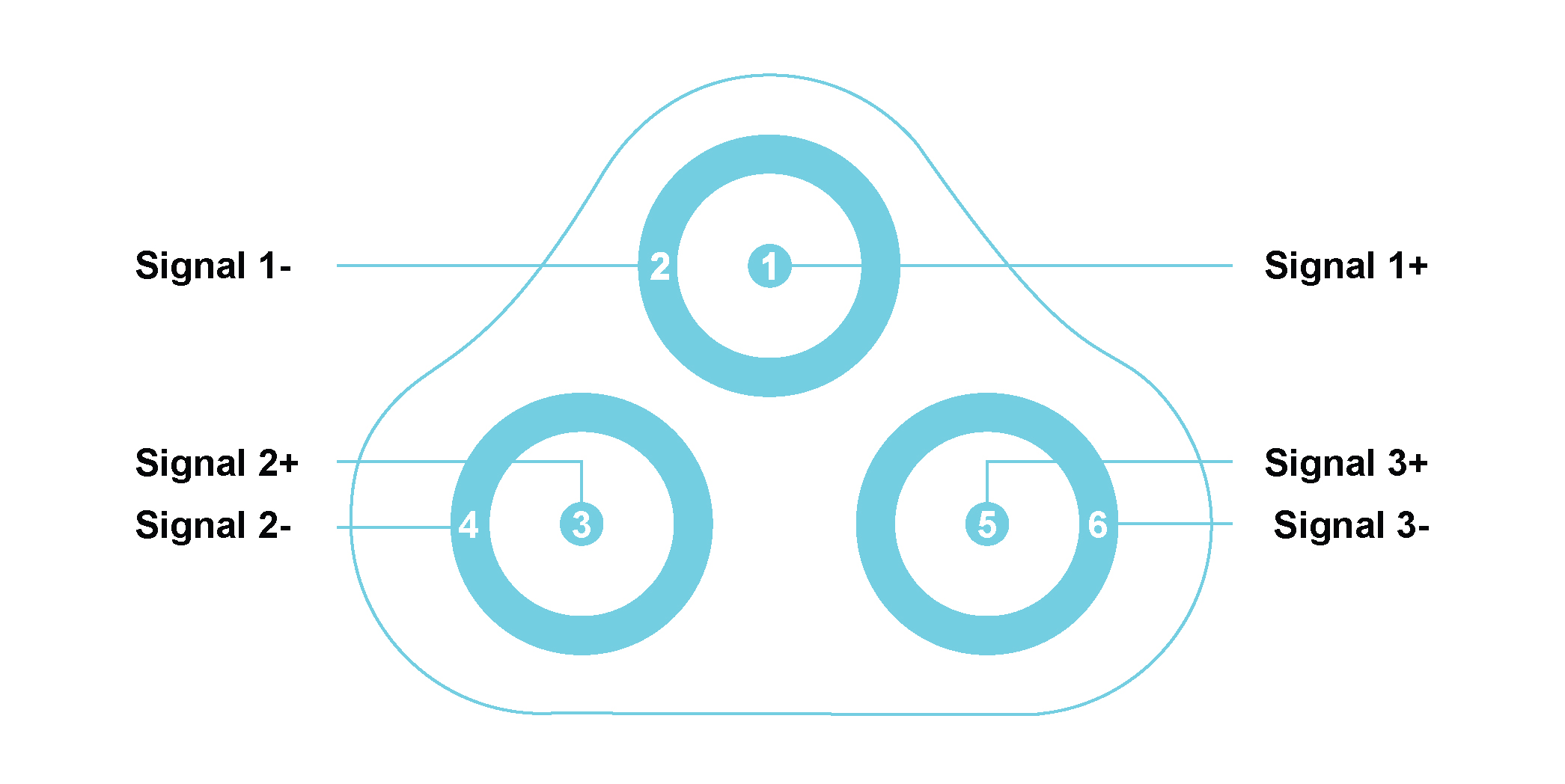

ICP® Accelerometer Connections per Module

The CHS42X can accept inputs from single ICP® accelerometers as well as triaxial ICP® accelerometers. The connectors on the front panel are ideally designed to connect to two triaxial sensors per Module. The LEMO® 9-way EHG.0B connectors Module pin definition indicates where the signal connections of each X, Y and Z and the common return of the triaxial sensor can be connected.

Grounding options ALI mode (Voltage Input mode)

There are four ALI mode grounding options available on the CHS42X:

Grounding Diagrams: ALI mode (Voltage input mode)

Although each channel in the CHS42X can be set individually as to its grounding type, enabling the ground option on any one channel will cause the isolation barrier of the module to be bridged (i.e., on all six channels AGNDM will be directly connected to CGND).

Grounding options Charge mode

The CHS42X offers 4 grounding options. The grounding options are provided for reducing electromagnetic interference (EMI) that might be present on the sensor cables.

| Module | Cable Shield Connected | Industry Name | Shield to Chassis |

|---|---|---|---|

| *Floating | *No | Floating | 1 MΩ + 10 kΩ |

| Floating | Yes | - | 10 kΩ |

| Grounded | No | - | 1 MΩ |

| Grounded | Yes | Single-Ended | ~20 Ω |

CHS42X Module charge mode grounding options

*Default setting on Module startup. This combination provides a path for Electrostatic Discharge (ESD) to slowly discharge and will provide some protection against rapid ESD events that could damage the sensitive charge inputs.

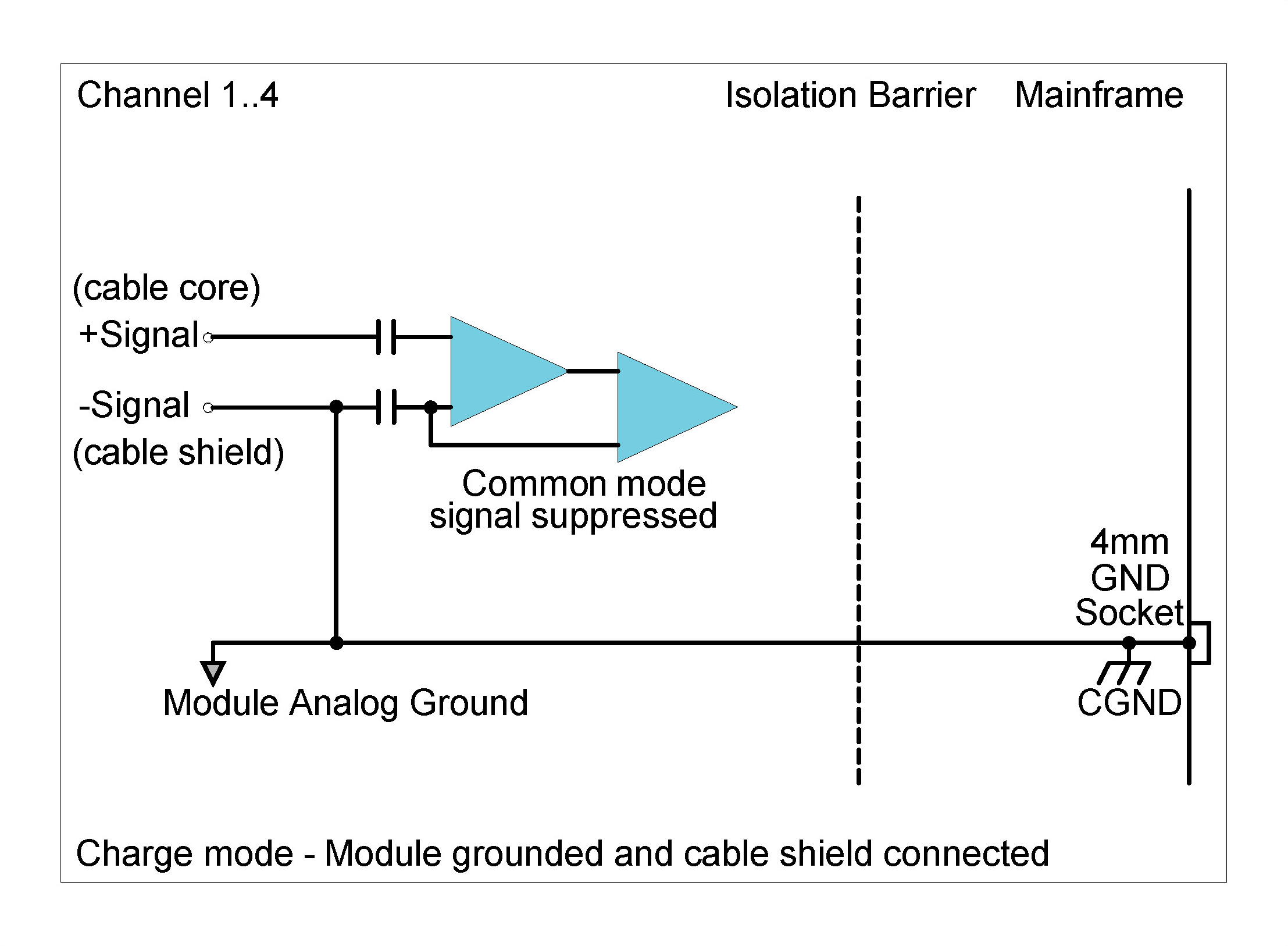

Grounding Diagrams: Charge mode

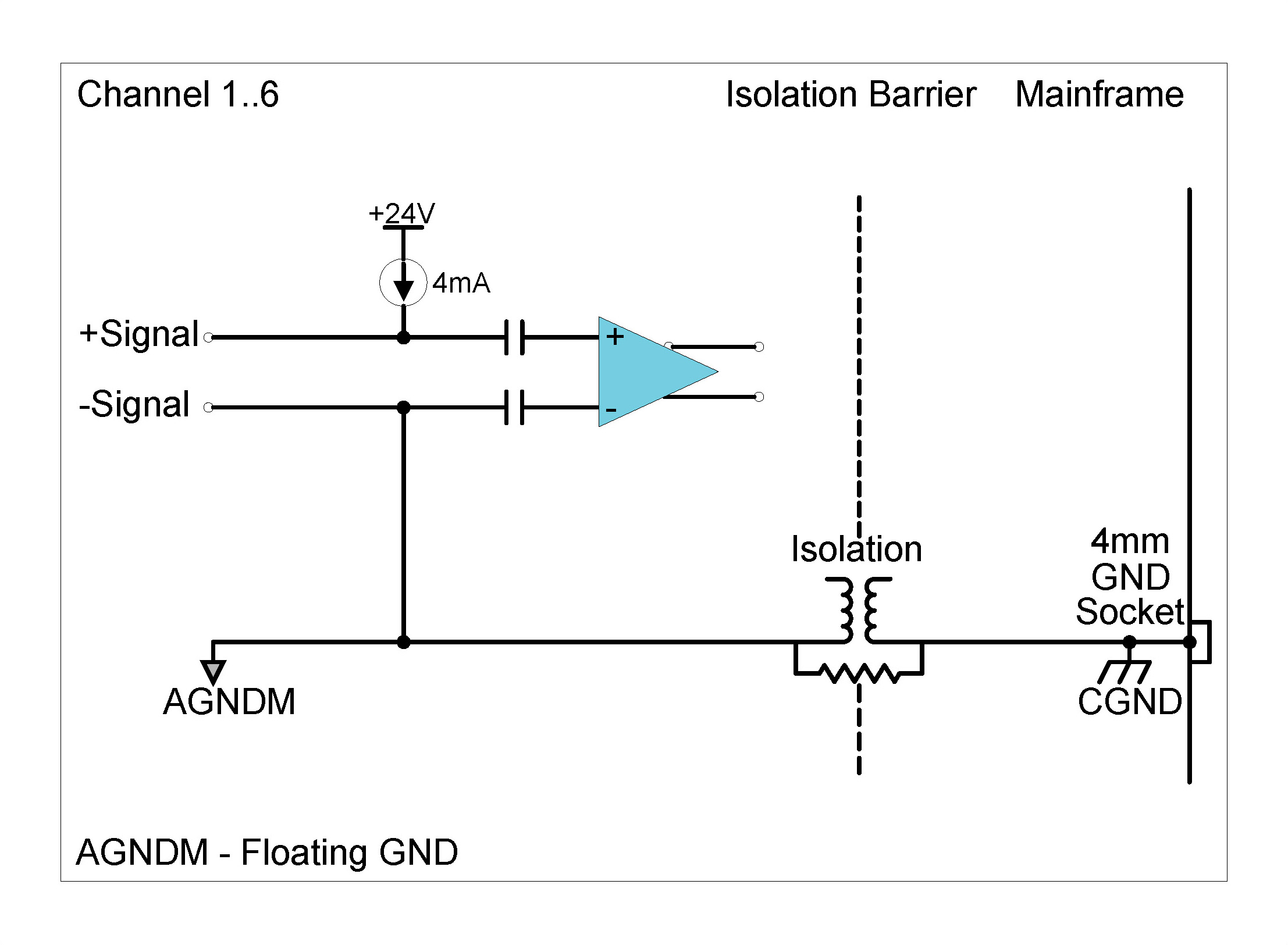

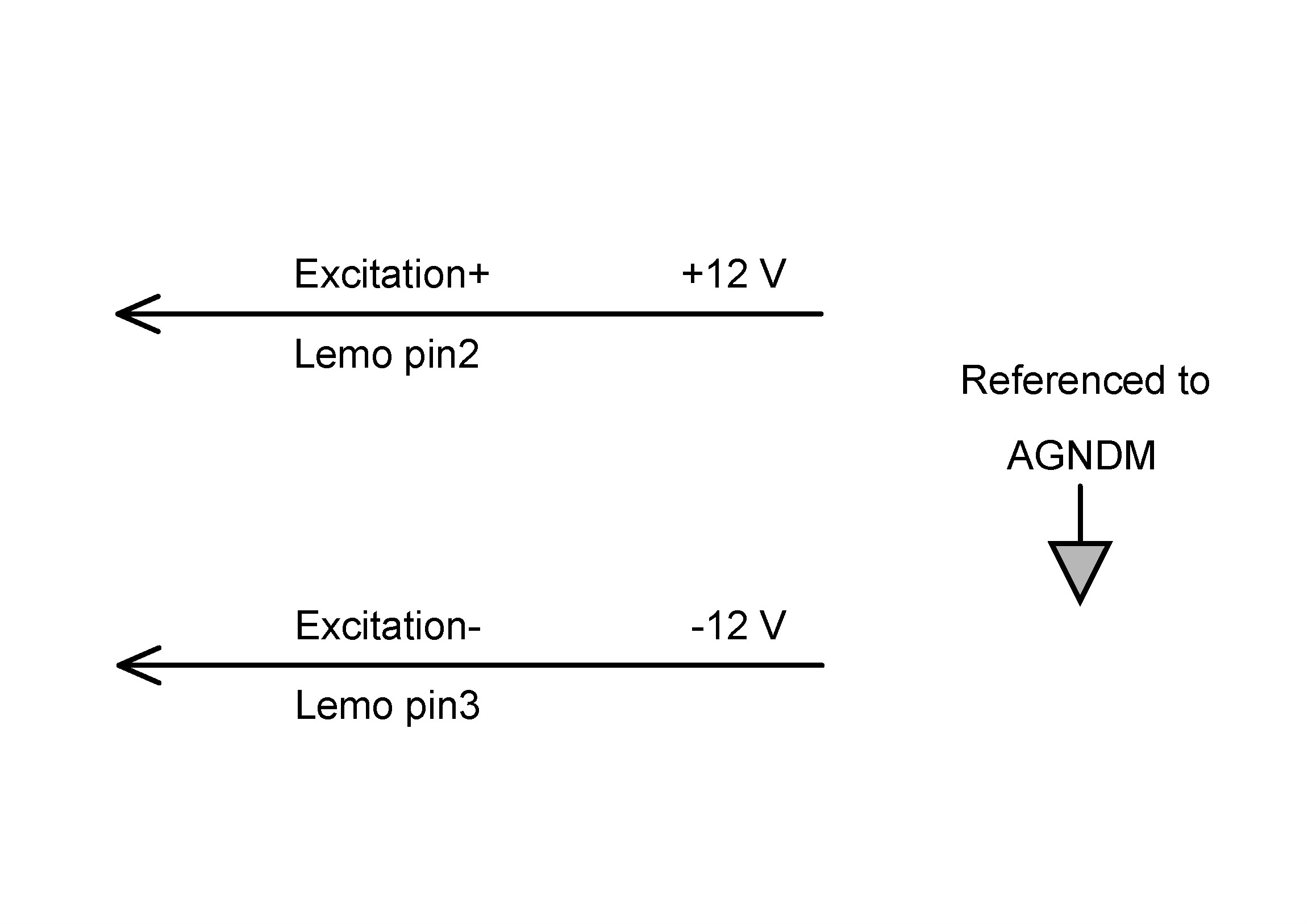

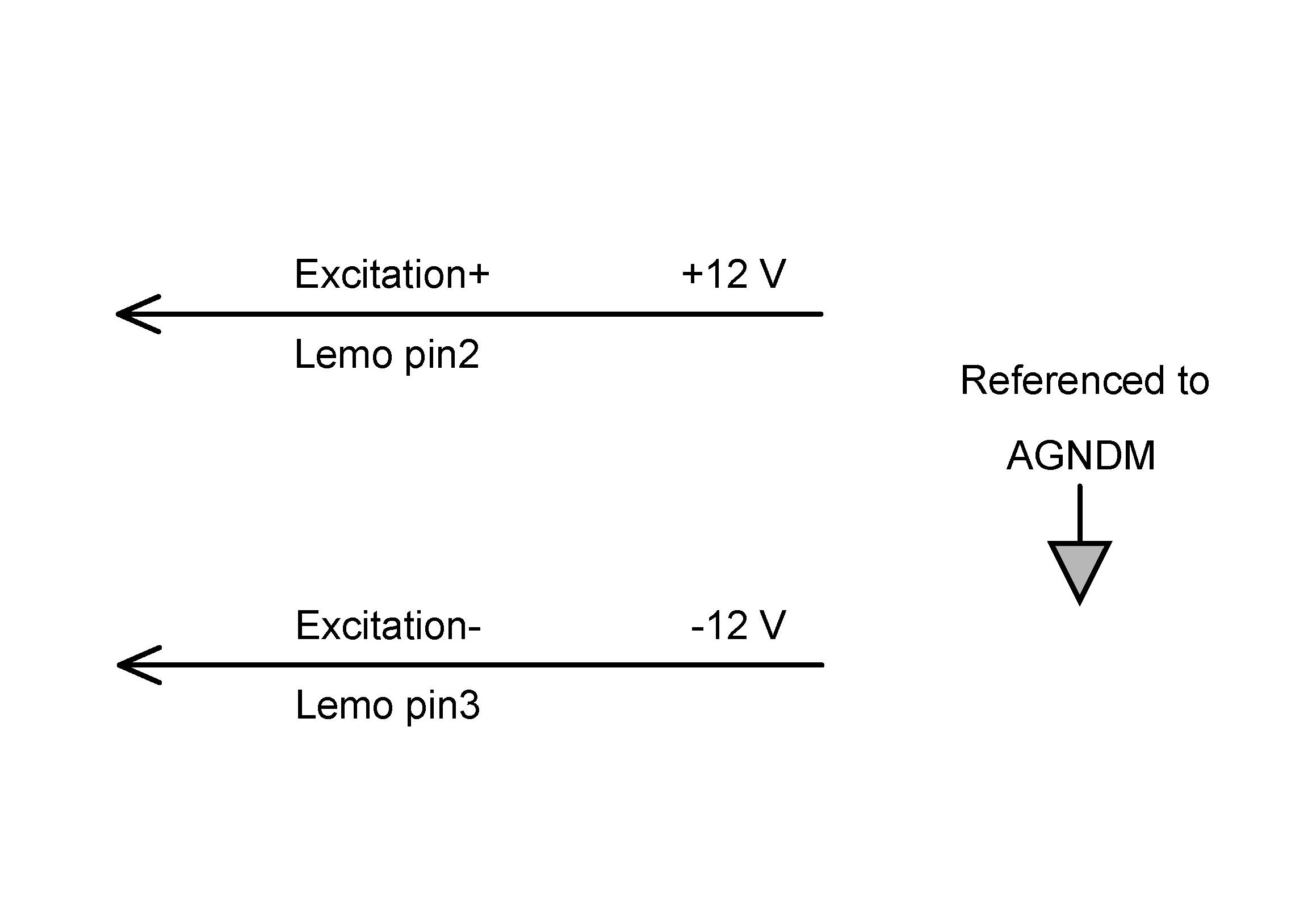

Excitation Diagrams: ICP® Mode

The CHS42X can facilitate an ICP® input mode with a 4 mA current excitation. The Biasing settings are independent of the grounding options. The following table shows the different possible settings for the ICS42 Module in ICP® input mode:

| Excitation voltage | Biasing settings | Grounding options |

|---|---|---|

| 24 V (Asymmetrical) | Differential or single-ended | Ground or Floating ground |

CHS42X Module Settings in ICP® input mode with 4 mA current excitation

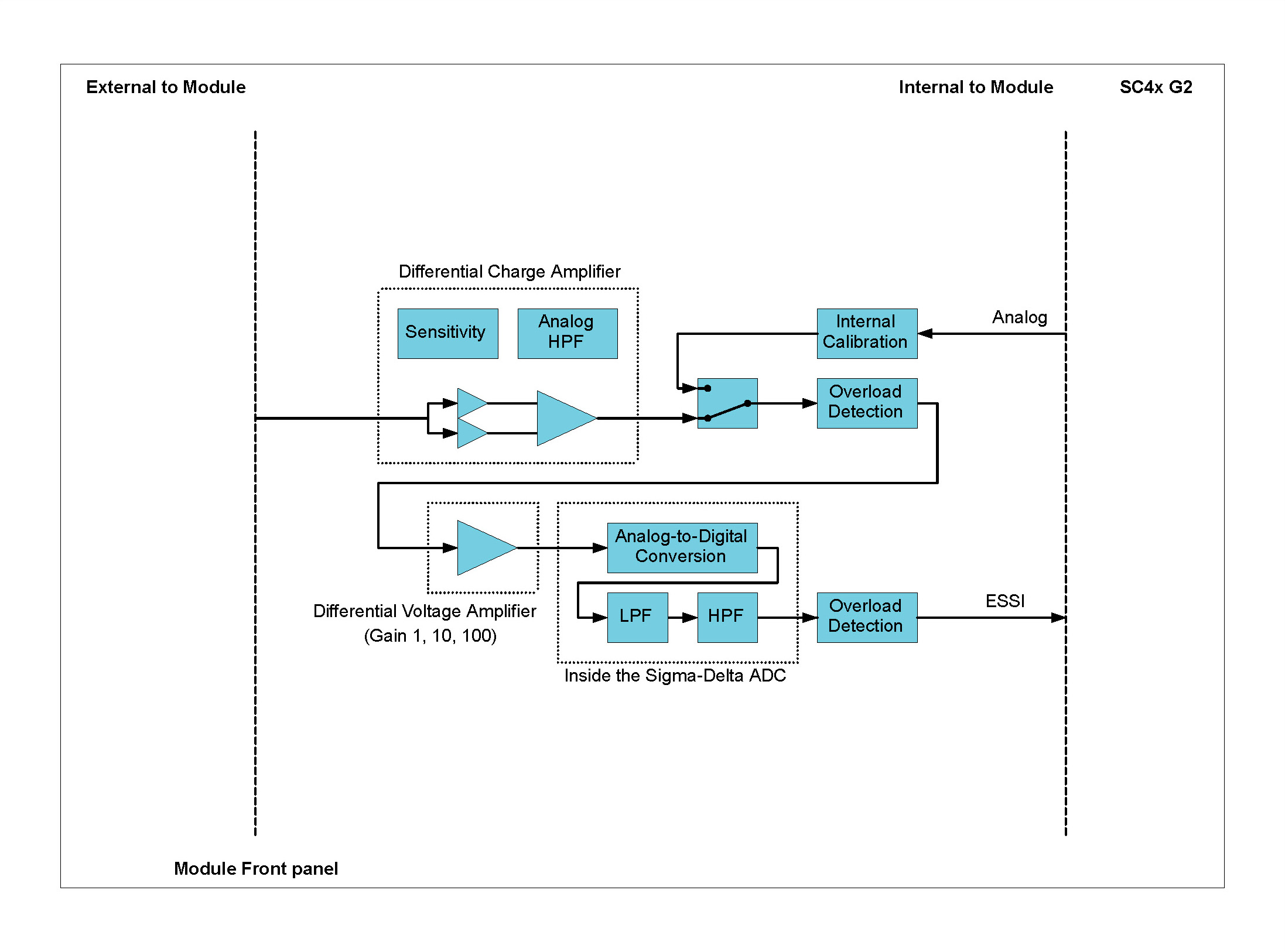

Description

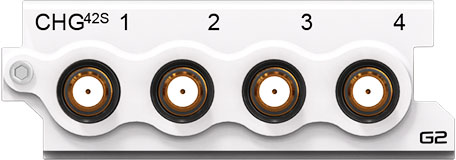

The CHG42S Module has 4 independent input channels for Quartz or Piezoelectric Ceramic sensors. These sensors are typically used when improved signal performance such as low noise and low distortion is required or where high temperature or nuclear radiation prevents the use of ICP® based sensors. Various grounding options allow for low noise measurements regardless of external grounding constraints. The Module can be used:

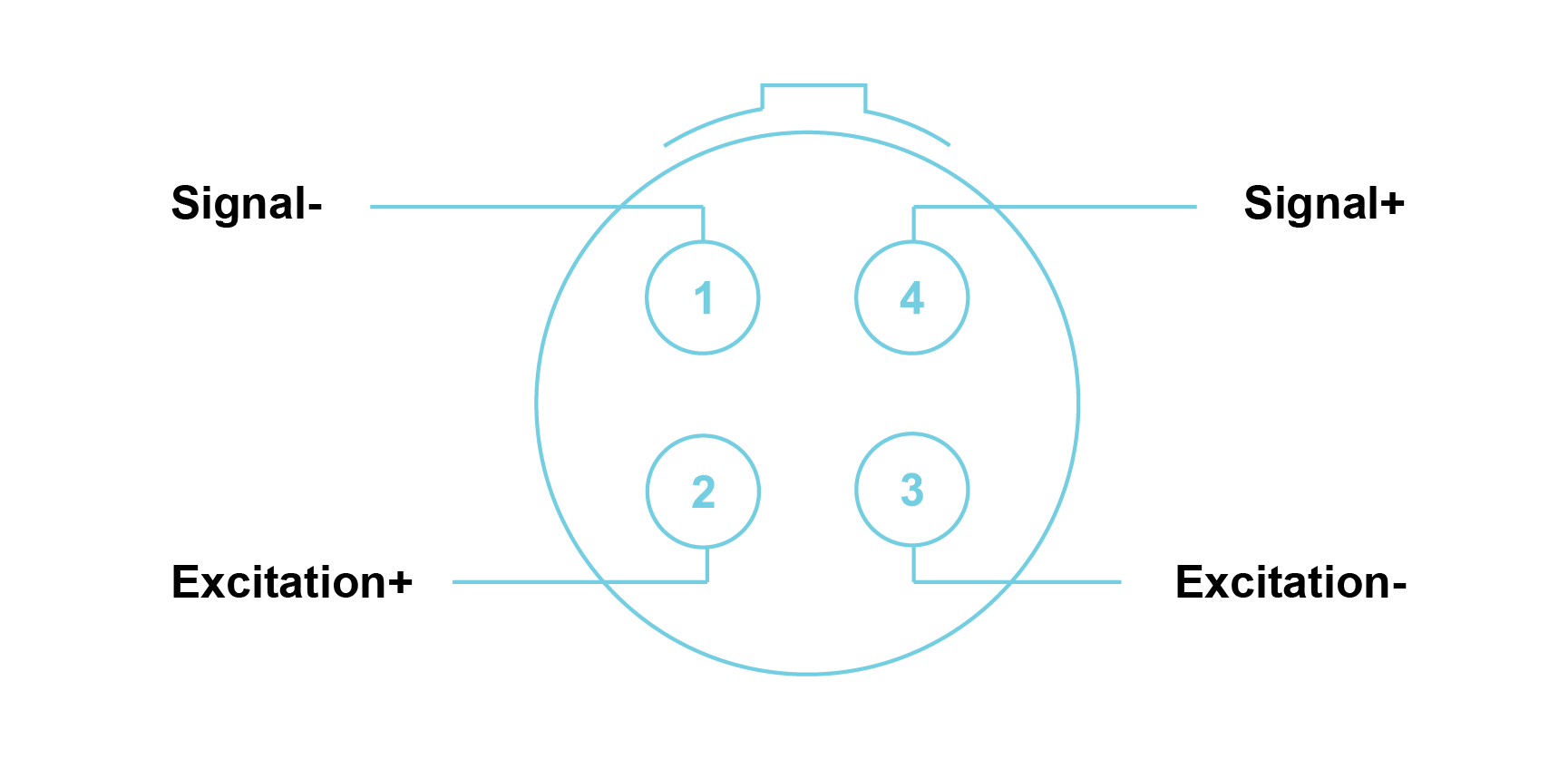

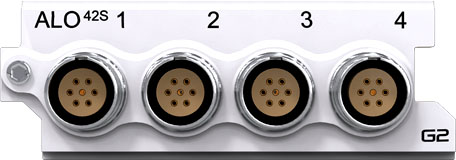

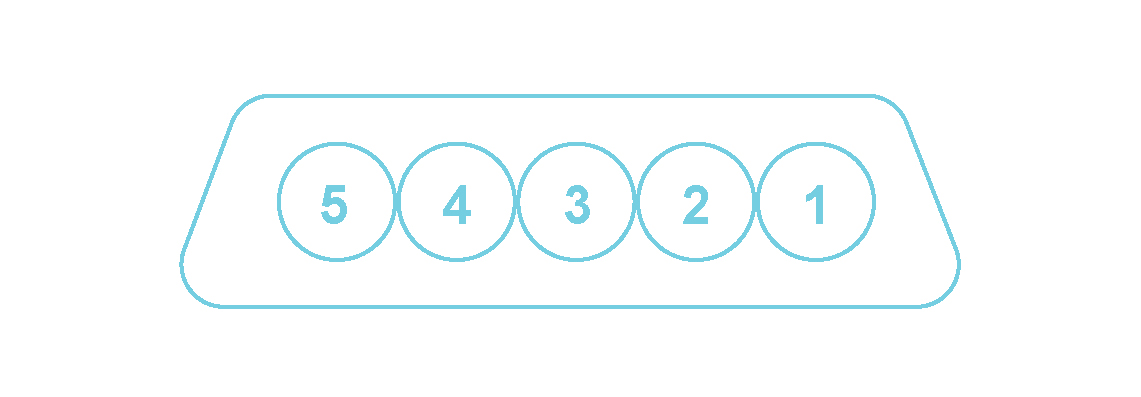

| Front Panel | Connector Information and Pin Definitions |

|---|---|

|

|

CHG42S with 10-32 Microdot connectors Module Pin Definition when looking into the front panel’s connector or at the rear of the cable’s connector

ESD WARNING

The CHG42S Module inputs are sensitive to ESD damage. Always take care to discharge any additional static electricity that might have built up on a cable and connector before making contact with the CHG42S Module.

Features

Please note:The features and specifications may

vary based on the software package utilized with the

DECAQ

CHG42S Specifications

| Interface | For piezoelectric sensors | ||

| Voltage Amplifier Range (Peak) | ±100 mV, ±1 V, ±10 V | ||

| Input Charge Range (Peak) | 0.1 mV/pC | ±100,000 pC | |

| 1 mV/pC | ±10,000 pC | ||

| 10 mV/pC | ±1,000 pC | ||

| -3 dB High-Pass Frequency | 0.1 mV/pC | 0.016 Hz | |

| 1 mV/pC | 0.016 Hz | ||

| 10 mV/pC | 0.16 Hz | ||

| Other Sampling Rates | Available through digital LP filters and decimation | ||

| Optional Programmable Digital IIR Filter |

Bandpass/stop : 6 dB/octave High/Low-pass : 12 dB/octave |

||

| Optional First Order High-Pass Filter | -3 dB @ 1 Hz | ||

| Module Calibration | Internal amplitude calibration | ||

| Protection | 1 kΩ series (inline) | ||

| Galvanic Isolation | 50 V | ||

| Bandwidth | DC to 90 kHz | ||

| Maximum Sampling Rate (fs) per Channel | 204.8 kSa/s | ||

| A/D Conversion | 24-bit | ||

| Data Transfer | 16/24-bit | ||

| Input Voltage Ranges (Peak) | ±100 mV; ±1 V; ±10 V | ||

| Sensitivity Ranges (Peak) | 0.1 mV/pC; 1 mV/pC; 10 mV/pC | ||

| Input Biasing Settings | Single-Ended Float | Cable Shield Disconnected | Negative signal input (cable shield) connected to floating ground through 1 MΩ |

| Cable Shield Connected | Negative signal input (cable shield) connected to floating ground | ||

| Single-Ended GND | Cable Shield Disconnected | Negative signal input (cable shield) connected to floating ground | |

| Cable Shield Connected | Negative signal input (cable shield) connected to ground | ||

|

Digital Low-Pass Filter Filter scales with sampling rate |

Passband | fs x 0.45 Hz | |

| Stopband | fs x 0.55 Hz | ||

| Passband Ripple | ±0.005 dB | ||

| Stopband Attenuation | 100 dB | ||

|

Phase Accuracy Channels in similar range |

Typical1 | < 0.5° at 10 kHz | |

1 Measured in 10 V range at 204.8 kSa/s

|

AC Voltage Accuracy Measured at 1 kHz |

Input Range (Peak) | Sensitivity Range | % Range Typical | ||

| ±100 mV | 0.1 mV/pC | 3.1 % | |||

| 1 mV/pC | 2.7 % | ||||

| 10 mV/pC | 2.7 % | ||||

| ±1 V | 0.1 mV/pC | 2.7 % | |||

| 1 mV/pC | 1.9 % | ||||

| 10 mV/pC | 2.5 % | ||||

| ±10 V | 0.1 mV/pC | 2.6 % | |||

| 1 mV/pC | 2.1 % | ||||

| 10 mV/pC | 2.6 % | ||||

|

Noise Measured open input with 0.1 mV/pC sensitivity range |

Input Range (Peak) | Guaranteed | Typical | ||

| 10 Hz to 23 kHz | ±100 mV | < 50 µVrms | < 46 µVrms | ||

| 10 Hz to 49 kHz | < 73 µVrms | < 68 µVrms | |||

| 10 Hz to 90 kHz | < 160 µVrms | < 144 µVrms | |||

| 10 Hz to 23 kHz | ±1 V | < 109 µVrms | < 81 µVrms | ||

| 10 Hz to 49 kHz | < 140 µVrms | < 116 µVrms | |||

| 10 Hz to 90 kHz | < 1085 µVrms | < 924 µVrms | |||

| 10 Hz to 23 kHz | ±10 V | < 460 µVrms | < 409 µVrms | ||

| 10 Hz to 49 kHz | < 1175 µVrms | < 859 µVrms | |||

| 10 Hz to 90 kHz | < 10816 µVrms | < 9114 µVrms | |||

|

Noise Measured open input with 1 mV/pC sensitivity range |

Input Range (Peak) | Guaranteed | Typical | ||

| 10 Hz to 23 kHz | ±100 mV | < 8.8 µVrms | < 6.2 µVrms | ||

| 10 Hz to 49 kHz | < 10 µVrms | < 8 µVrms | |||

| 10 Hz to 90 kHz | < 17.8 µVrms | < 15.3 µVrms | |||

| 10 Hz to 23 kHz | ±1 V | < 11.4 µVrms | < 8.5 µVrms | ||

| 10 Hz to 49 kHz | < 14.9 µVrms | < 12.1 µVrms | |||

| 10 Hz to 90 kHz | < 107 µVrms | < 92 µVrms | |||

| 10 Hz to 23 kHz | ±10 V | < 46 µVrms | < 41 µVrms | ||

| 10 Hz to 49 kHz | < 125 µVrms | < 89 µVrms | |||

| 10 Hz to 90 kHz | < 1077 µVrms | < 910 µVrms | |||

|

Noise Measured open input with 10 mV/pC sensitivity range |

Input Range (Peak) | Guaranteed | Typical | ||

| 10 Hz to 23 kHz | ±100 mV | < 9.1 µVrms | < 4.4 µVrms | ||

| 10 Hz to 49 kHz | < 9 µVrms | < 4.6 µVrms | |||

| 10 Hz to 90 kHz | < 9.1 µVrms | < 5.1 µVrms | |||

| 10 Hz to 23 kHz | ±1 V | < 8.9 µVrms | < 4.4 µVrms | ||

| 10 Hz to 49 kHz | < 8.8 µVrms | < 4.6 µVrms | |||

| 10 Hz to 90 kHz | < 8.2 µVrms | < 7.3 µVrms | |||

| 10 Hz to 23 kHz | ±10 V | < 8.6 µVrms | < 5.8 µVrms | ||

| 10 Hz to 49 kHz | < 13.2 µVrms | < 9.3 µVrms | |||

| 10 Hz to 90 kHz | < 108 µVrms | < 91 µVrms | |||

|

Charge Mode Dynamic Range2 Measured from 50 Hz to 0.40 x fs |

Input Range (Peak) | Typical | |||

| 0.01 mV/pC sensitivity range | 0.1 mV/pC sensitivity range | 1 mV/pC sensitivity range | |||

| ±100 mV | > 110 dB | > 110 dB | > 90 dB | ||

| ±1 V | > 130 dB | > 130 dB | > 110 dB | ||

| ±10 V | > 130 dB | > 130 dB | > 130 dB | ||

|

Amplitude Flatness Relative to 1 kHz Measured up to 0.39 x fs |

Sampling Rate (fs) | Input Range (Peak) |

Attenuation Input signal level 100 % of full range |

||

| 0.1 mV/pC sensitivity range | 1 mV/pC sensitivity range | 10 mV/pC sensitivity range | |||

| 51.2 kSa/s | ±100 mV | -0.12 dB | -0.19 dB | -0.88 dB | |

| 102.4 kSa/s | -0.44 dB | -0.70 dB | -2.88 dB | ||

| 204.8 kSa/s | -1.91 dB | -2.40 dB | -7.43 dB | ||

| 51.2 kSa/s | ±1 V | -0.15 dB | -0.14 dB | -0.86 dB | |

| 102.4 kSa/s | -0.47 dB | -0.52 dB | -2.82 dB | ||

| 204.8 kSa/s | -1.57 dB | -1.86 dB | -7.07 dB | ||

| 51.2 kSa/s | ±10 V | -0.14 dB | -0.14 dB | -0.79 dB | |

| 102.4 kSa/s | -0.45 dB | -0.51 dB | -2.66 dB | ||

| 204.8 kSa/s | -1.50 dB | -2.81 dB | -6.84 dB | ||

|

Crosstalk Measured with 0.1 mV/pC sensitivity range |

Input Range (Peak) | Guaranteed Range | Typical | ||

| ±100 mV | 83 dB | 88 dB | |||

| ±1 V | 93 dB | 98 dB | |||

| ±10 V | 90 dB | 95 dB | |||

|

Crosstalk Measured with 1 mV/pC sensitivity range |

Input Range (Peak) | Guaranteed Range | Typical | ||

| ±100 mV | 60 dB | 65 dB | |||

| ±1 V | 83 dB | 88 dB | |||

| ±10 V | 85 dB | 90 dB | |||

|

Crosstalk Measured with 10 mV/pC sensitivity range |

Input Range (Peak) | Guaranteed Range | Typical | ||

| ±100 mV | 41 dB | 46 dB | |||

| ±1 V | 62 dB | 67 dB | |||

| ±10 V | 67 dB | 72 dB | |||

CHG42S Specifications

2 Dynamic range

calculated at sampling rate of 51.2 kSa/s, with a 4096-point

FFT.

Specification number: SP160200, Release 1.8. The Module settings

and measurement conditions that were used during specification

measurements are available on request.

Functionality per Channel

WARNING

When using Endevco cables it is recommended to remove the rubber O-ring on the CHG42S Module 10-32 connector as this could cause an intermittent electrical connection between the pin on the cable and the Module connector.

The CHG42S offers 4 grounding options. The grounding options are provided for reducing electromagnetic interference (EMI) that might be present on the sensor cables.

| Module | Cable Shield Connected | Industry Name | Shield to Chassis |

|---|---|---|---|

| *Floating | *No | Floating | 1 MΩ + 10 kΩ |

| Floating | Yes | - | 10 kΩ |

| Grounded | No | - | 1 MΩ |

| Grounded | Yes | Single-Ended | ~20 Ω |

Grounding options

*Default setting on Module startup. This combination provides a path for Electrostatic Discharge (ESD) to slowly discharge and will provide some protection against rapid ESD events that could damage the sensitive charge inputs.

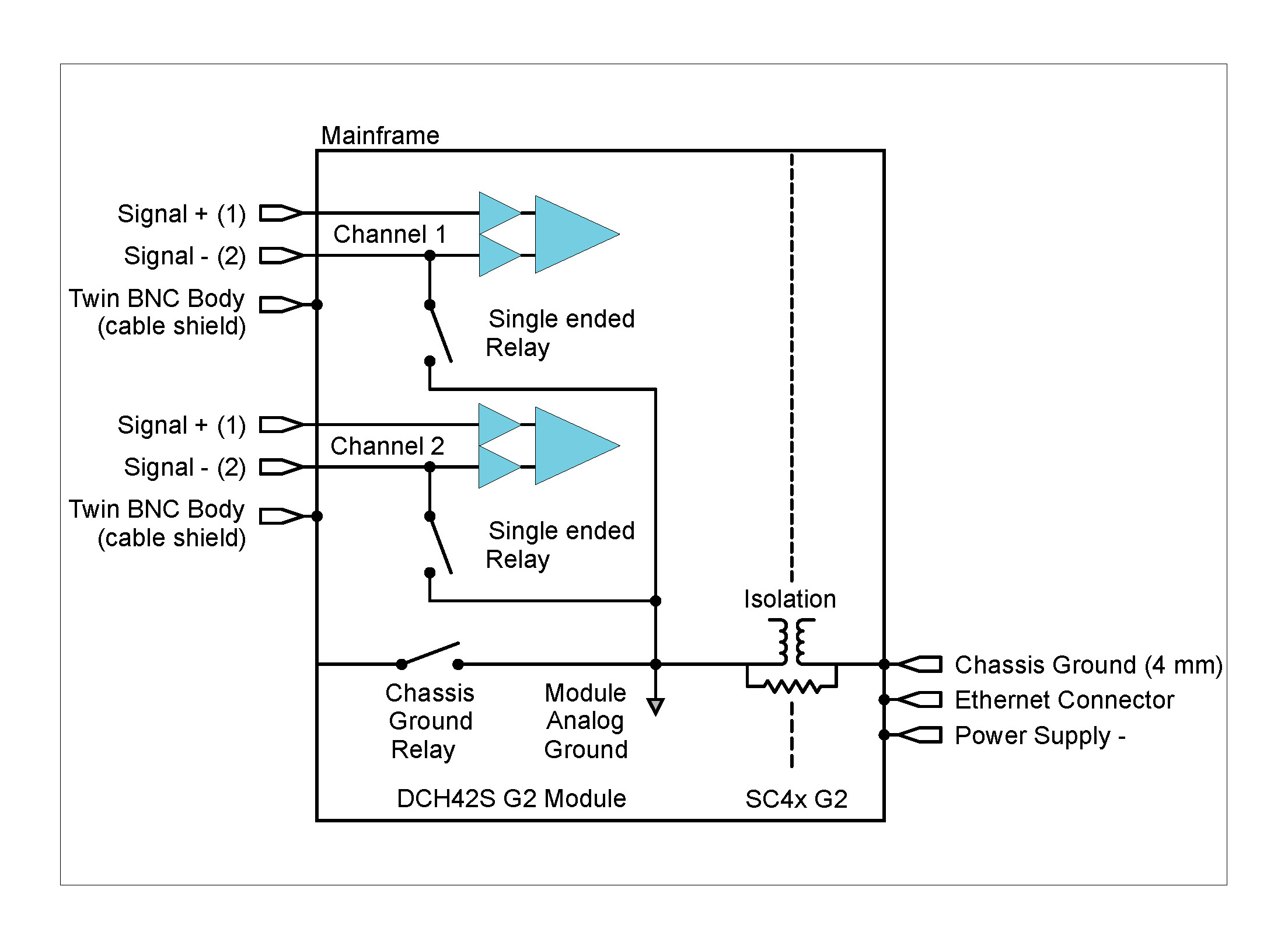

Description

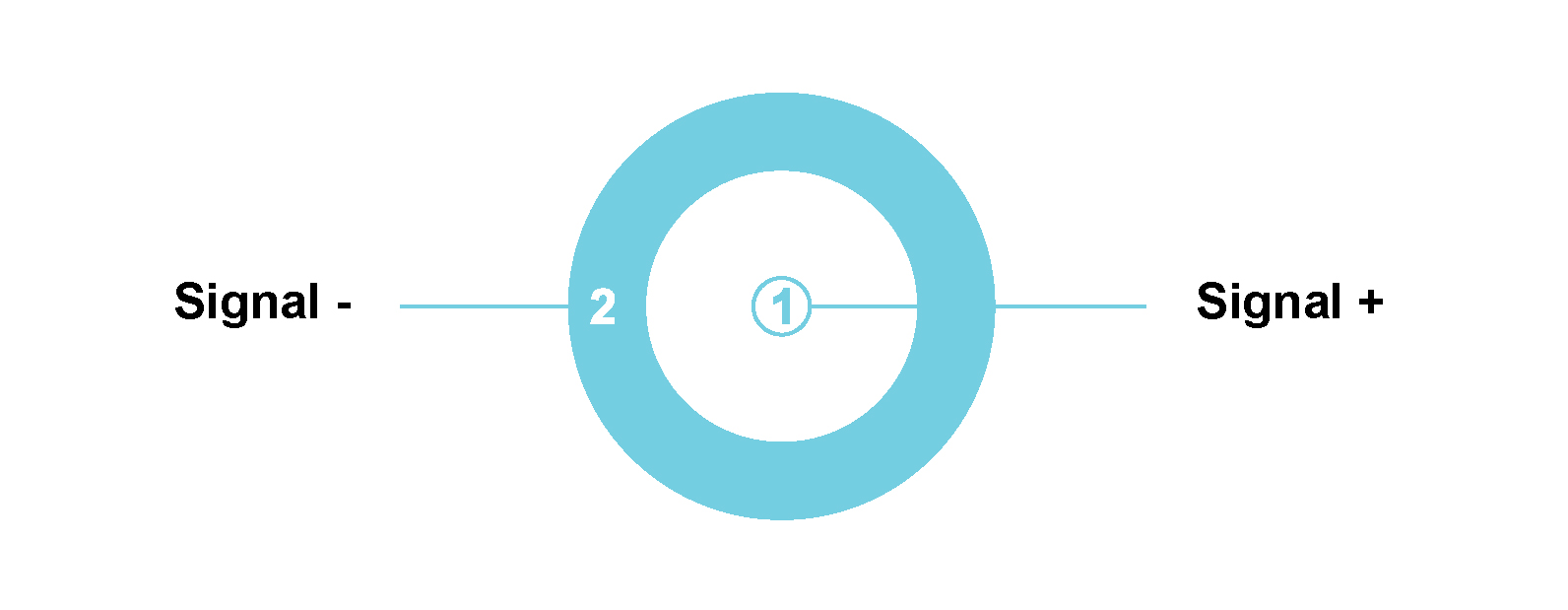

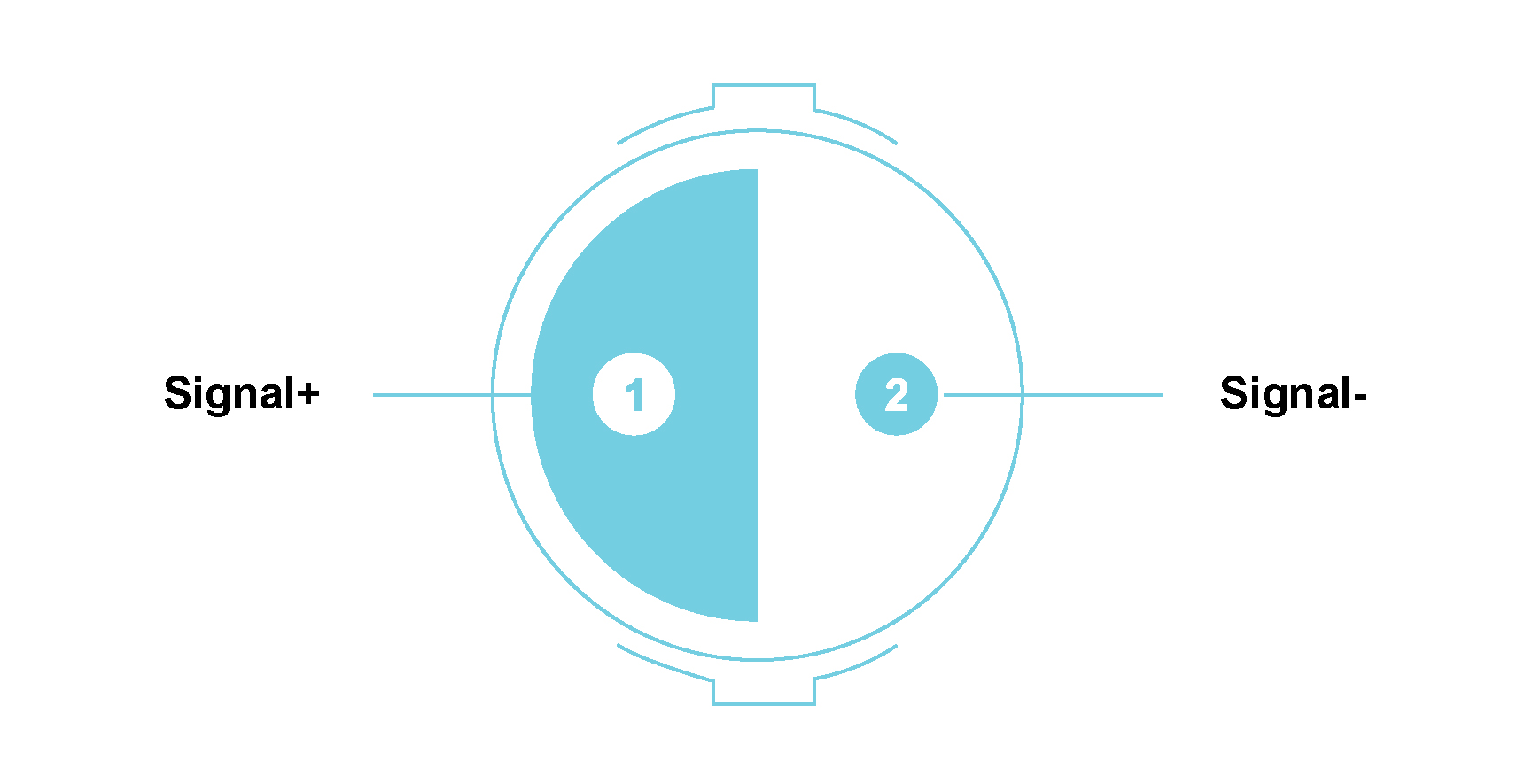

The DCH42S Module has 2 independent differential input channels for Quartz or Piezoelectric Ceramic sensors. These sensors are typically used when improved signal performance such as low noise and low distortion is required or where high temperature and nuclear radiation prevents the use of ICP® based sensors. Additionally, a differential charge measurement offers further noise immunity and higher bandwidth and is particularly suited to applications using long cables. The Module can be used:

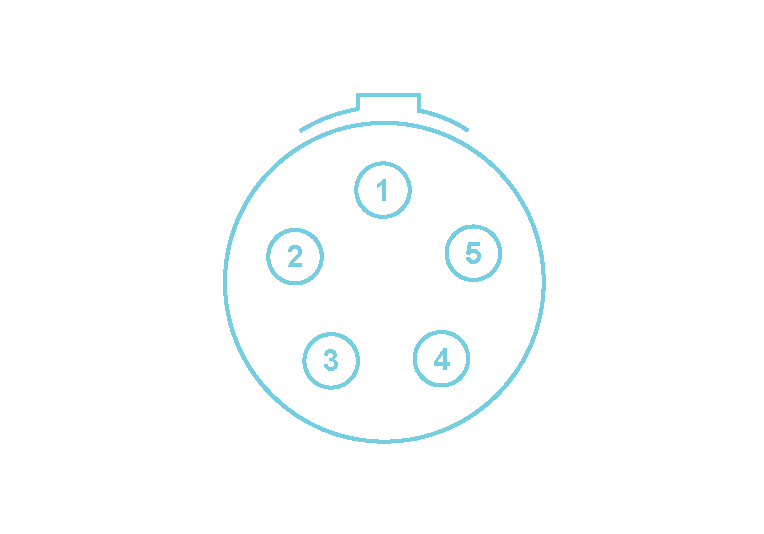

| Front Panel | Connector Information and Pin Definitions |

|---|---|

|

|

DCH42S with 31-2225 twin BNC connectors Module Pin Definition (when looking into the front panel’s connector or at the rear of the cable’s connector)

ESD WARNING

The DCH42S Module inputs are sensitive to ESD damage. Always take care to discharge any additional static electricity that might have built up on a cable and connector before making contact with the DCH42S Module.

Features

Please note:The features and specifications may vary based on the software package utilized with the DECAQ

DCH42S Specifications

| Interface | For piezoelectric sensors | ||

| Voltage Amplifier Ranges | ±100 mV, ±1 V, ±10 V (peak) | ||

| Input Charge Ranges | Single-Ended Mode | 0.1 mV/pC | ±100 000 pC (peak) |

| 1 mV/pC | ±10 000 pC (peak) | ||

| Differential Mode | 0.2 mV/pC | ±5 000 pC (peak) | |

| 2 mV/pC | ±50 000 pC (peak) | ||

| -3dB High Pass Frequency | Single-Ended Mode | 0.1 mV/pC | 0.16 Hz or 0.016 Hz |

| 1 mV/pC | 1.6 Hz or 0.16 Hz | ||

| Differential Mode | 0.2 mV/pC | 0.16 Hz or 0.016 Hz | |

| 2 mV/pC | 1.6 Hz or 0.16 Hz | ||

|

Phase Accuracy Channels in similar range |

Typical1 | < 0.5° at 10 kHz | |

| Other Sampling Rates | Available through digital LP filters and decimation | ||

| Optional Programmable Digital IIR Filter |

Band pass/stop : 6 dB/octave High/Low pass : 12 dB/octave |

||

| Optional First Order High-Pass Filter | -3 dB @ 1 Hz | ||

| Module Calibration | Internal amplitude calibration | ||

| Protection | 1 kΩ series (inline) | ||

| Galvanic Isolation | 50 V | ||

|

Digital Low-Pass Filter Filter scales with sampling rate |

Passband | fs x 0.45 Hz | |

| Stopband | fs x 0.55 Hz | ||

| Passband Ripple | ±0.005 dB | ||

| Stopband Attenuation | 100 dB | ||

DCH42S Specifications

1 Measured in 10 V range at 204.8 kSa/s

Functionality per Channel

Grounding diagram

Description

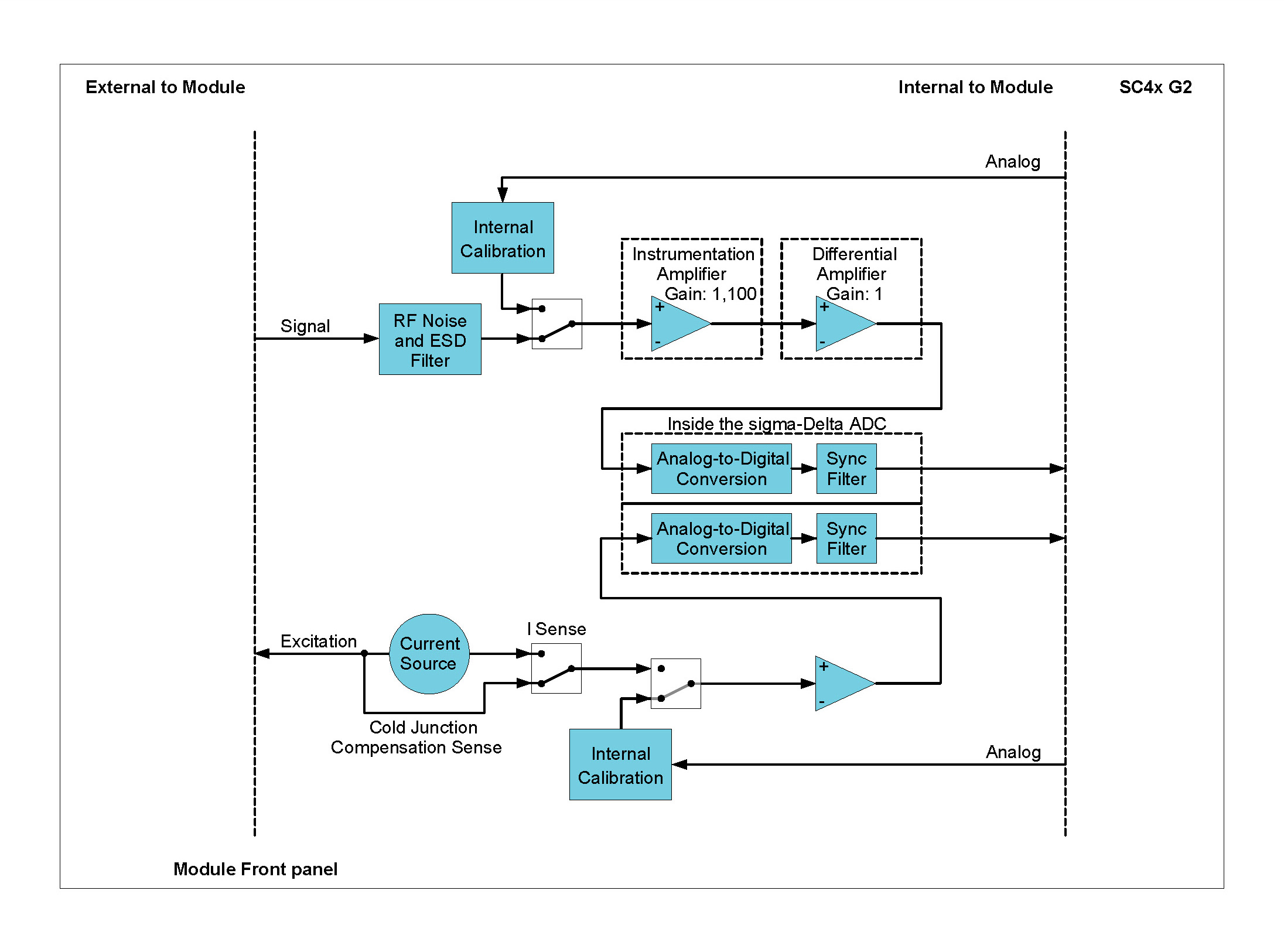

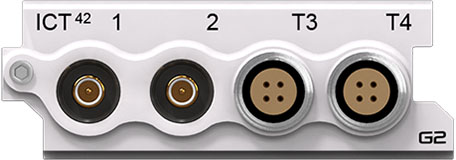

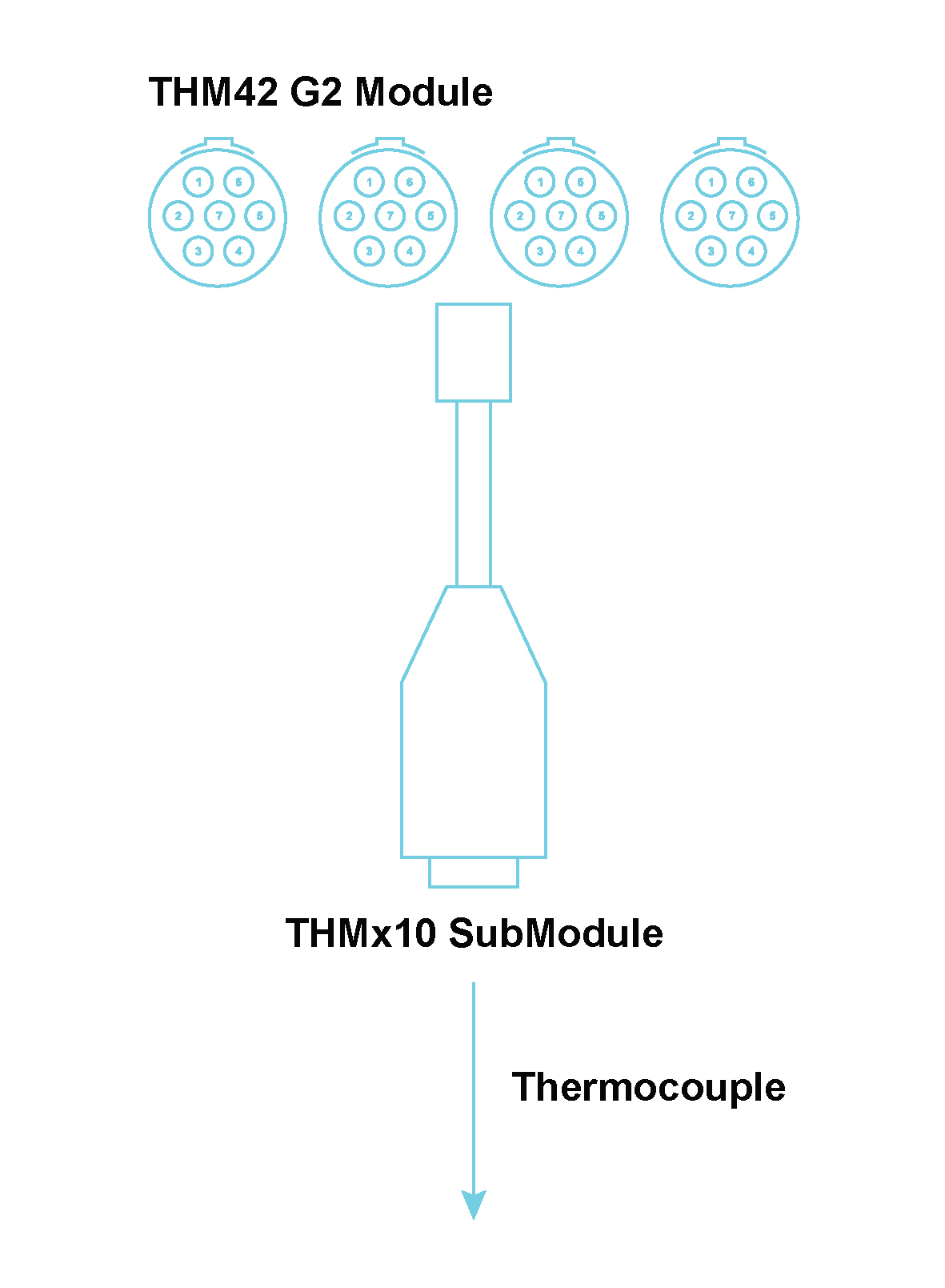

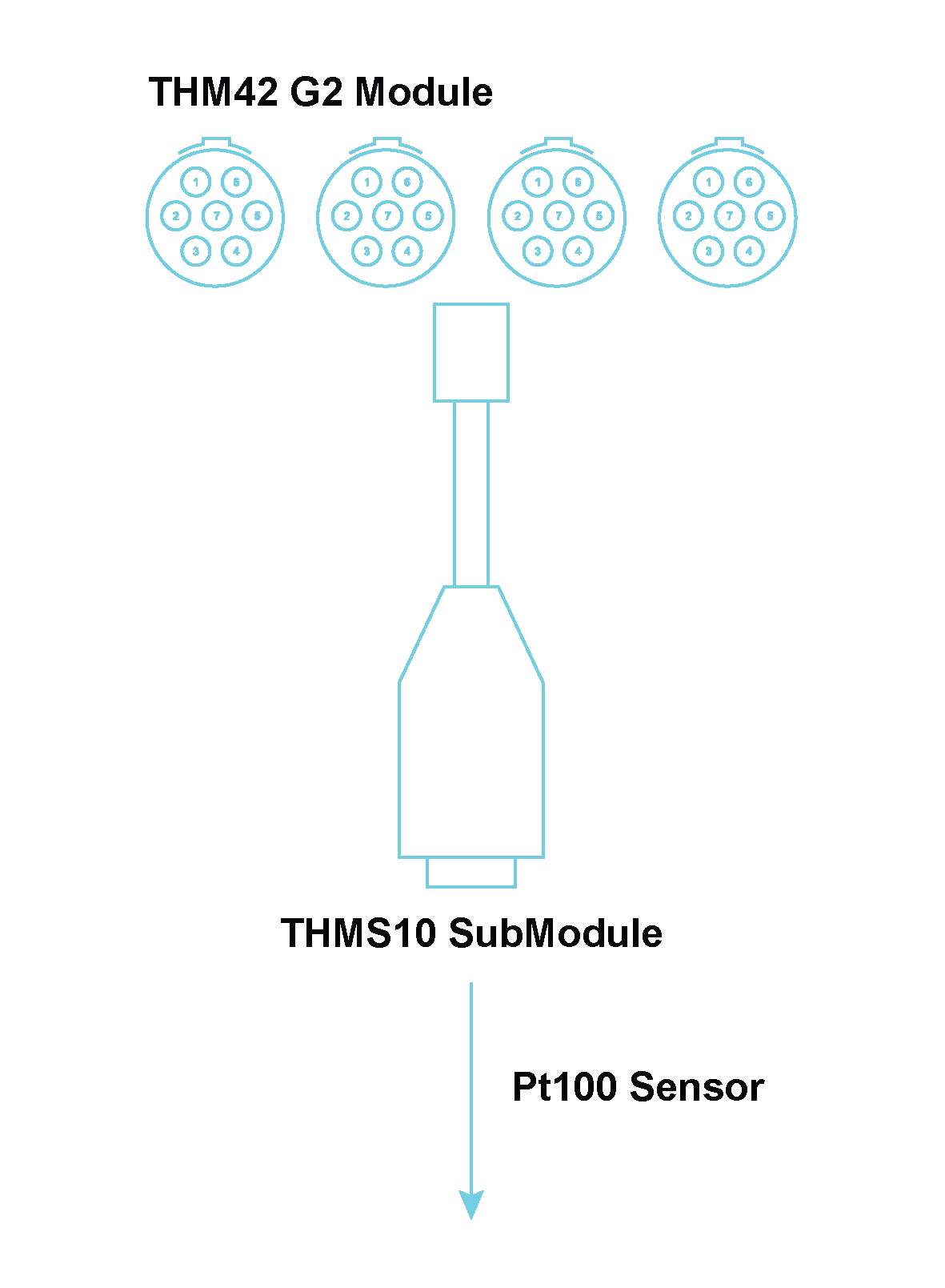

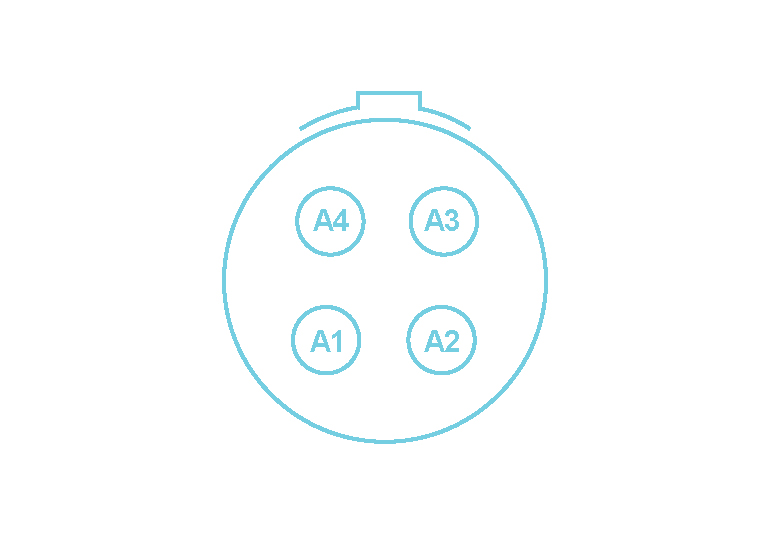

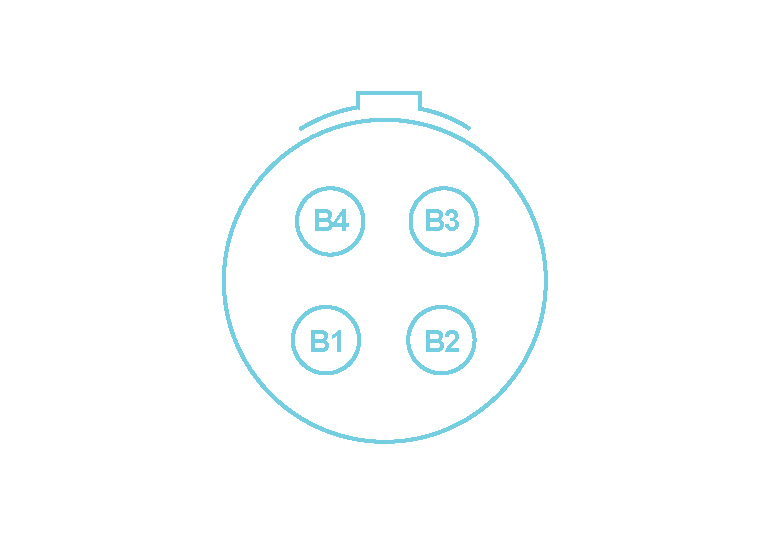

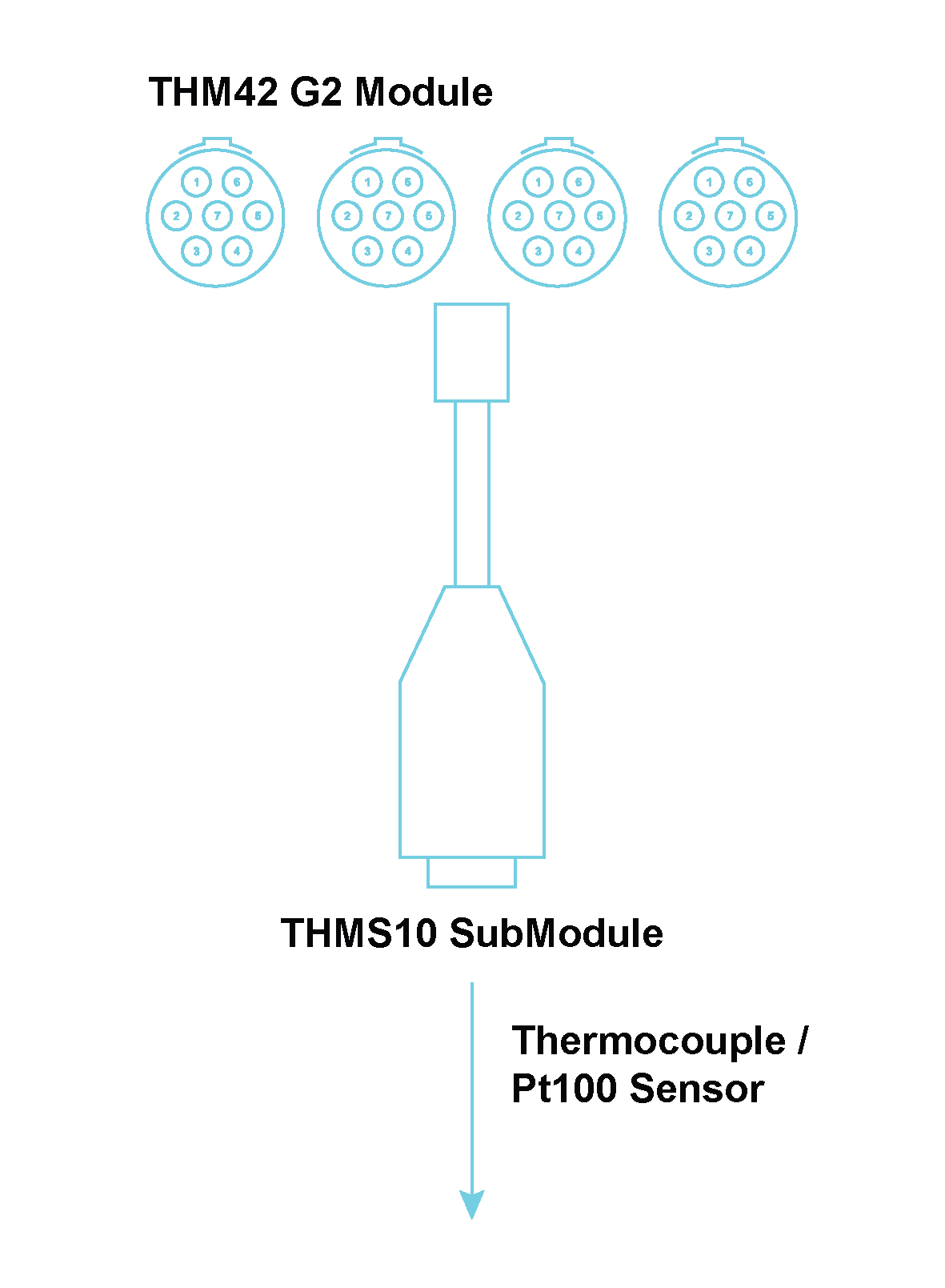

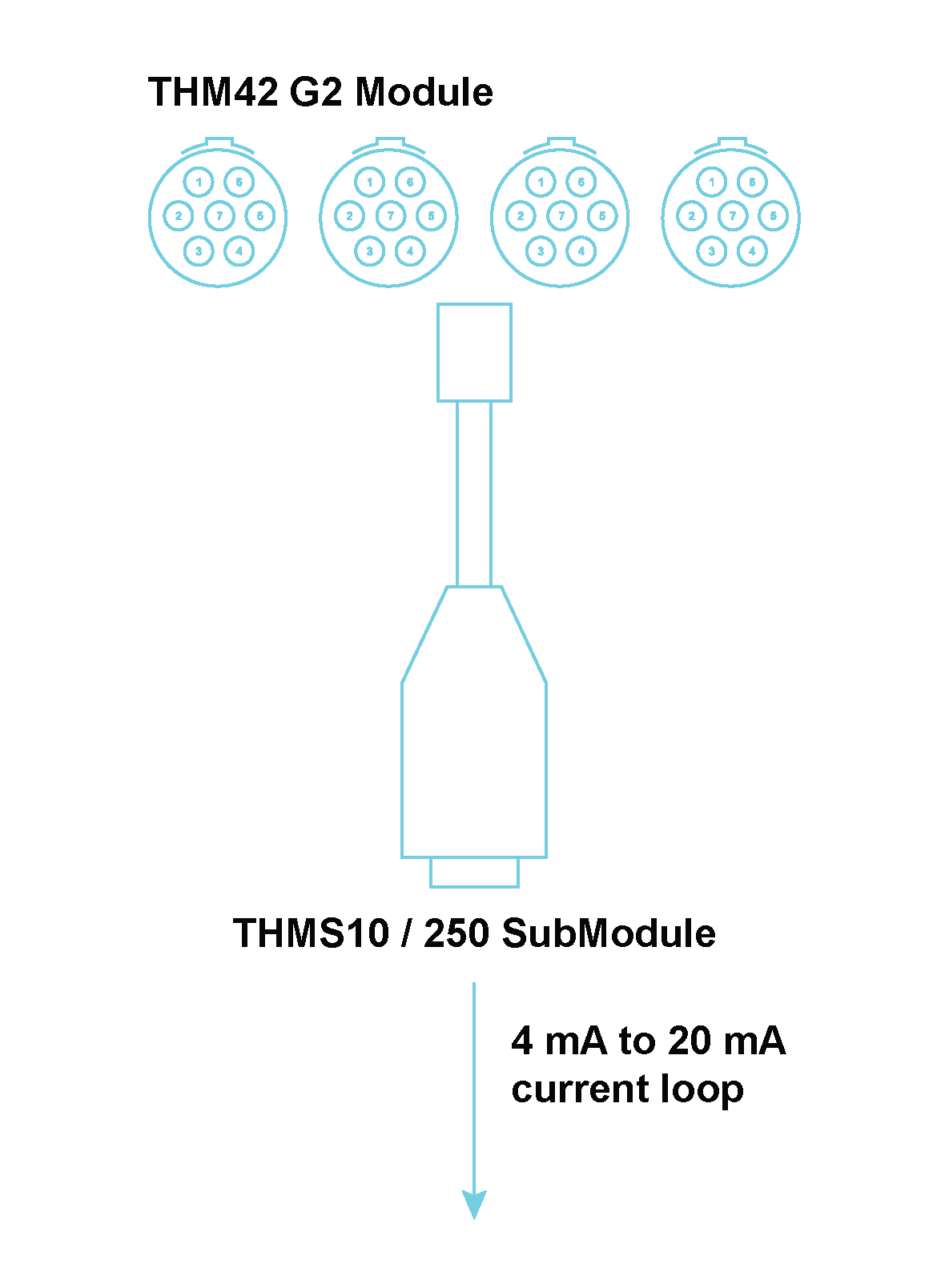

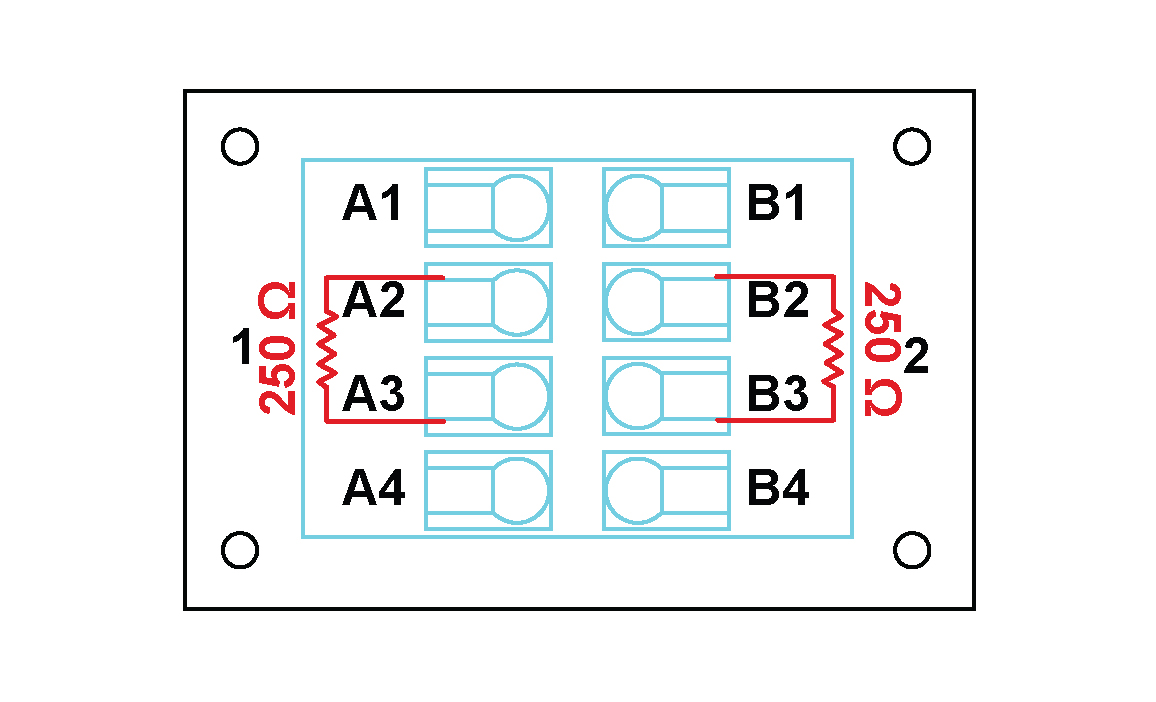

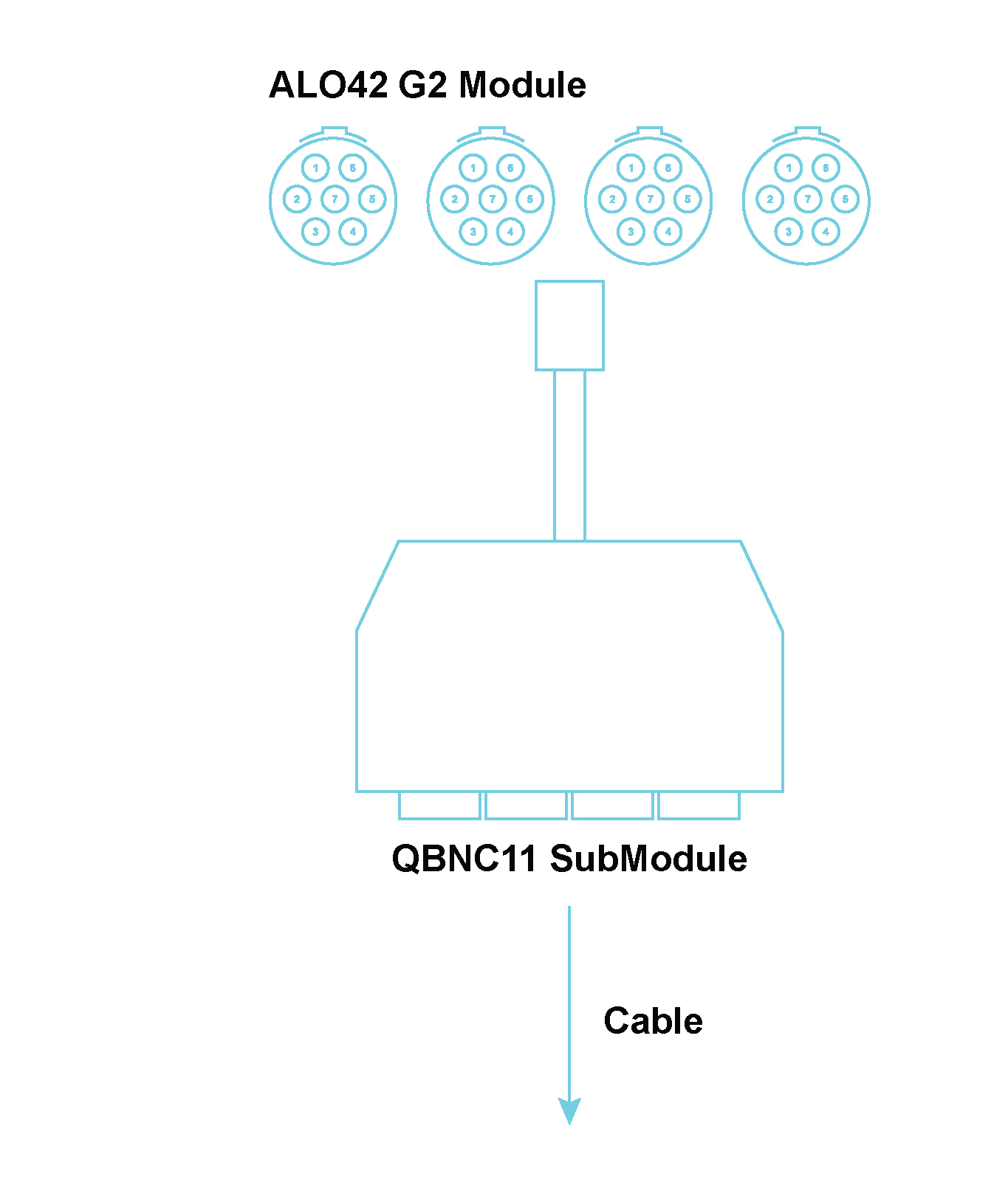

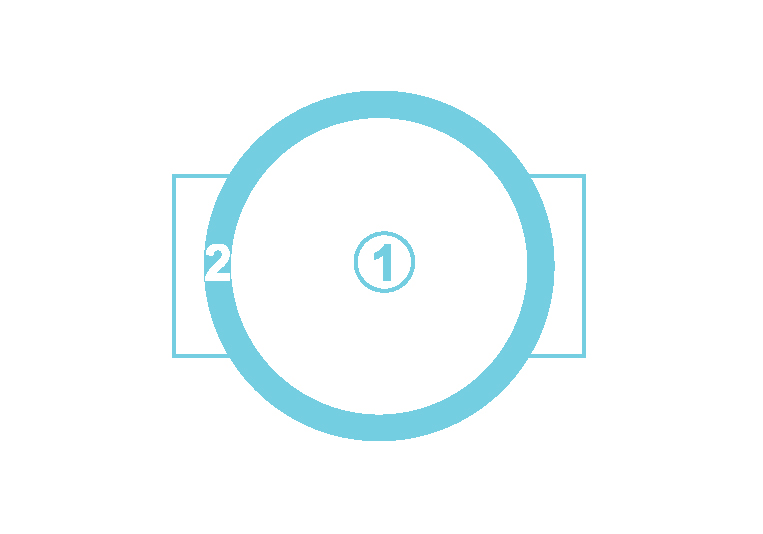

The THM42 Module contains 8 channels for use with any thermocouple type as well as Pt100 sensors. Remote cold junction compensation is provided through a SubModule (which is thermocouple type specific) whilst linearization is provided in the signal conditioning board. The Module also includes a calibrated 0.2 mA current source for Pt100 sensor excitation.

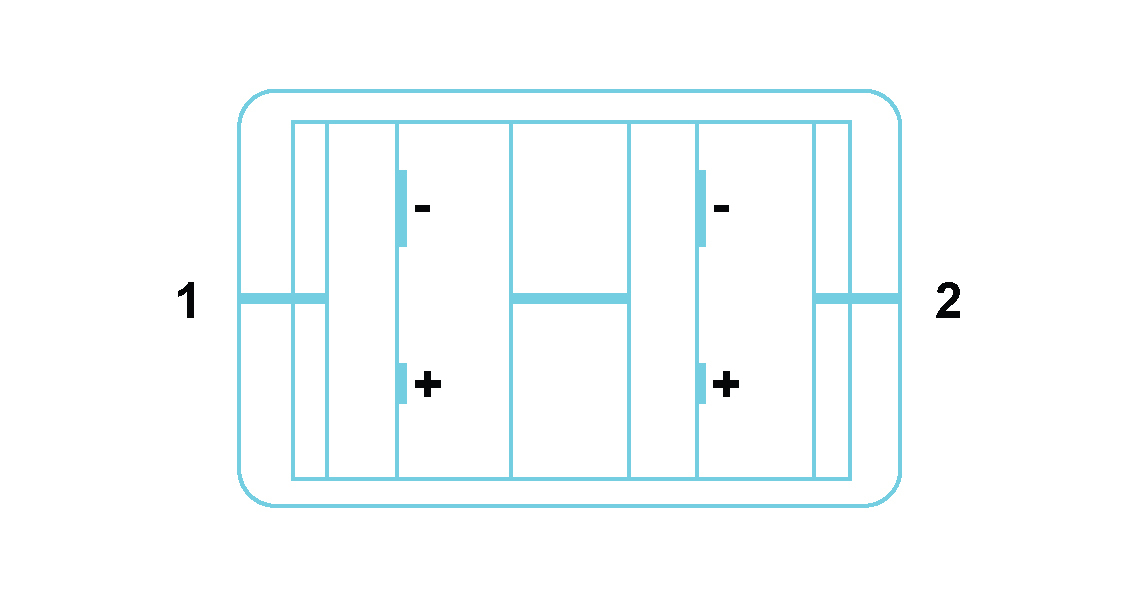

SubModules are used with the Module which contains a pair of commonly used miniature E, J, K, and T thermocouple connectors (other types available upon request) with cold junction circuitry for thermocouple applications. Another SubModule contains a pair of LEMO® connectors for Pt100 applications. Any combination of applicable SubModules can be connected to the THM42 Module.

The THM42 Module also includes 8 channels for measuring voltage inputs up to ±10 V. The Module can be used:

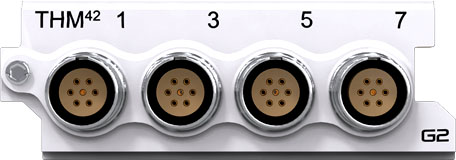

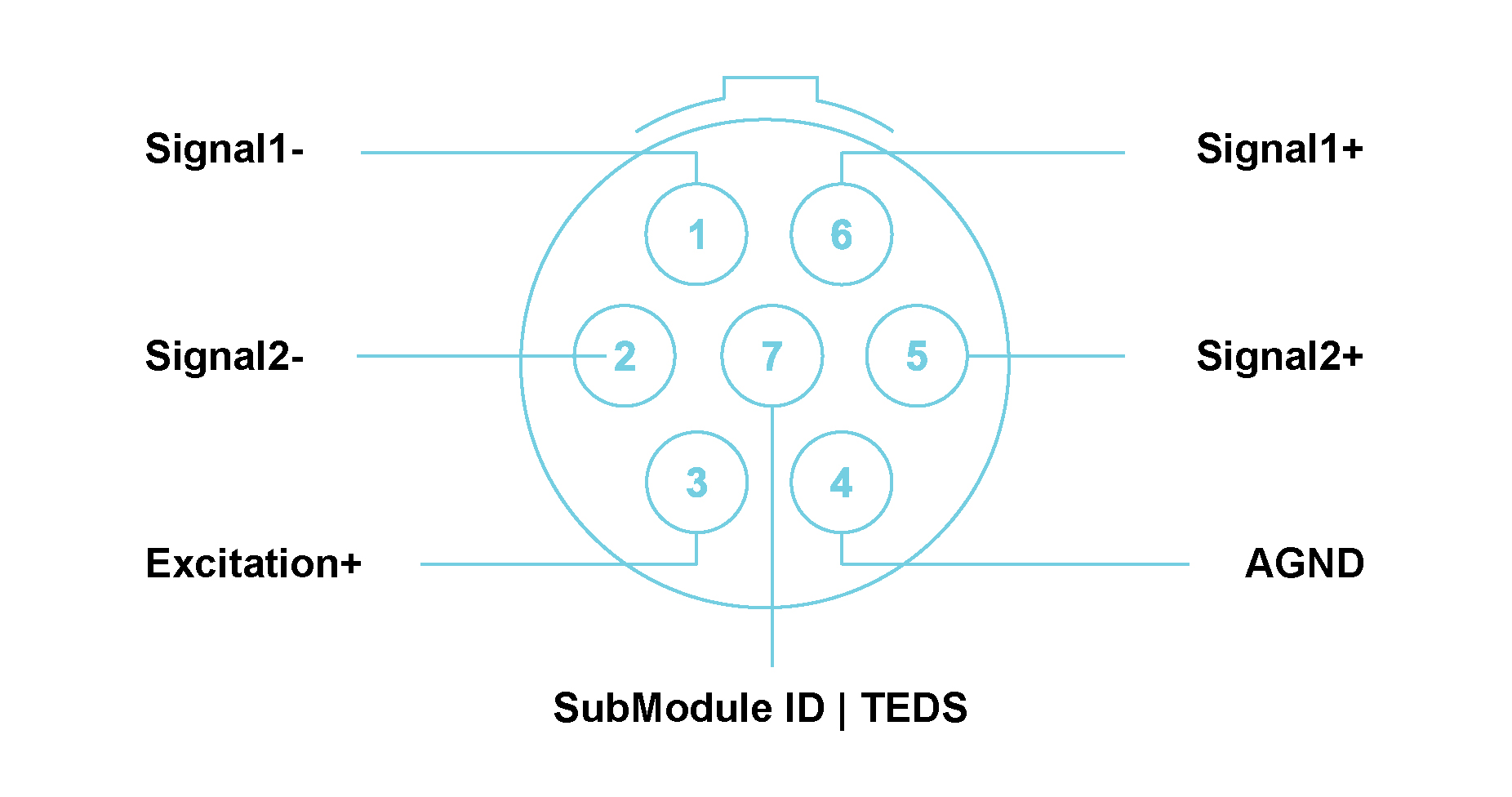

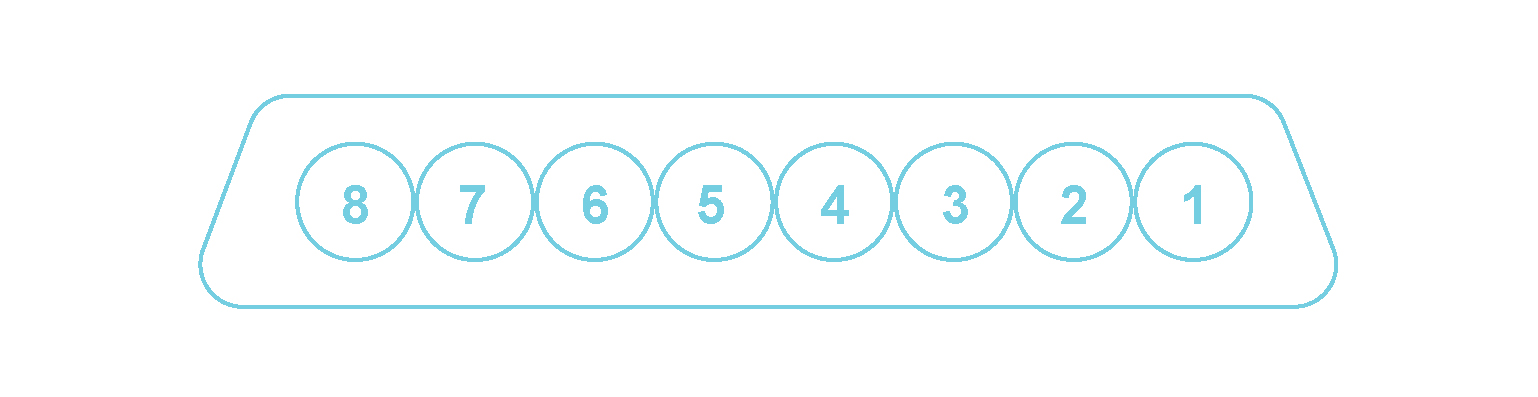

| Front Panel | Connector Information and Pin Definitions |

|---|---|

|

|

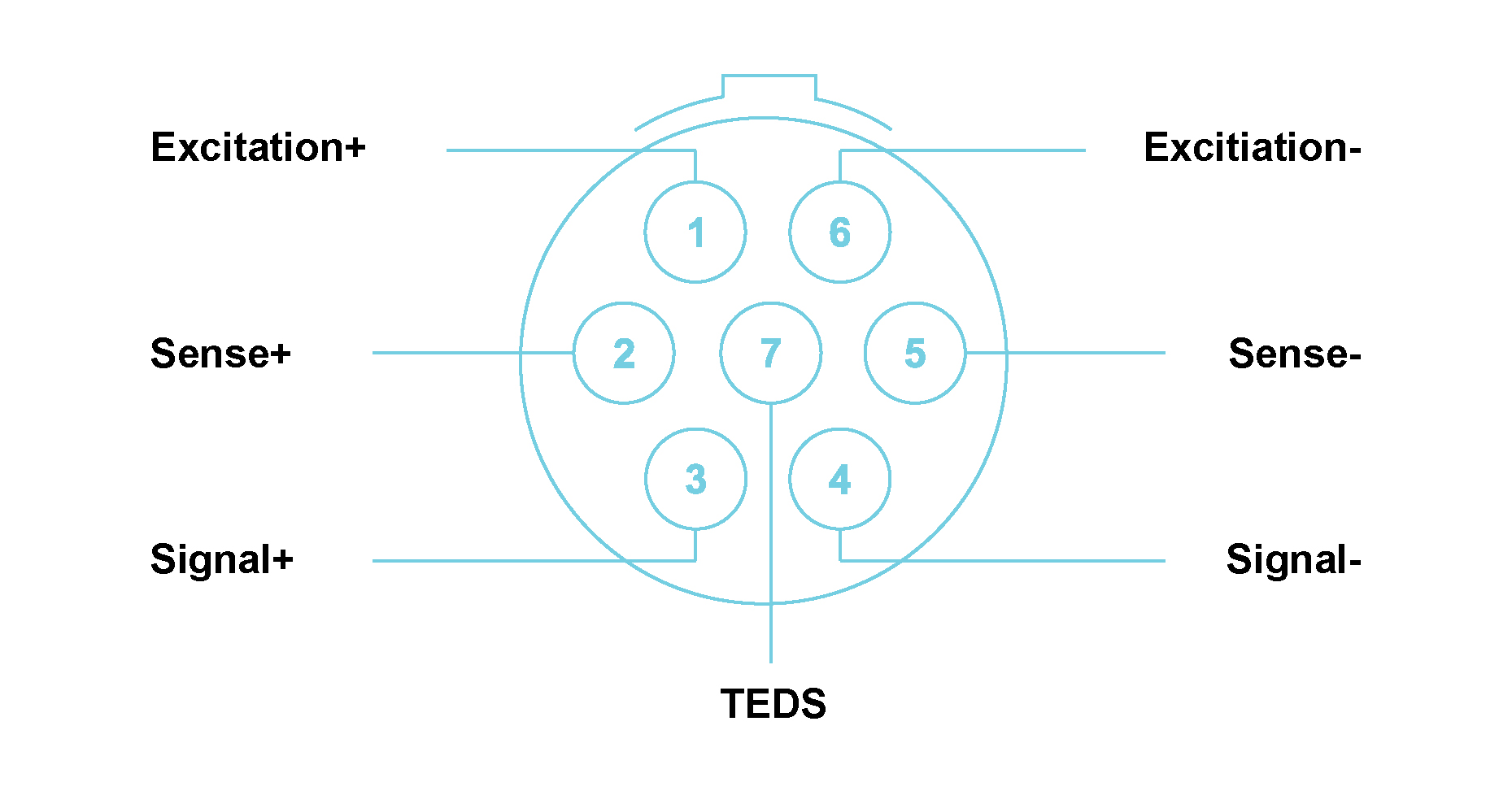

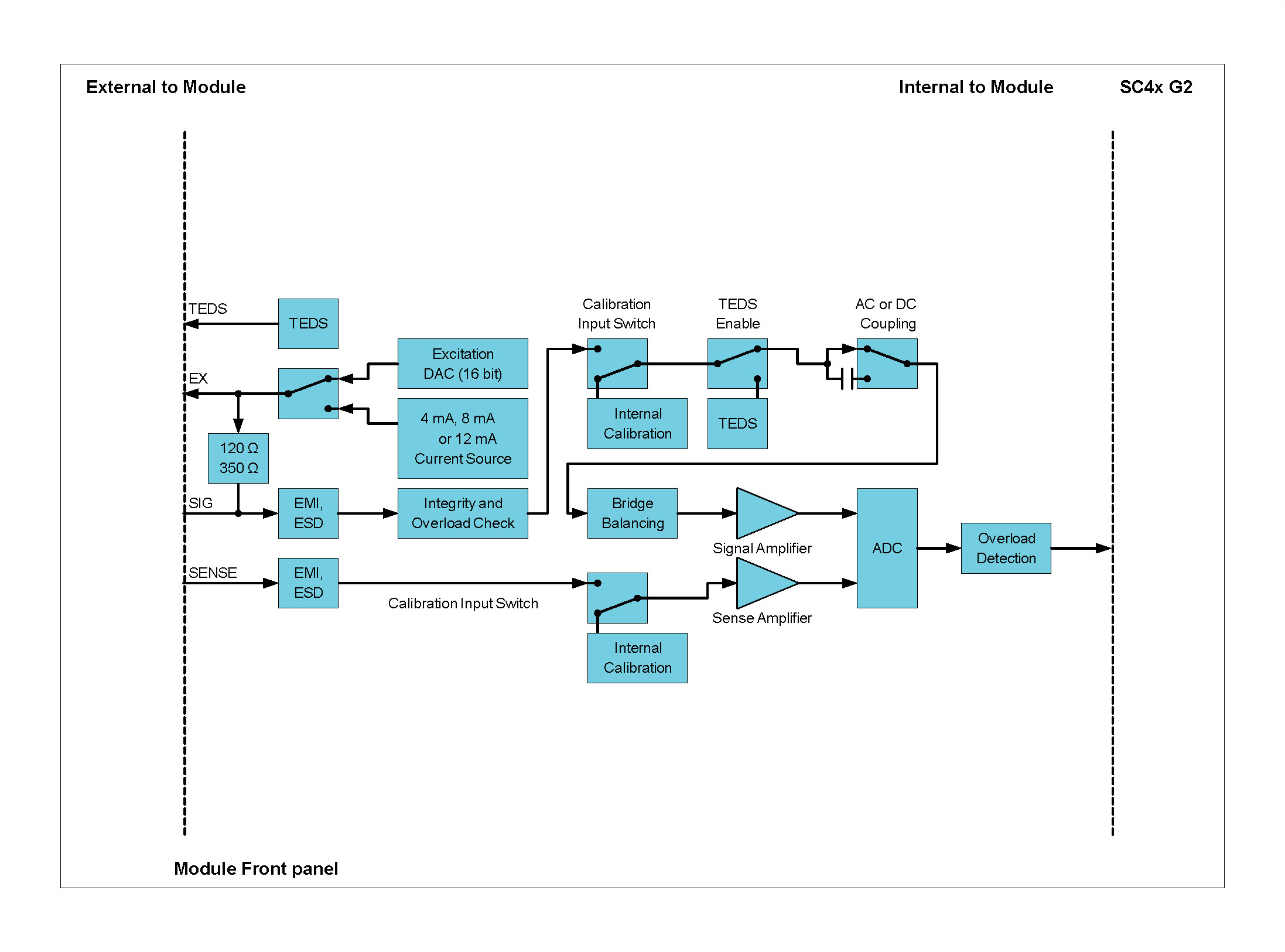

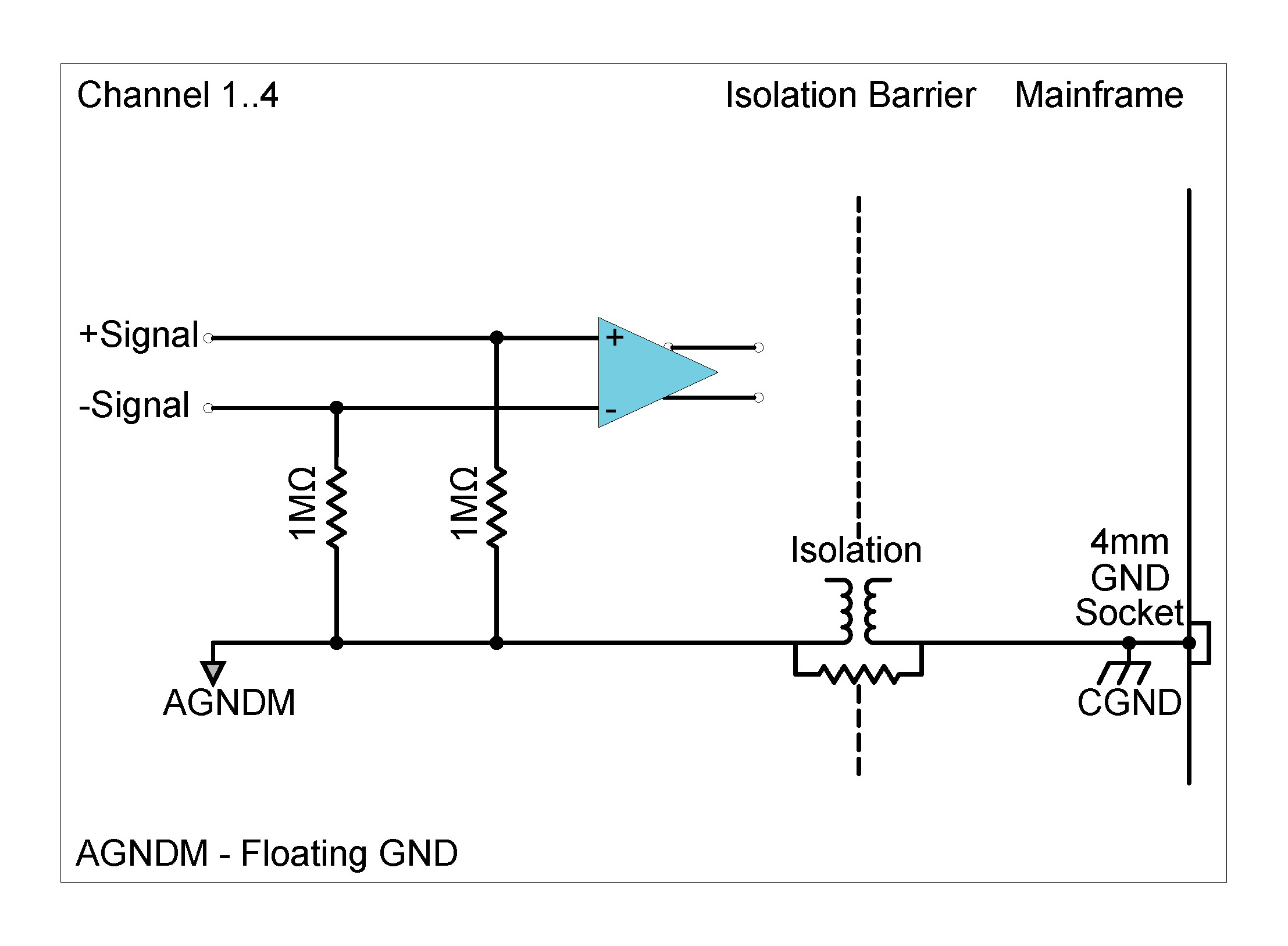

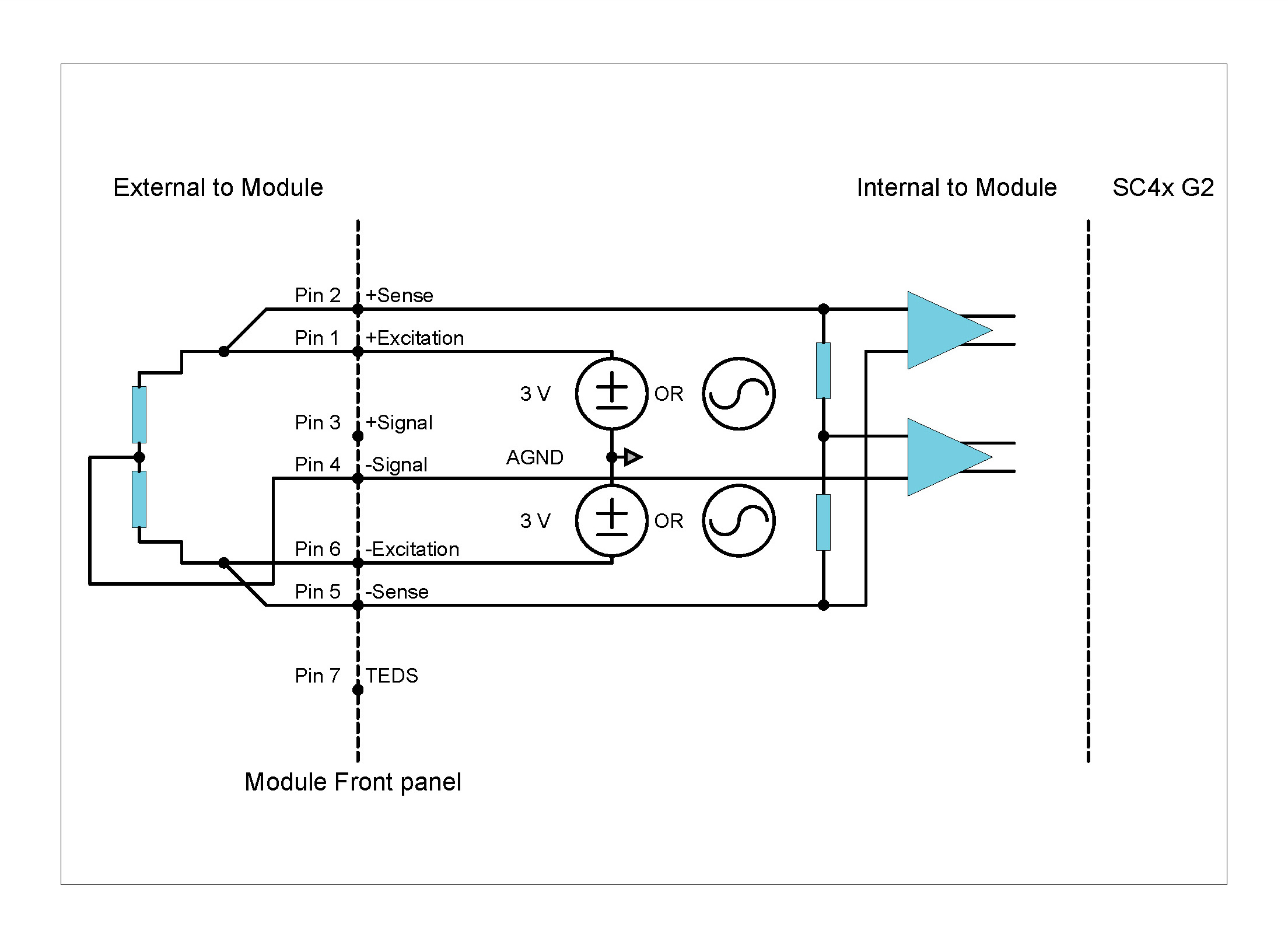

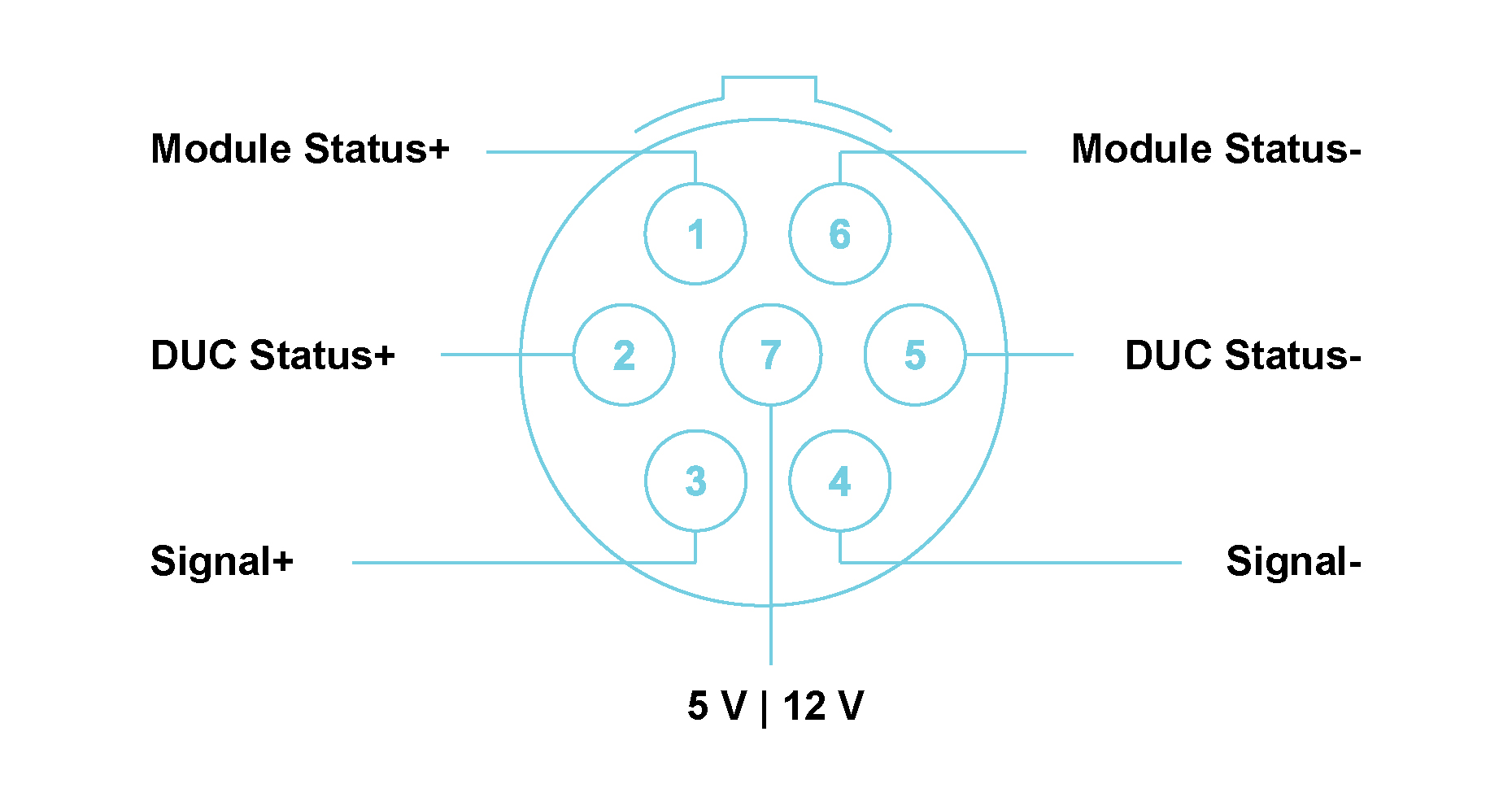

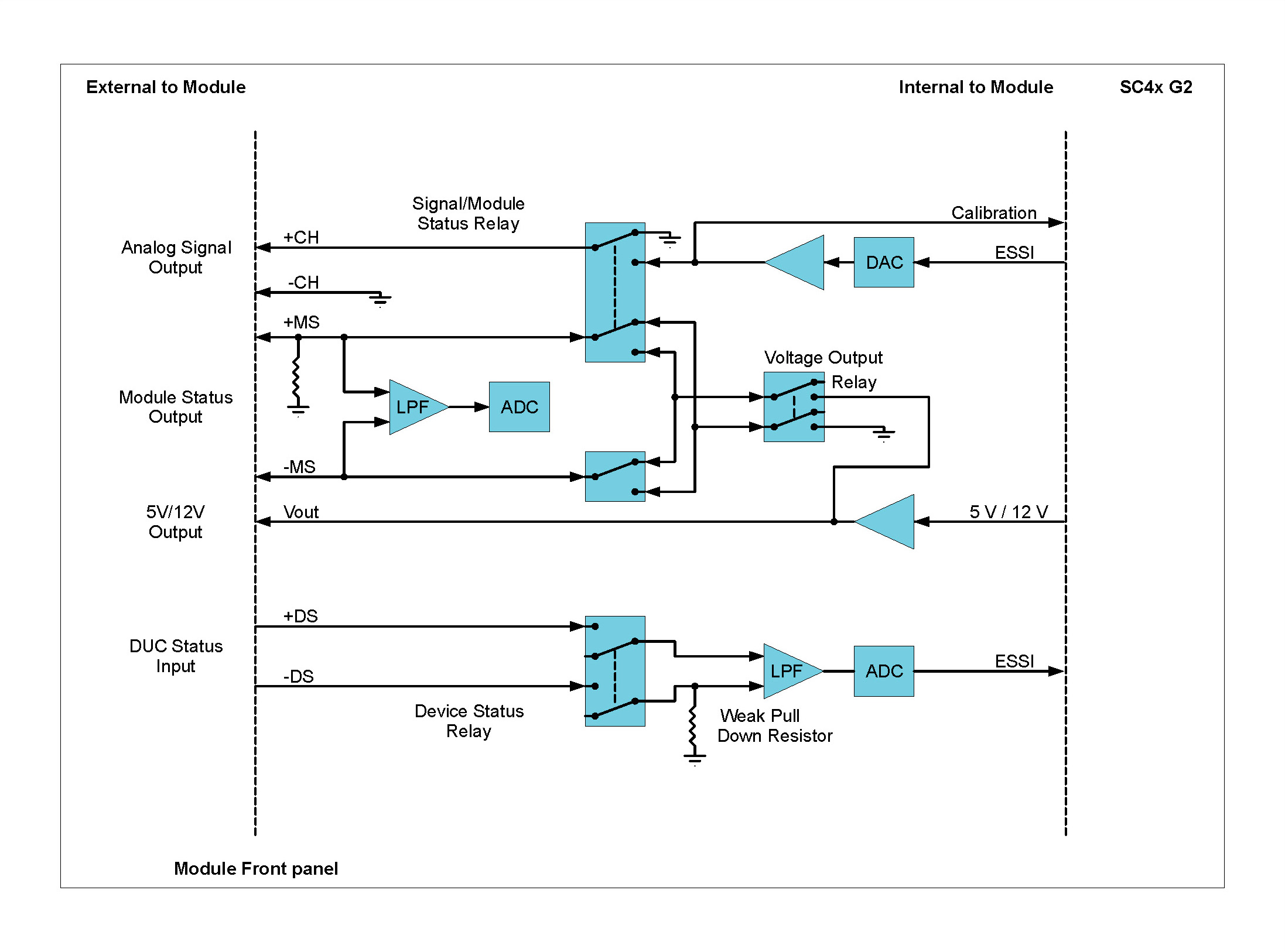

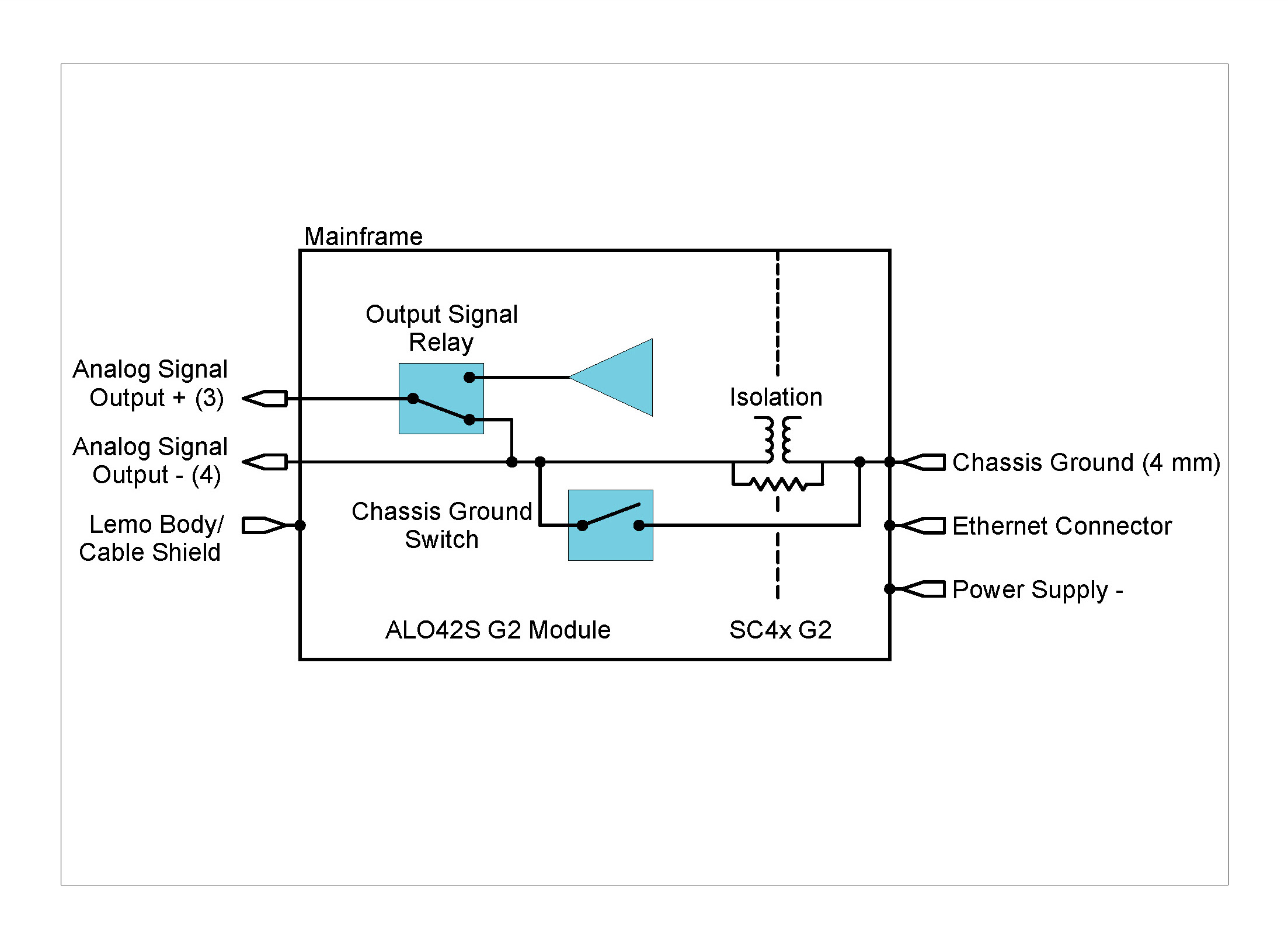

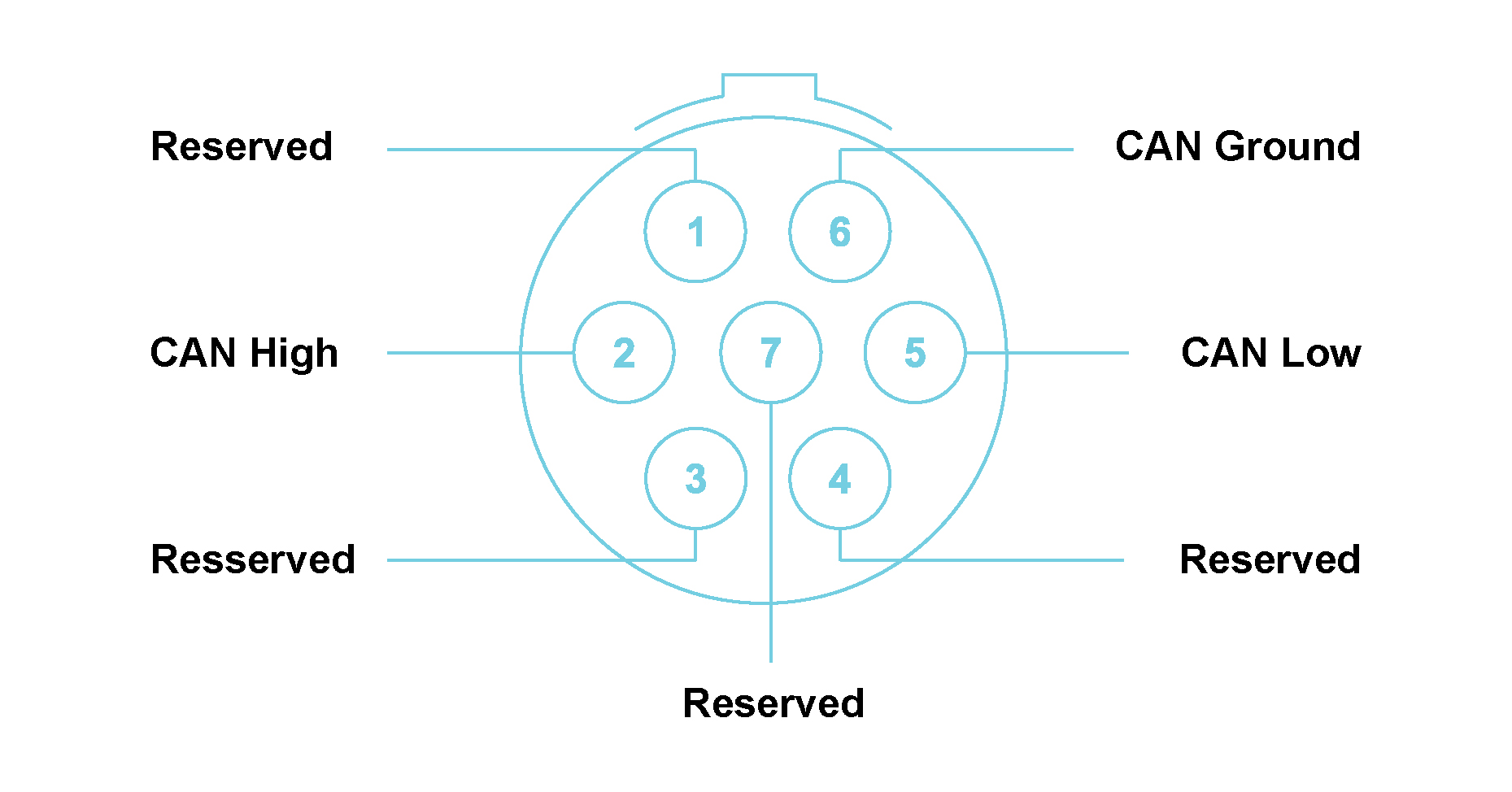

THM42 with LEMO® 7-way EHG.0B Module Pin Definition (when looking into the front panel’s connector or at the rear of the cable’s connector)

Features

Please note:The features and specifications may vary based on the software package utilized with the DECAQ

THM42 Specifications

| Input Modes | Thermocouple and Pt100 | |

| Sensors | Any combination of thermocouple and Pt100 but the same type of sensor must be used for each channel pair | |

| Linearization |

Thermocouple linearization for types: Chromel®/Constantan (E, NiCr-CuNi) Iron/Constantan (J, Fe-CuNi) Chromel®/Alumel® (K, NiCr-NiAl) Copper/Constantan (T, Cu-CuNi) |

|

| Excitation | 0.2 mA Excitation current for Pt100 and cold-junction-compensation. Monitored internally for drift and offset errors. | |

| Maximum Common Mode Voltage | ±7 V | |

| Other Sampling Rates | Available through digital LP filters and decimation | |

| SubModules | Cable between Module and sensor wire with housing containing TEDS, cold-junction-compensation and sensor connector. Colour-coded according to thermocouple type. | |

| Module Calibration | Internal amplitude and phase calibration | |

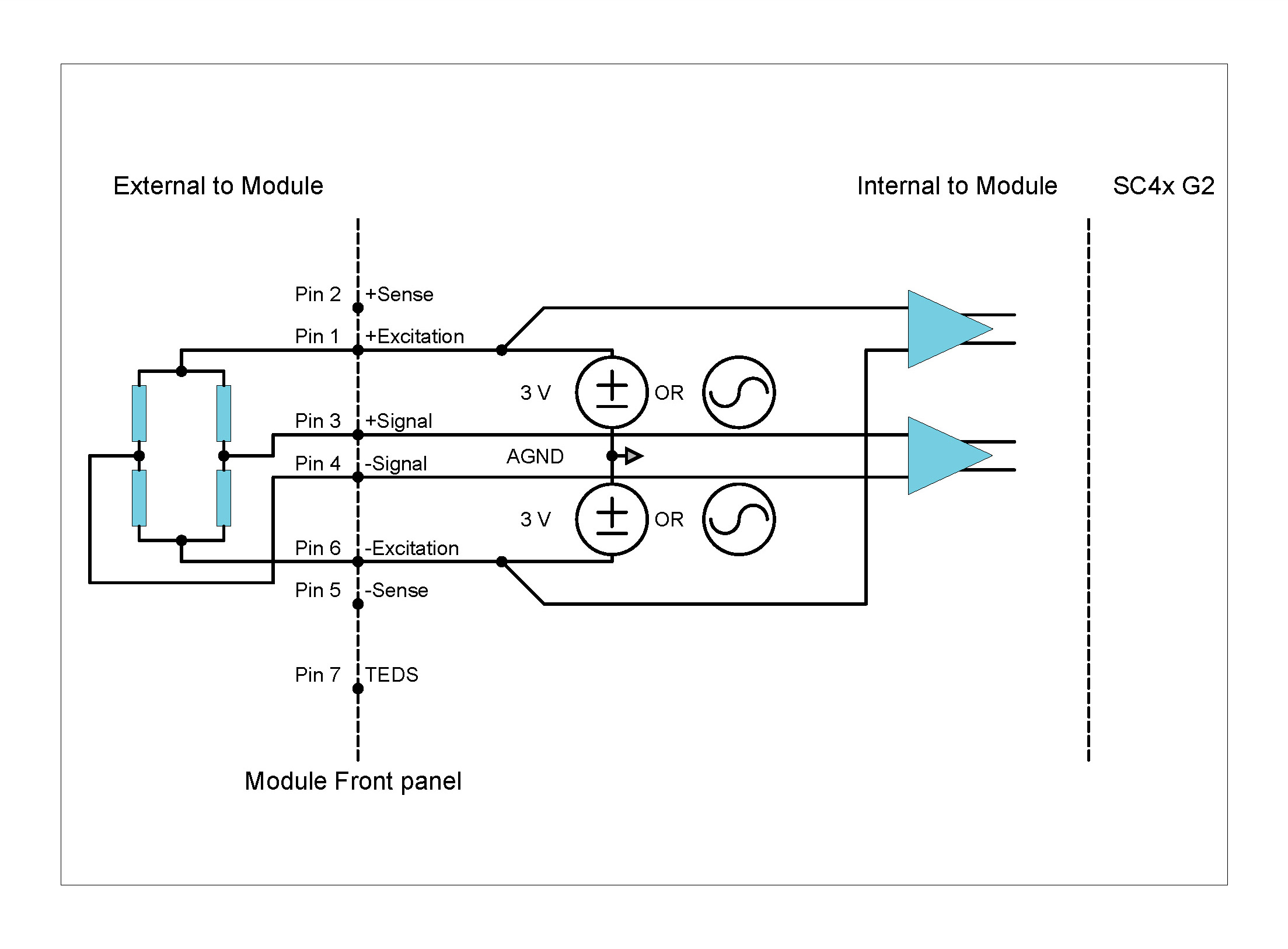

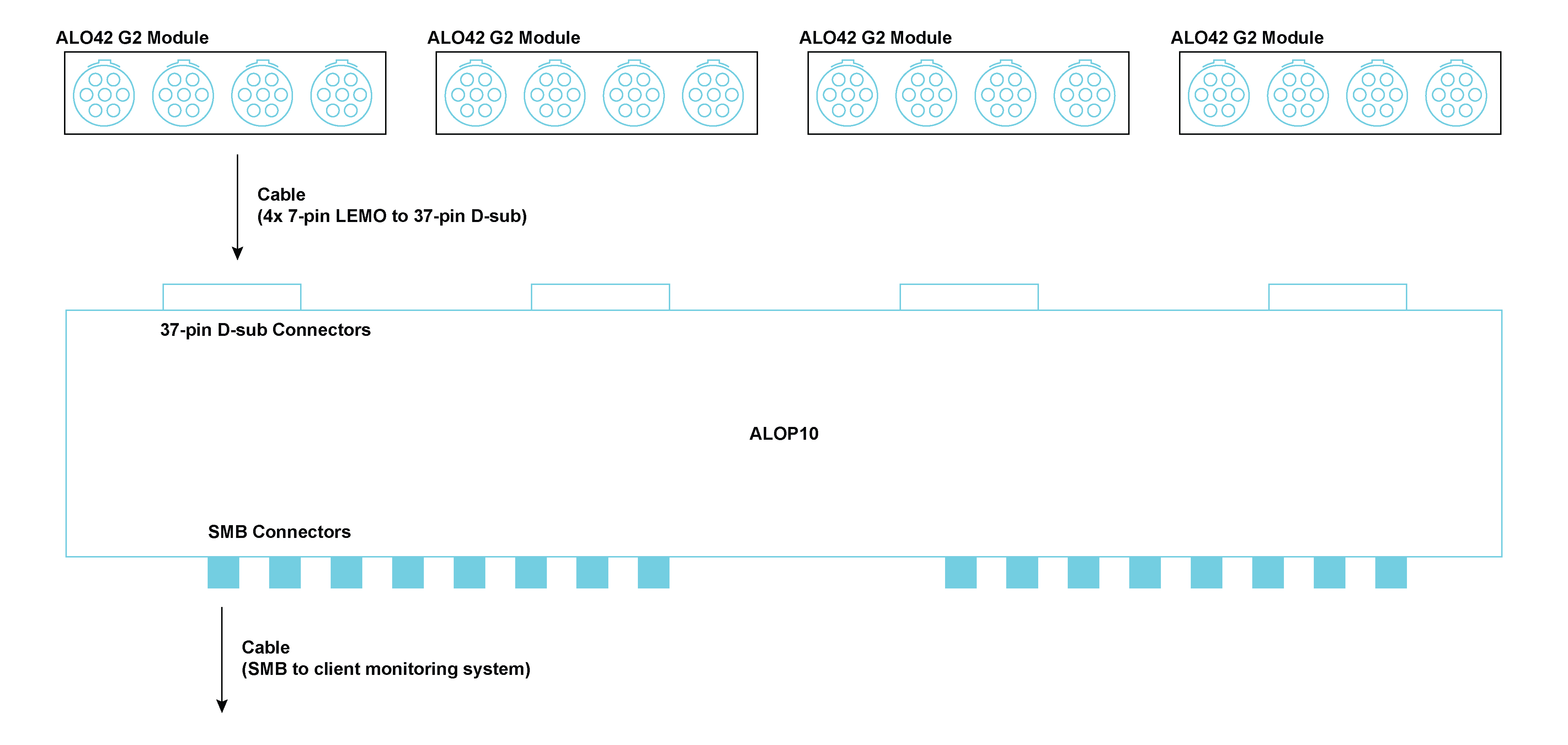

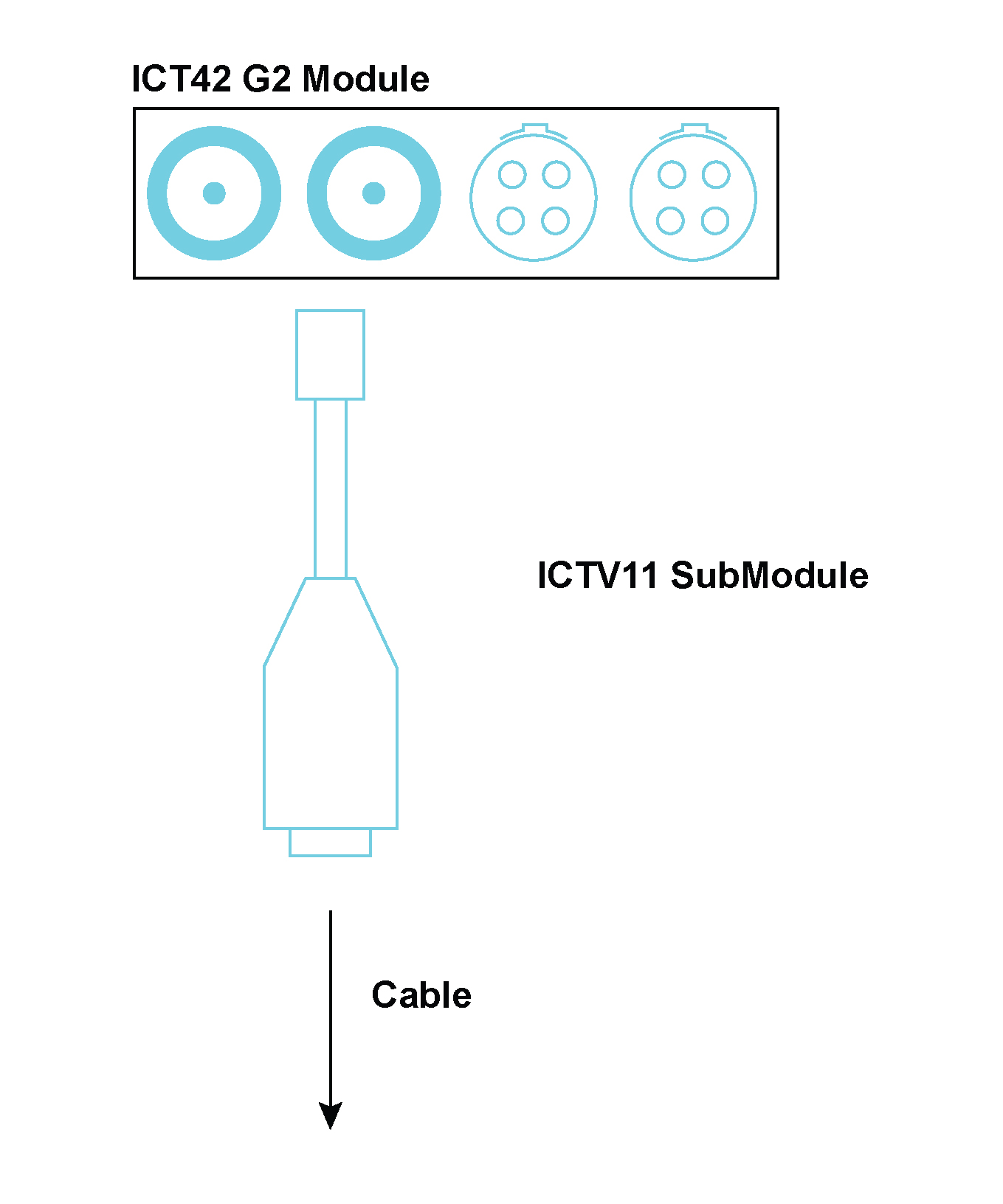

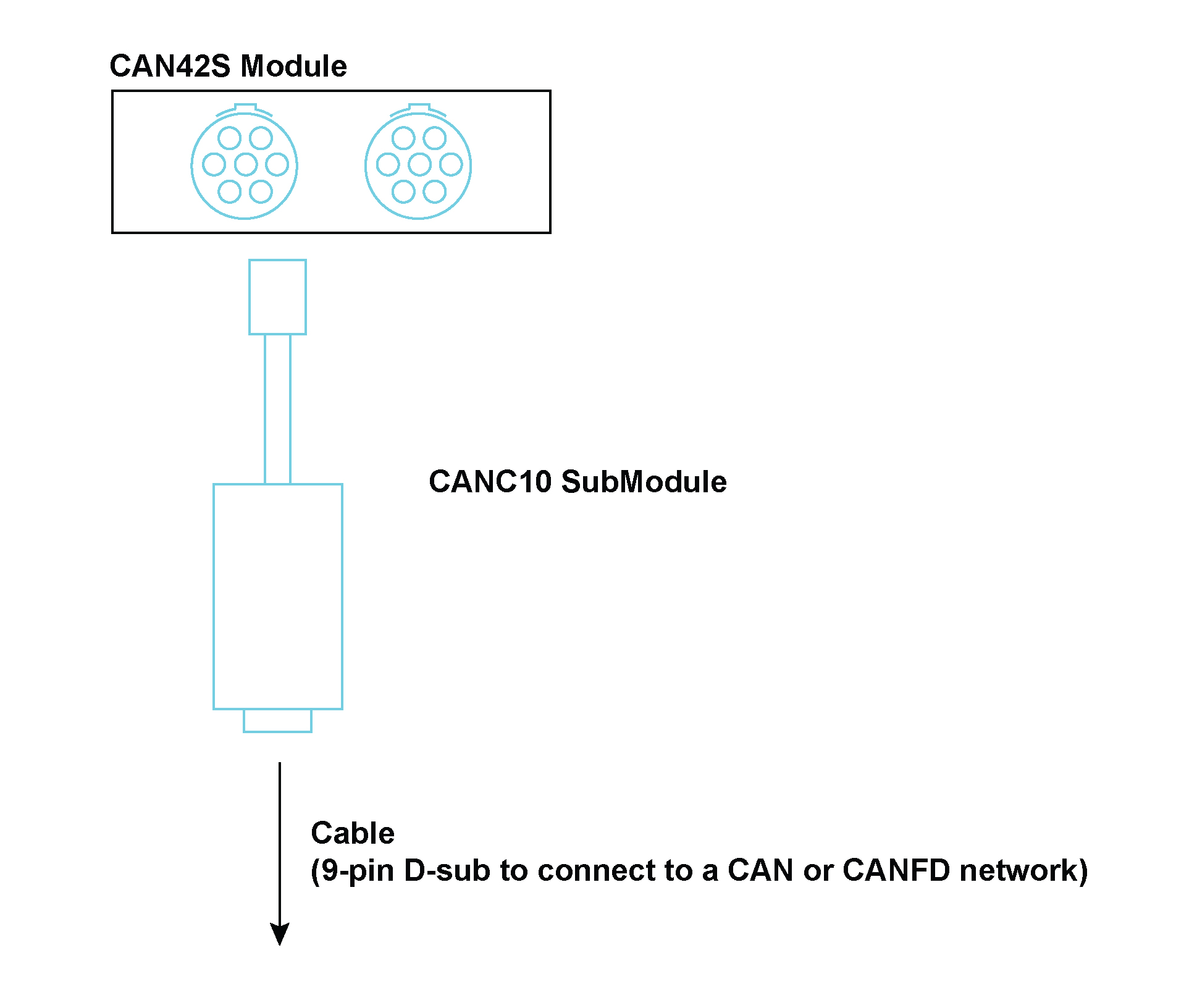

|